Isuzu N-Series. Service manual - part 328

6A-54 ENGINE MECHANICAL

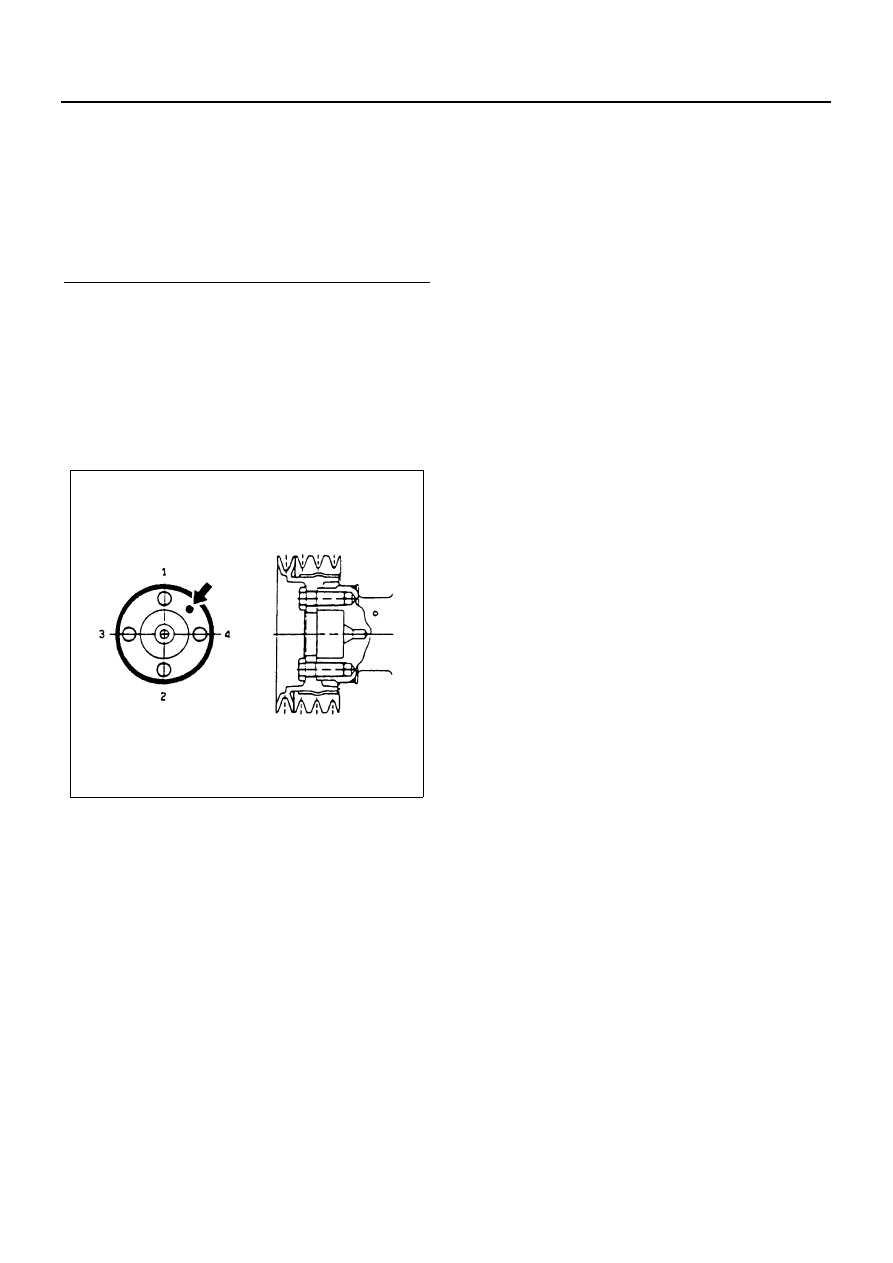

30. Crankshaft Damper Pulley

1) Apply a coat of engine oil to the threads of the

bolts.

2) Align the damper pulley with the crankshaft

knock pin and tighten the bolts to the specified

torque in numerical order.

Tighten:

Damper pulley bolt to 200 N

⋅m (20.4 kg⋅m / 147 lb⋅ft)

31. Generator Bracket

32. Fan Belt Adjust Plate

33. Injection Pump Assembly

34. Engine Foot

35. Generator

36. Fan Belt

37. Fan Belt Adjustment

38. Vacuum Pump Rubber Hose

39. Vacuum Pump Oil Pipe

40. Oil Filter Assembly

41. Oil Pipe

42. Engine Control Lever Assembly

43. Engine Control Wire

44. Driven Plate

45. Clutch Pressure Plate Assembly

46. Cylinder Head Gasket

Above works refer to “CYLINDER BLOCK” section

in this manual.

47. Cylinder Head Assembly

Above works refer to “CYLINDER HEAD” section

in this manual.

Legend

1. Oil seal

2. Adapter

3. Ring

4. Adapter bolt

5. Sleeve

6. Washer (5 mm (0.20 in))

7. Center bolt

N6A0250E