Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 657

3.2

Crankshaft Dimensions

(Dimensions in mm)

Reconditioning

Dimension

1)

Crankshaft Bearing

Pin Diameter

Connecting Rod

Bearing Pin Diame‐

ter

Basic dimension

58.00

47.80

1)

The preparation of worn crankshafts is not provided.

3.3

Main Bearing Shells Allocation

The bearing shells are allocated to the cylinder block with the

correct thickness at the factory. Colored spots serve to identify

the bearing thicknesses.

The code letters on the lower contact surface or on the top of the

cylinder block identify which bearing shell and where it must be

mounted on the cylinder block (upper bearing shell).

The code letters on the crankshaft identify which bearing shells

and where they must be installed in the bearing cover (lower

bearing shell).

The first letter is for bearing cover one, the second for bearing

cover two, etc.

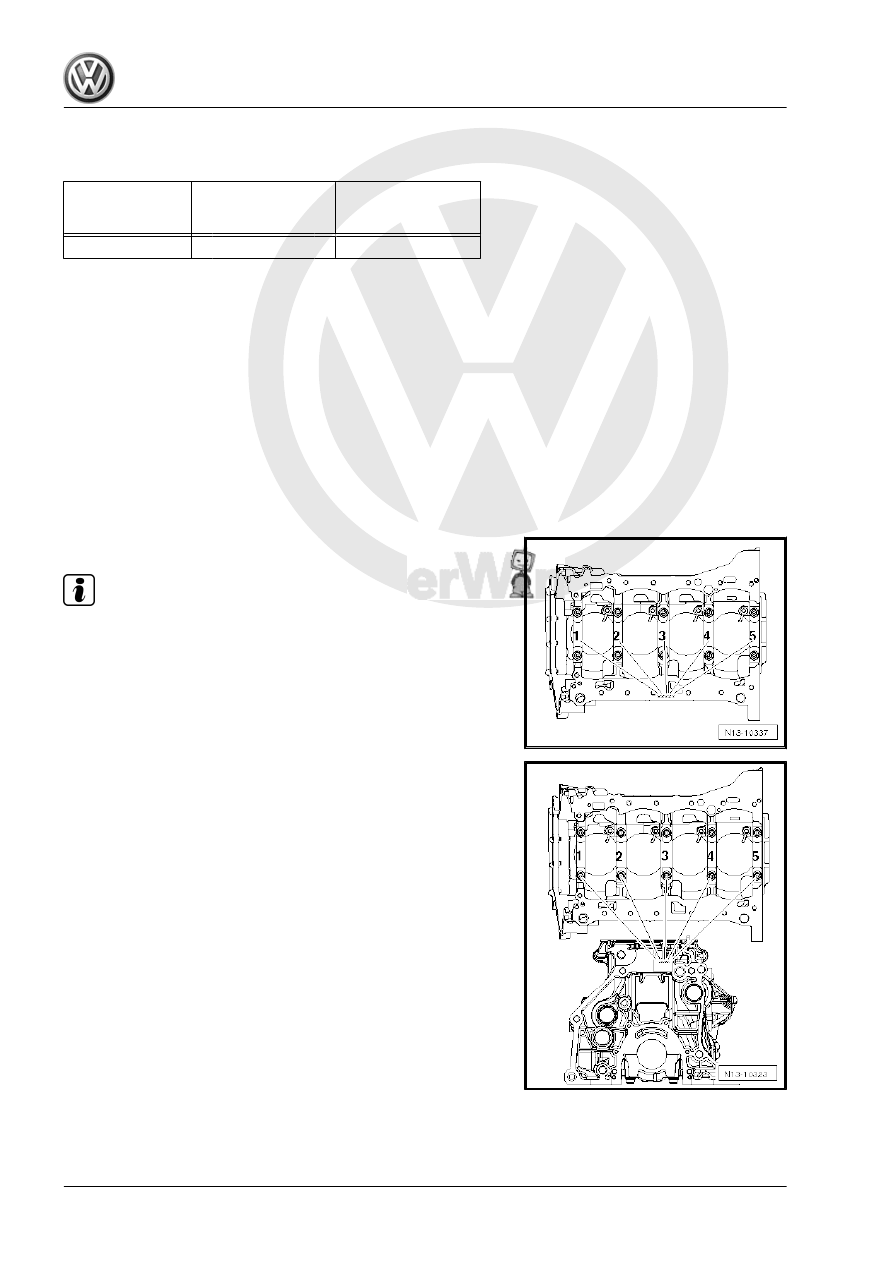

Cylinder Block Bearing Shell Identification:

Note

The cylinder block identification may be located either on the oil

pan sealing surface or on the top (transmission side) of the cyl‐

inder block.

The identification on the cylinder block is for the upper bearing

shell.

– Write down the letters and then use the table to find the color

identification.