Snowmobile Polaris Two Stroke (2007 year). Instruction - part 36

5.37

ENGINE

5

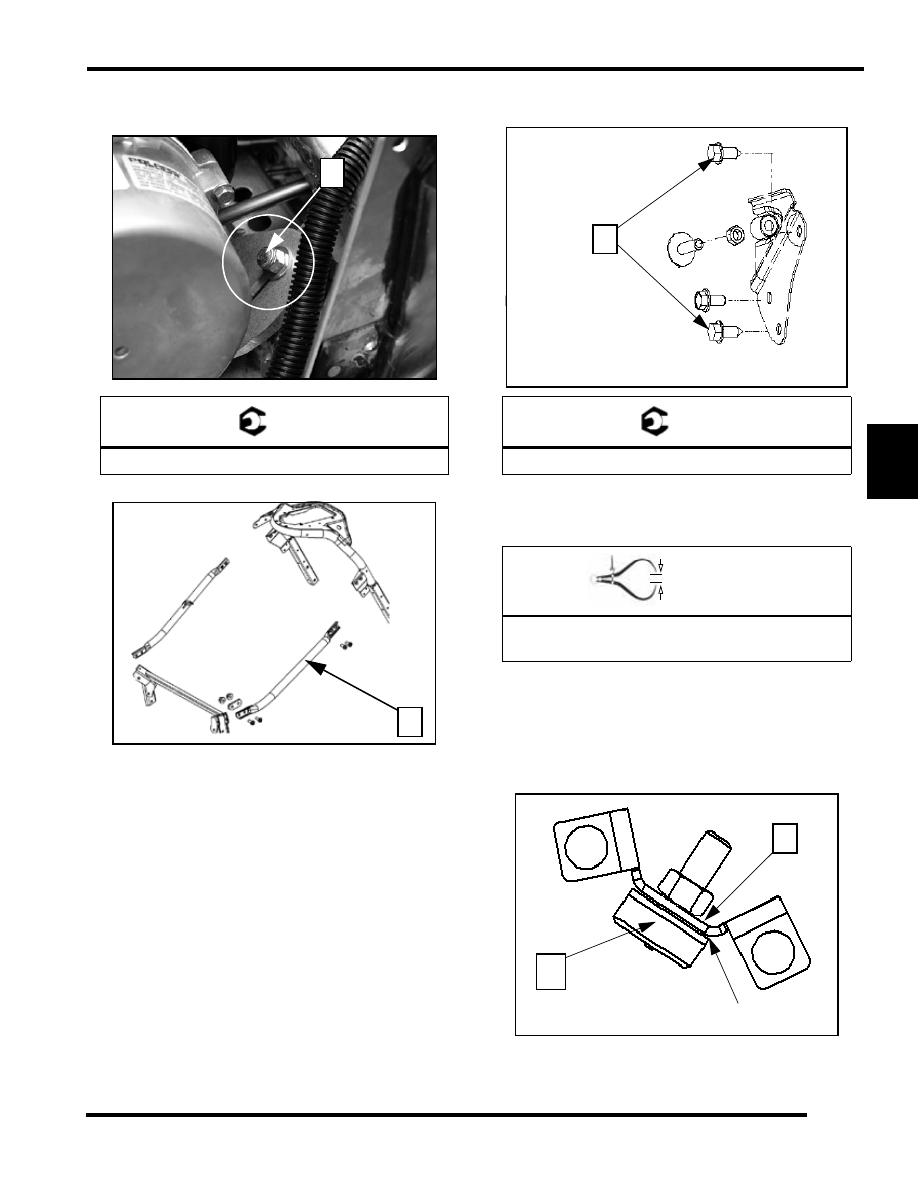

21. Place the engine mount washers and fasteners (8) onto the

engine mount studs. Torque to specification.

22. Install the right hand chassis brace (9).

23. Apply Blue Loctite™ to the rear fasteners (10), install all

the rear torque stop fasteners and torque to specification.

24. Adjust the rear torque stop so that you have a clearance of

.010”-.030” (.25-.75mm) from the face of the torque stop

to the surface of the engine.

NOTE: If a new torque stop is installed, install it so

that the nub is touching the engine. This nub is .030"

(.75mm) long.

25. Adjust the engine isolator limiter (11) so that the stop is

bottomed out on the brace (12). See “Engine Isolator

Limiter Setting” on page 3.22.

= T

Engine Mount Fasteners: 28 ft.lb (37.9 N-m)

8

9

= T

Rear Torque Stop Fasteners: 28 ft.lb (37.9 N-m)

= In. / mm.

Rear Torque Stop Clearance:

.010"-.030" (.25-.75mm)

10

11

Torque Stop touching base

12