Isuzu N-Series. Service manual - part 529

6C-24 Fuel System

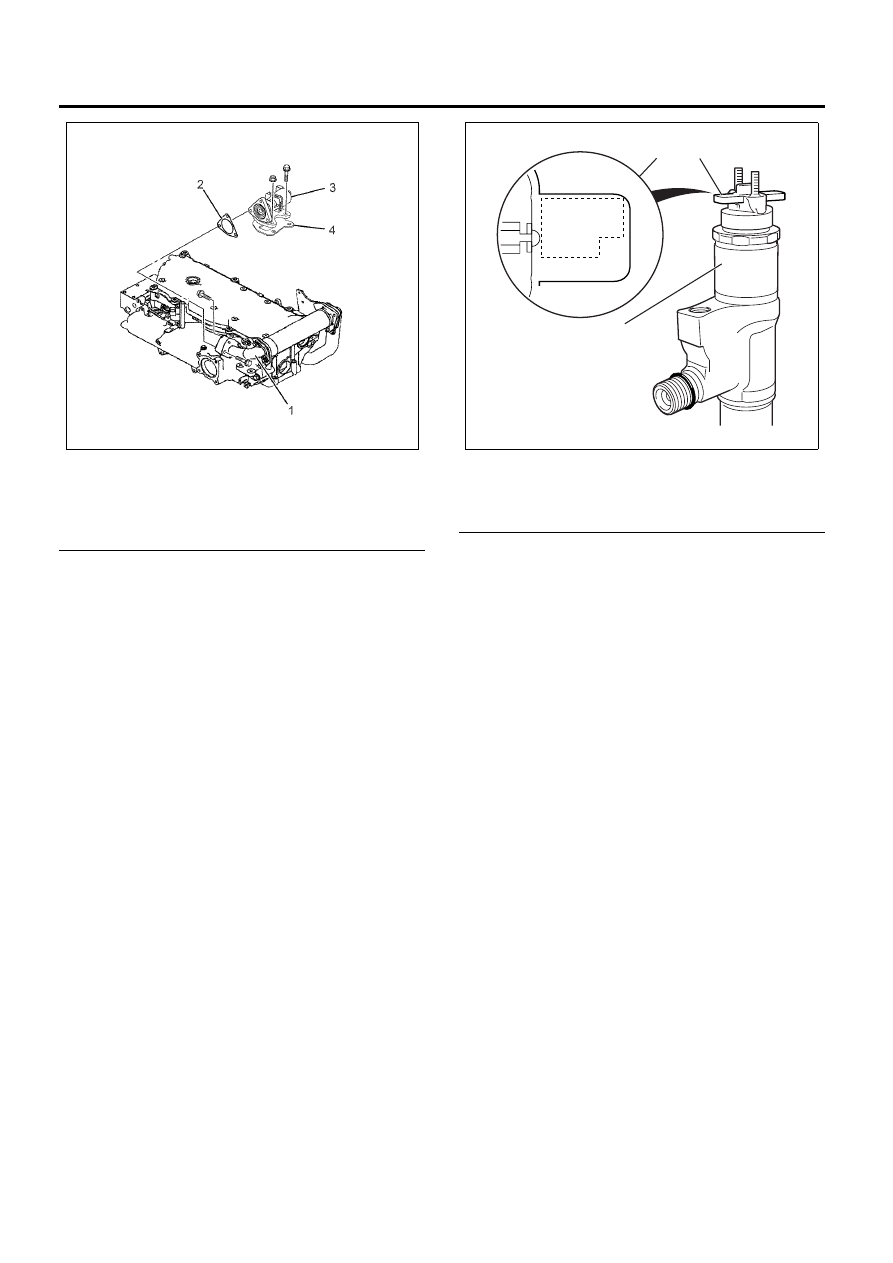

Legend

1. EGR Adapter

2. EGR Valve Gasket

3. EGR Valve

4. EGR Valve Gasket

20. Attach the engine harness connectors. Each

composite connector should make a loud click

when it is securely attached.

Fuel Injector ID Code Data Programming Procedure

1. Install the Tech 2.

2. Turn ON the ignition, with the engine OFF.

3. Select Diagnostics > appropriate vehicle

identification > 4HK1 (Common Rail) >

Programming > Injector ID Code > ID Code

Registration.

4. Select replaced cylinder and press Change. Input

22 figures. Then, input in order from the left edge

of upper sequence to the right sequence. The

correct order for the fuel injector ID code for the

following illustration is as follows:

56 00 D1 CA 00 00 EC 00 23 14 21

Important:

The number of places required for input is 22 figures

except last 2 figures.

Legend

1. Fuel Injector ID Plate

2. Fuel Injector ID Code

3. Fuel Injector

5. After complete the registration, turn OFF the

ignition for 30 second.

6. Turn ON the ignition.

7. Select Diagnostics > appropriate vehicle

identification > 4HK1 (Common Rail) >

Programming > Injector ID Code > Injector ID

Code. At this point, all registered fuel injector ID

code data can be verified. Compare the ID code

values registered into the ECM and each fuel

injector including the last 2 figures. If the registered

ID code is incorrect, go back to Step 4 ID Code

Registration.

8. Start the engine and let idle.

9. Inspect for a proper engine running condition and

for no DTC’s. Refer to the Diagnostic System

Check-Engine Controls if needed.

Notice:

After replacement of the fuel injector, perform the

following procedure.

All fuel injectors are replaced:

Remove the fuel injector ID code label on the cylinder

head cover.

Any fuel injector(s) is replaced:

Blackout the replaced cylinder fuel injector ID code on

the cylinder head cover with a marking pen or

equivalent.

N6A6371E

D1CA

EC00

2100

B7

5600

0000

2314

0000

1

2

3

N6A6525E