Ford Orion. Manual - part 54

11 Disconnect the multi-plug from the rear of

the module, and remove the module from the

vehicle.

Warning: Position the air bag

module in a safe place, with the

mechanism facing downwards as

a precaution against accidental

operation.

12 Undo the four screws, and remove the

steering column lower shroud.

13 Undo the screws and withdraw the

detachable lower facia panel from beneath

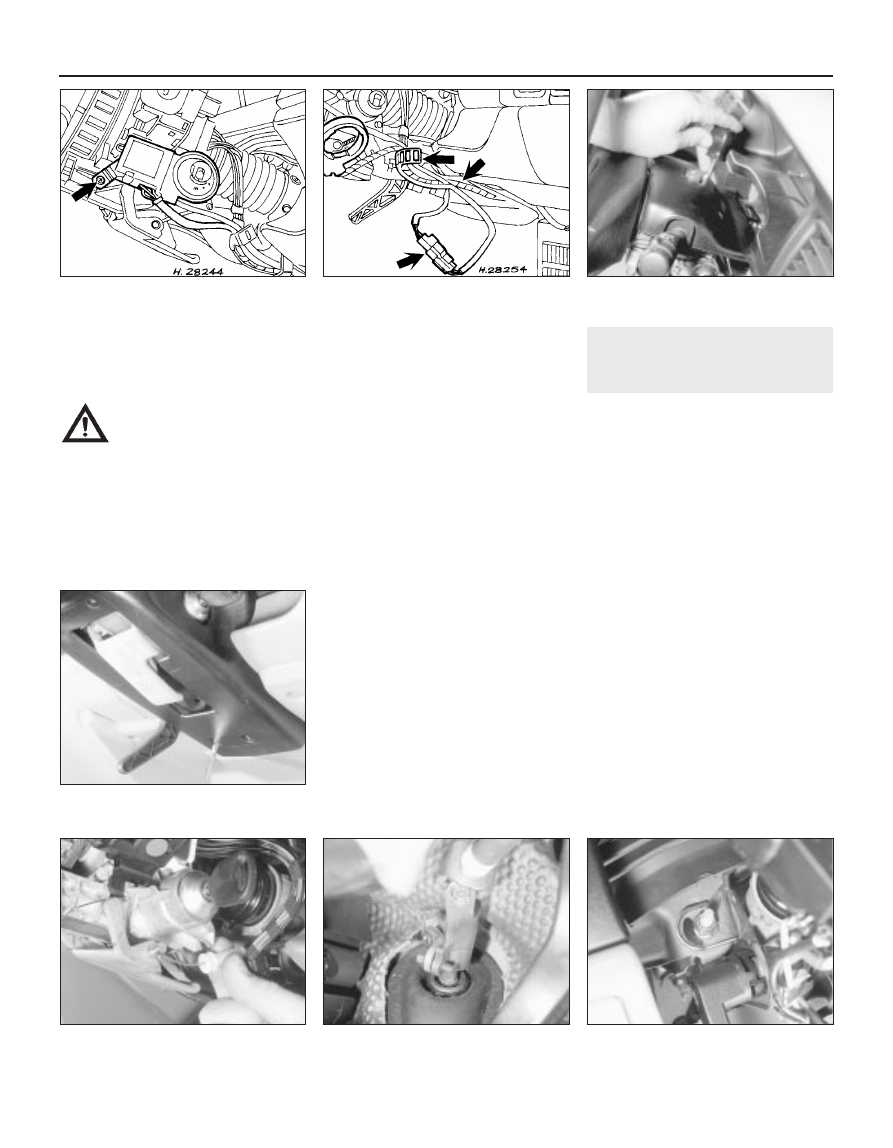

the steering column (see illustration).

14 Where applicable, undo the single screw

and withdraw the Passive Anti-Theft

System (PATS) transceiver from the

iignition switch/steering lock barrel (see

illustration).

15 Release the steering column wiring

harness from the retaining clips, and

disconnect the air bag module wiring harness

multi-plug (see illustration).

16 Turn the steering wheel so that the

roadwheels are in the straightahead position,

then remove the ignition key to lock the

steering.

17 Unscrew the retaining bolt from the centre

of the steering wheel, then insert the ignition

key and turn it to position “I”. Grip the steering

wheel each side, then pull and withdraw it

from the column shaft. If the wheel is reluctant

to budge, give it a sharp tap on the underside

of the spoke (as near to the hub as possible)

with the palm of your hand.

Refitting

All models

18 Refit in the reverse order of removal.

Ensure that the indicator stalk is set in its

central (off) position, to avoid damaging it with

the tag of the wheel as it is pushed down the

shaft. Make sure that the wheel is centralised,

as noted on removal. Turn the ignition key so

that it is in position “I” (steering unlocked).

Tighten the retaining bolt to the specified

torque setting.

21 Steering column -

removal and refitting

3

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

2 Remove the steering wheel as described in

the previous Section.

3 Remove the screws and withdraw the

steering column upper and lower shrouds

(see illustrations).

4 Remove the multi-function switch assembly

from the column, with reference to Chapter

12.

5 Disconnect the ignition switch multi-plug,

and release the wiring from the wiring loom

guide.

6 Detach the bonnet release cable from the

lever, then remove the lever from the column

(see illustration).

7 Unscrew and remove the clamp bolt

securing the steering column to the pinion

shaft (see illustration).

8 Loosen off the column lower retaining nuts,

then unscrew and remove the upper retaining

nuts (see illustration). Remove the steering

column from the vehicle.

Refitting

9 Refitting is a reversal of the removal

procedure, but note the following:

10•14 Suspension and steering systems

21.8 Steering column upper retaining nut

(on the left-hand side of the column)

21.7 Steering column-to-pinion shaft

coupling and clamp bolt

21.6 Detach the bonnet release cable from

the lever

21.3B . . . and lower steering column

shrouds

21.3A Remove the upper . . .

20.15 Release the steering column wiring

harness and multi-plug as indicated

20.14 Undo the screw (arrowed) and

withdraw the Passive Anti-Theft System

(PATS) transceiver from the ignition

switch/steering lock barrel