Isuzu N-Series. Service manual - part 534

Engine Electrical 6D-3

Battery

General Description

There are six battery fluid caps at the top of the battery.

Diagnosis

Visual Inspection

Inspect the battery for obvious physical damage, such

as a cracked or broken case, which would permit

electrolyte loss.

Replace the battery if obvious physical damage is

discovered during inspection.

Check for any other physical damage and correct it as

necessary.

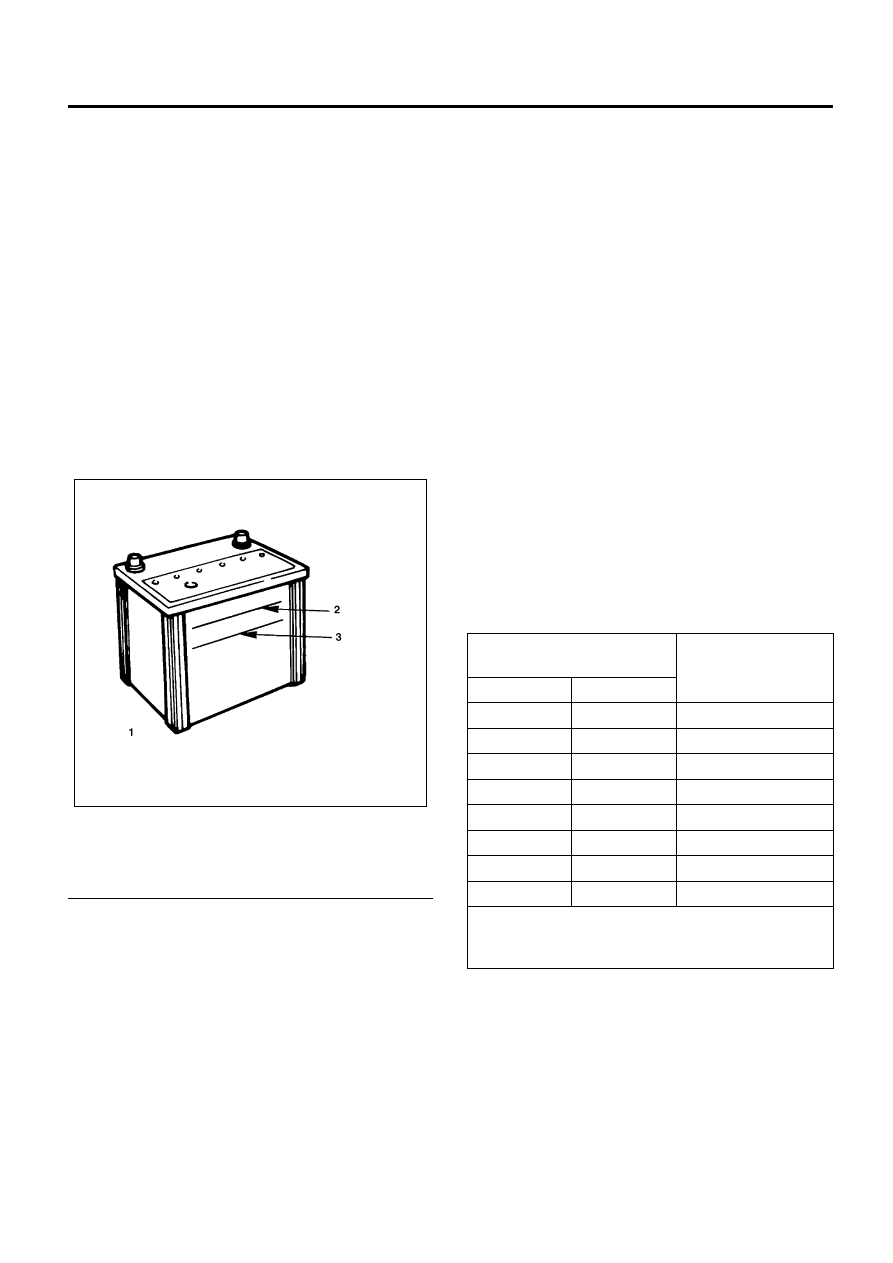

Fluid Level Check

The fluid level should be between the upper level line

and lower level line on side of the battery.

Legend

1. Battery

2. Upper Level

3. Lower Level

Voltage Check

1. Put voltmeter test leads to battery terminals.

a. VOLTAGE IS 12.4V OR ABOVE - Go to “Load

Test”.

b. VOLTAGE IS UNDER 12.4V - Go to procedure

2 below.

2. Determine fast charge amperage from

specification.

Fast charge battery for 30 minutes at amperage

rate no higher than specified value.

Take voltage and amperage readings after charge.

a. VOLTAGE IS ABOVE 16V AT BELOW 1/3 OF

AMPERAGE RATE - Replace battery.

b. VOLTAGE IS ABOVE 16V AT ABOVE 1/3 OF

AMPERAGE RATE - Drop charging voltage to

15V and charge for 10 — 15 hours.

Then go to “Load test”.

c. VOLTAGE IS BETWEEN 12V AND 16V

- Continue charging at the same rate for an

additional 3-1/2 hours. Then go to “Load test”.

d. VOLTAGE IS BELOW 12V - Replace battery.

Load Test

1. Connect a voltmeter and a battery load tester

across the battery terminals.

2. Apply 300 ampere load for 15 seconds to remove

surface charge from the battery.

Remove load.

3. Wait 15 seconds to let battery recover. Then apply

specified load from specifications (See Main Data

and Specifications in this section).

Read voltage after 15 seconds, then remove load.

1) VOLTAGE DOES NOT DROP BELOW THE

MINIMUM LISTED IN FOLLOWING TABLE

- The battery is good and should be returned to

service.

2) VOLTAGE IS LESS THAN MINIMUM LISTED

- Replace battery.

On-vehicle Service

Battery Charging

Observe the following safety precautions when charging

the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery.

In this case, the battery must be replaced.

N6A0983E

ESTIMATED

TEMPERATURE

MINIMUM VOLTAGE

°F

°C

70

21

9.6

60

16

9.5

50

10

9.4

40

4

9.3

30

− 1

9.1

20

− 7

8.9

10

− 12

8.7

0

− 18

8.5

The battery temperature must be estimated by feel

and by the temperature the battery has been

exposed to for the preceding few hours.