Haima S5. Chassis System. Instruction - part 7

Brake system 2F-42

1) For the faults of wheel speed sensor signals, after removing the faults, be sure to start the vehicle and

increase its speed up to about 15km/h, thus ABS warning lamp can go out.

2) Don’t measure the supply voltage from the wheel speed sensor to ECU. Once the open circuit of

wheel speed sensor exists, ECU will stop its power supply automatically, until its power supply is

recovered after the next ignition self-check.

4.7 ECU faults

Fault codes: C100004; C101008

Fault setting conditions

(1) ECU supply fault.

(2) Damages of ECU.

Possible fault causes

ECU faults

Diagnostic steps

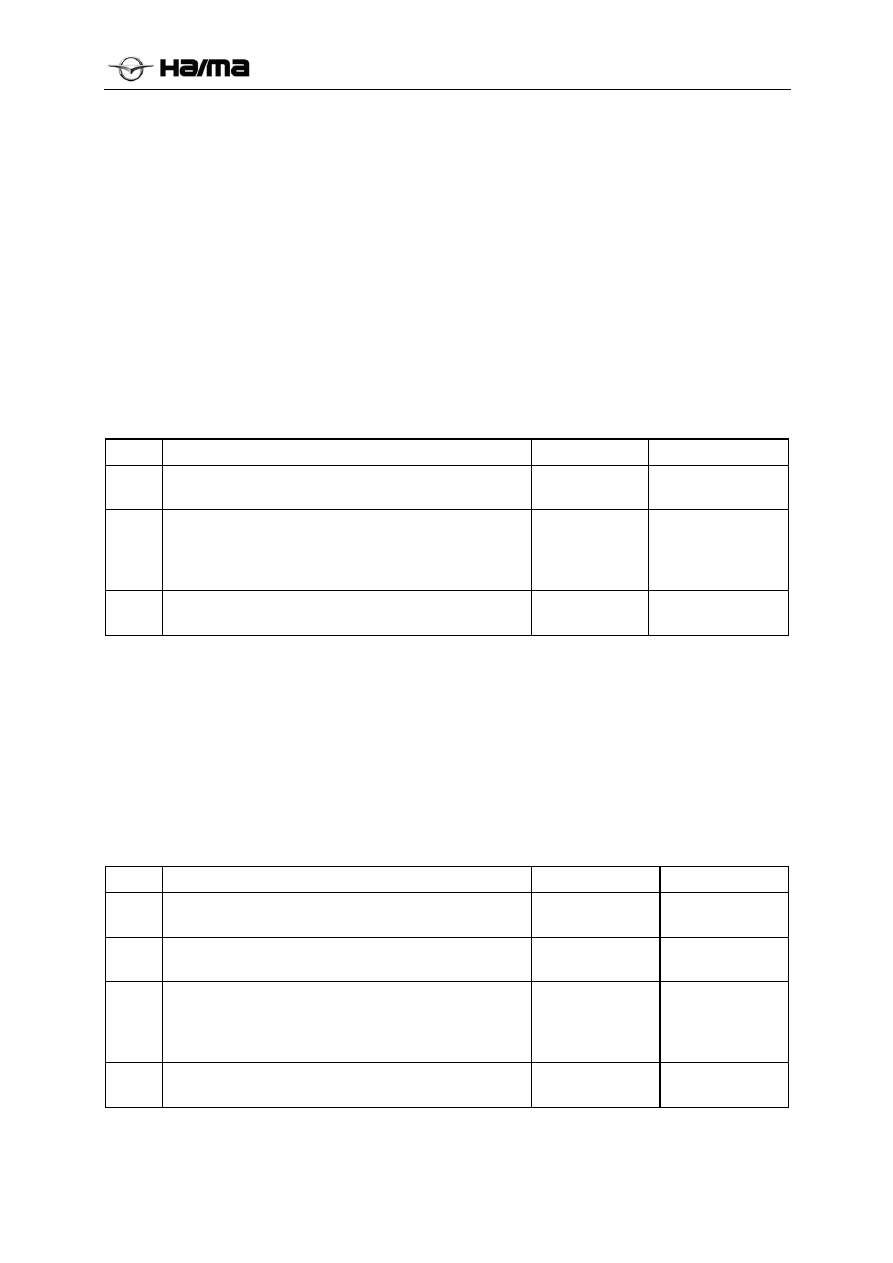

Step Operation

Yes

No

1

Is the initial check performed?

Perform Step 2.

Perform the initial

check.

2

Cross validation of ABS (for its detailed steps, refer to

Section “Removal and Installation”). In case of

confirming the damages of ABS, replace ABS. Is the

fault removed?

Perform Step 3.

-

3

Re-diagnose it, and confirm whether the fault is

regenerated?

-

Completion of

diagnostic work

4.8 Unreasonable control of ABS

Fault codes:C006B06

Fault setting conditions

ABS receives the command of continual operation (above 1 minute).

Possible fault causes

(1) Continual braking of ice.

(2) Overlarge

wheel

speed difference.

Diagnostic steps

Step Operation

Yes

No

1

Is the initial check performed?

Perform Step 2.

Perform the

initial check.

2

Check the wheel speed sensor and gear ring. Are the

faults removed?

Perform Step 4.

Perform Step 3.

3

Cross validation of ABS (for its detailed steps, refer to

Section “Removal and Installation”). In case of

confirming the damages of ECU, replace ABS. Is the

fault removed?

Perform Step 4.

-

4

Re-diagnose it, and confirm whether the fault is

regenerated?

-

Completion of

diagnostic work