Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 809

♦ Engine and Gearbox Jack - VAS6931-

♦ Locating Pins - T10486/1-

♦ Vehicle Diagnostic Tester

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Bolt - Universal Joint to Steering Gear

♦ Bolts - Pendulum Support to Transmission

♦ Nut - Coupling Rod to Stabilizer Bar

Removing

– Turn the steering wheel to the straight-ahead position and re‐

move the ignition key so that the steering wheel lock engages.

Vehicle with “Keyless Access” Keyless Locking and Starting Sys‐

tem

– Switch the ignition off and open the driver door so the steering

wheel lock locks.

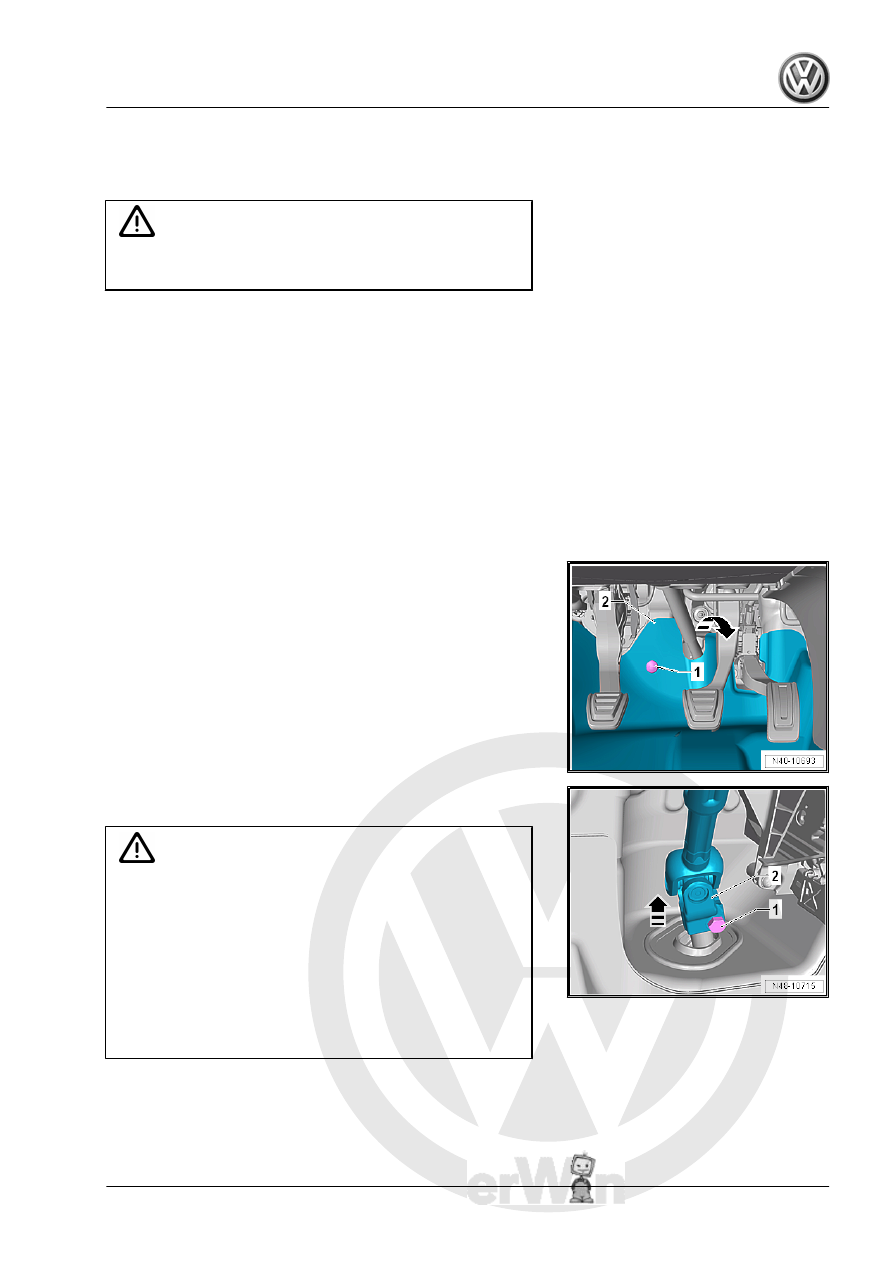

– Remove the bolt -1- and fold the footwell trim panel -2- in di‐

rection of -arrow- into the vehicle interior.

– Remove the bolt -1- from the universal joint -2-. Then remove

the universal joint in direction of -arrow-.

Caution

If the universal joint is separated from the steering gear, the

following work cannot be performed:

♦ Connect the battery.

♦ Switch on the ignition.

♦ Turning the steering gear

♦ Turning the steering column

These points must be observed, because otherwise it can

cause irreparable damage.

– Remove the lower noise insulation. Refer to ⇒ Body Exterior;

Rep. Gr. 66 ; Noise Insulation; Overview - Noise Insulation .