Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 606

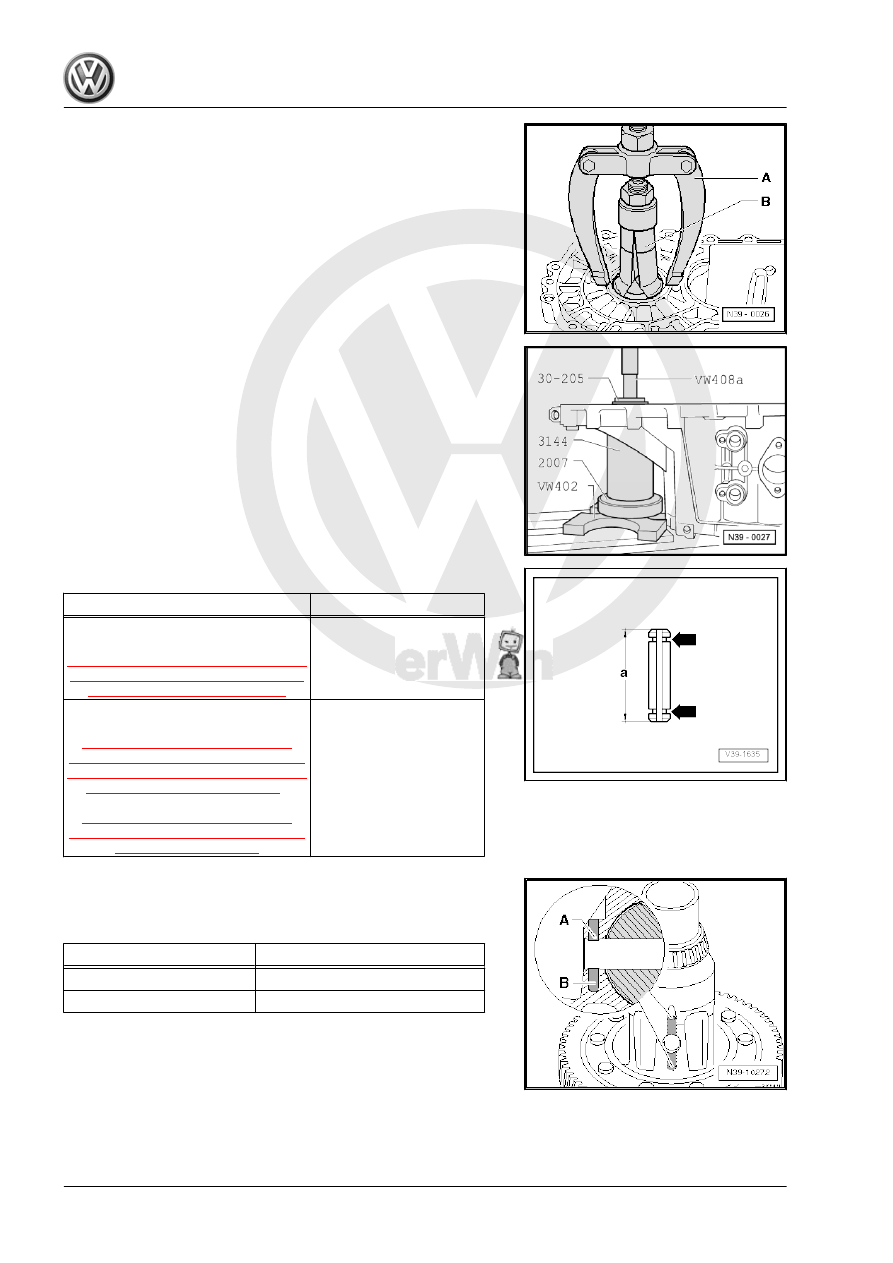

Removing the Outer Race/Tapered Roller Bearing from the

Transmission Housing

A - Counter Support , for example, Puller - Kukko Counterstay -

22/2-

B - Internal Puller 46 to 58 mm , for example, Puller - Kukko In‐

ternal - 46-56mm - 21/7-

Installing the Outer Race/Tapered Roller Bearing Into the Trans‐

mission Housing.

– Install the adjusting shim under the outer race.

– Support the transmission housing with the Bearing Installer -

Wheel Bearing - 3144- directly under the bearing mount.

Differentiating the Spring Pins

Dimension “a” mm

Identifying Feature

28.5 (short tension sleeve),

removing and installing. Refer to

⇒ Fig. ““Spring Pin with Surrounding

Groove (Short Spring Pin): Remov‐

ing and Installing”“ , page 193

Groove all the way

around -arrows-

36.0 (long spring pin),

removing. Refer to

⇒ Fig. ““Spring Pin Without Sur‐

rounding Groove (Long Spring Pin),

Removing: Press Out the Differential

installing. Refer to

⇒ Fig. ““Spring Pin Without Sur‐

rounding Groove (Long Spring Pin),

no surrounding groove

Allocation, Differential Housing

The hole in the differential housing was modified due to the longer

spring pin.

Hole

Spring Pin Length (mm)

-A-

28.5 (short spring pin)

-A- and -B-

36.0 (long spring pin)