Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 821

Greasing Bonded Rubber Bushing:

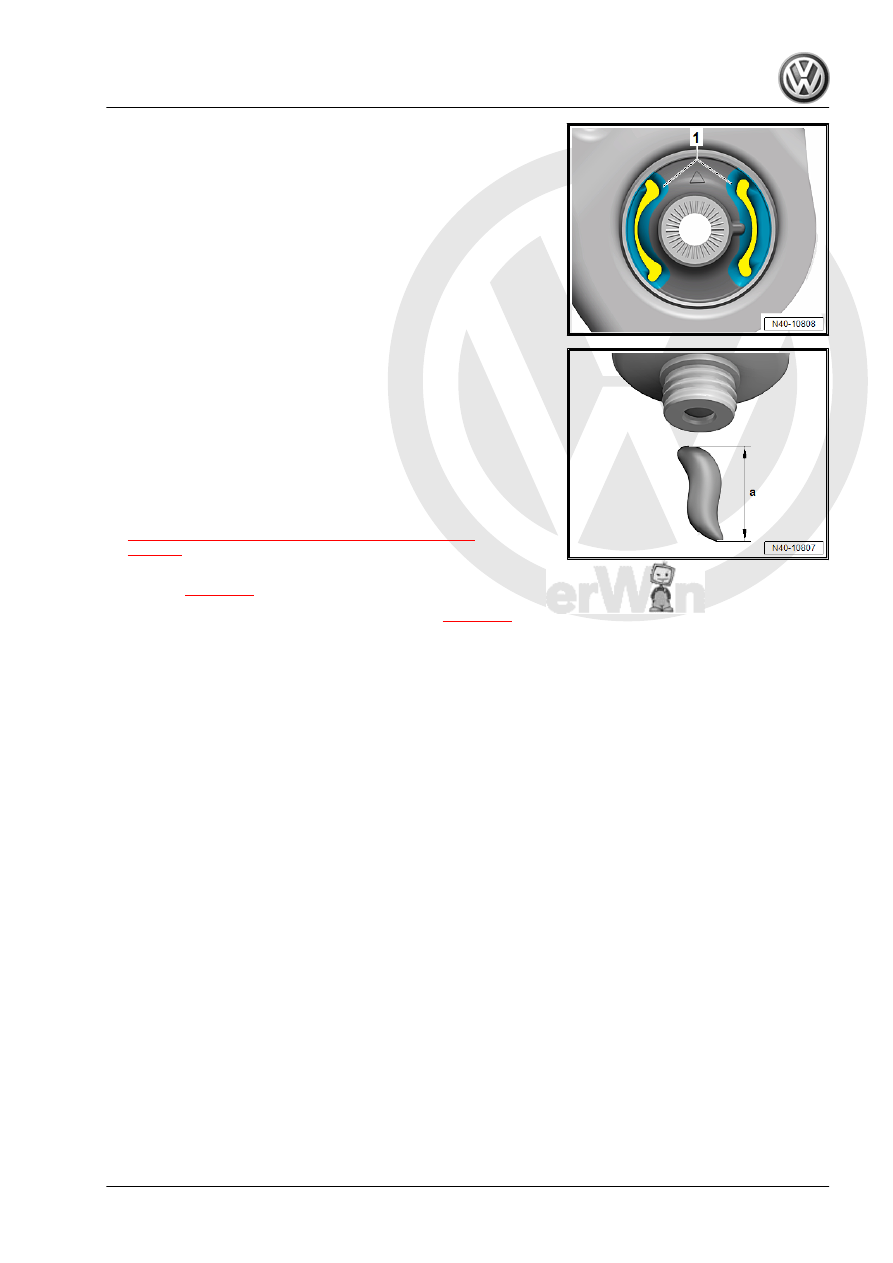

The kidney-shaped area -1- of the bonded rubber bushing must

be lubricated.

– To do so, apply grease in the kidney-shaped area -1- starting

from the top working outward.

– Use the Grease - N.052.150.00.- .

– The required quantity of grease together for both sides should

be approximately 1 cm -dimension a- as shown.

• Half of the grease quantity (approximately 0.5 cm) must be

applied per kidney-shaped area.

– The grease quantity must be applied on the top using a com‐

mercially available brush.

– The contact surfaces to the control arm must not come in con‐

tact with grease.

– Install the control arm

⇒ “4.2 Lower Control Arm, Removing and Installing”,

♦ Vehicles with manual transmission, DSG transmission 0CW.

♦ Vehicles with DSG Transmission 0D9. Refer to