Ford Orion. Manual - part 52

2 Open and support the bonnet. Prise free

the protective cap from the strut upper

retaining nut, then loosen off, but do not

remove, the central retaining nut. As the nut is

loosened off, hold the strut piston rod with an

Allen key to prevent the rod from turning as

the nut is loosened (see illustrations).

3 Detach the front brake hose from the

support bracket on the strut.

4 Where applicable, unbolt and detach the

anti-roll bar link rod from the suspension strut.

5 Unscrew and remove the strut-to-spindle

carrier clamp bolt.

6 Note the direction of fitting, then unscrew

and remove the lower arm balljoint-to-spindle

carrier clamp bolt. Prise the joint open using a

large flat-bladed tool, and detach the balljoint

from the spindle carrier. Take care not to

damage the balljoint seal during the

separation procedures.

7 Prise open the spindle carrier-to-strut joint,

and separate the carrier from the strut. Tap

the carrier downwards using a soft-faced

hammer to release it from the strut if

necessary.

8 Support the weight of the strut underneath,

and unscrew the two nuts securing it to the

turret at the top. Lower the strut and remove it

from the vehicle.

Refitting

9 Refitting is a reversal of removal. Tighten all

the retaining bolts to the specified torque.

When reconnecting the suspension lower arm

balljoint to the spindle carrier, ensure that the

clamp bolt is fully engaged in the locating

groove, and prevent the bolt from turning as

the nut is tightened.

7

Front suspension strut -

dismantling, examination and

reassembly

4

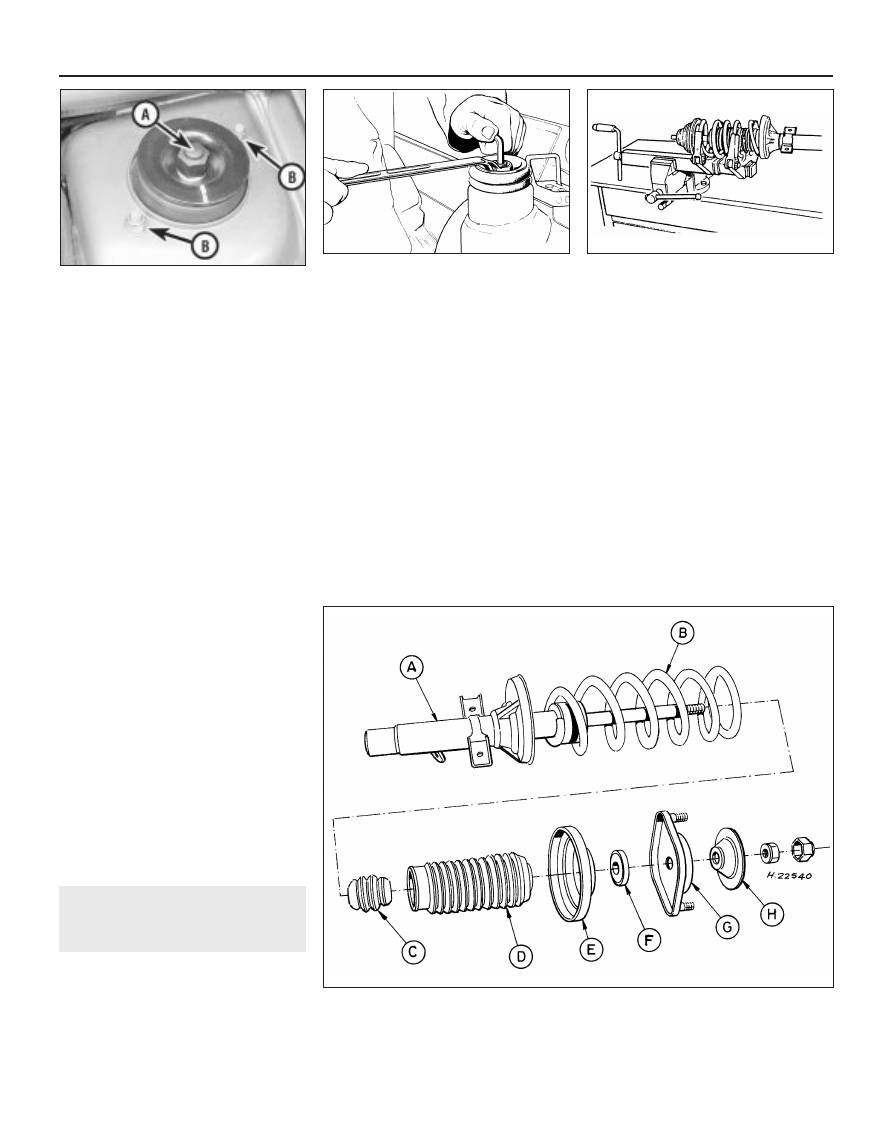

Note: Before attempting to dismantle the front

suspension strut, a tool to hold the coil spring

in compression must be obtained. The Ford

tool is shown in the accompanying

illustrations, however careful use of

conventional coil spring compressors will

prove satisfactory.

Dismantling

1 With the strut removed from the vehicle,

clean away all external dirt, then mount it

upright in a vice.

2 Fit the spring compressor tool (ensuring

that it is fully engaged) and compress the coil

spring until all tension is relieved from the

upper mounting (see illustration).

3 Hold the strut piston with an Allen key, and

unscrew the nut with a ring spanner.

4 Withdraw the cup, retainer (top mounting),

the bearing and upper spring seat, followed

by the gaiter and the bump stop (see

illustration).

5 The suspension strut and coil spring can now

be separated. If a new coil spring or strut is to

be fitted, the original coil spring must be

released from the compressor. If it is to be re-

used, the coil spring can be left in compression.

Examination

6 With the strut assembly now completely

dismantled, examine all the components for

wear, damage or deformation, and check the

bearing for smoothness of operation. Renew

any of the components as necessary.

7 Examine the strut for signs of fluid leakage.

Check the strut piston for signs of pitting

along its entire length, and check the strut

body for signs of damage or elongation of the

mounting bolt holes. Test the operation of the

strut, holding it in an upright position, by

moving the piston through a full stroke, and

then through short strokes of 50 to 100 mm.

In both cases, the resistance felt should be

smooth and continuous. If the resistance is

jerky, or uneven, or if there is any visible sign

of wear or damage to the strut, renewal is

necessary.

10•6 Suspension and steering systems

7.4 Front suspension strut components

7.2 Ford special tool in use to compress

the front suspension strut coil spring

6.2B Method to use when loosening off

the strut upper mounting

6.2A Front suspension strut upper

mounting showing the protective cap over

retaining nut (A) and the strut-to-body

mounting nuts (B)

A

Strut

B Spring

C Bump stop

D Gaiter

E

Upper spring seat

F

Bearing

G Top mounting retainer

H Top mounting cup