Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 656

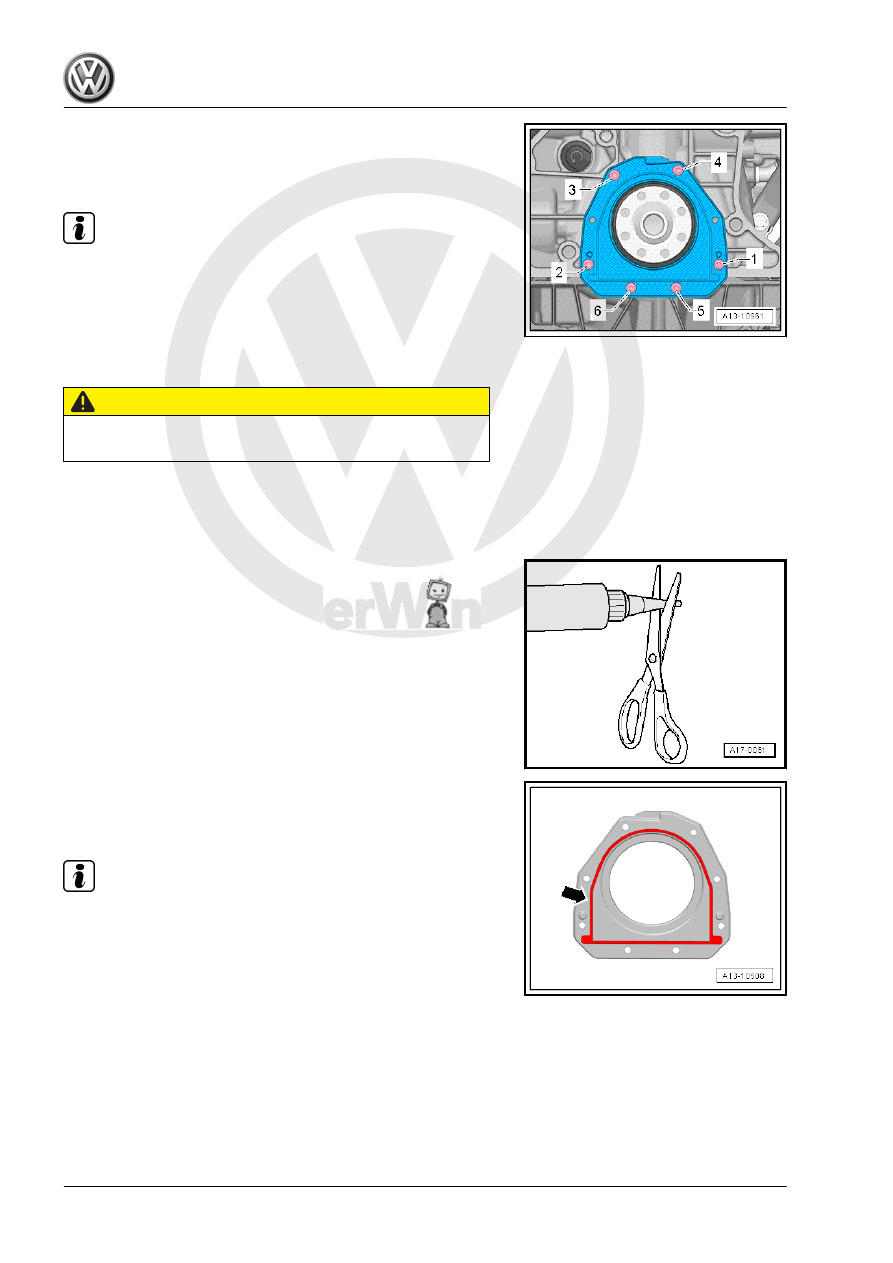

– Remove the bolts -1 through 6-.

– Remove sealing flange.

Installing

Note

♦

Be sure to check the expiration date of the silicone sealant.

♦

The sealing flange must be installed within 5 minutes after ap‐

plication of Silicone Sealant.

♦

To prevent contamination of the lubricating system with seal‐

ant residue, place a clean cloth over the open components of

the oil pan.

CAUTION

Risk of injuring the eyes from sealant residue.

– Wear protective eyewear.

– Remove remaining sealant on the cylinder head with a flat

blade scraper or with a rotating plastic brush.

– Sealing surfaces must be free of oil and grease.

– Cut the tube nozzle at the front marking (nozzle diameter: ap‐

proximately 2 mm).

– Apply silicone sealant as illustrated to the clean sealing sur‐

face of the sealing flange.

♦ Sealant bead thickness: 2 to 3 mm.

Note

♦

The sealing flange must be installed within five minutes after

application of silicon sealant.

♦

The sealant bead may not be thicker than specified, otherwise

excess sealant could enter the oil pan and clog the oil intake

tube.