Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 576

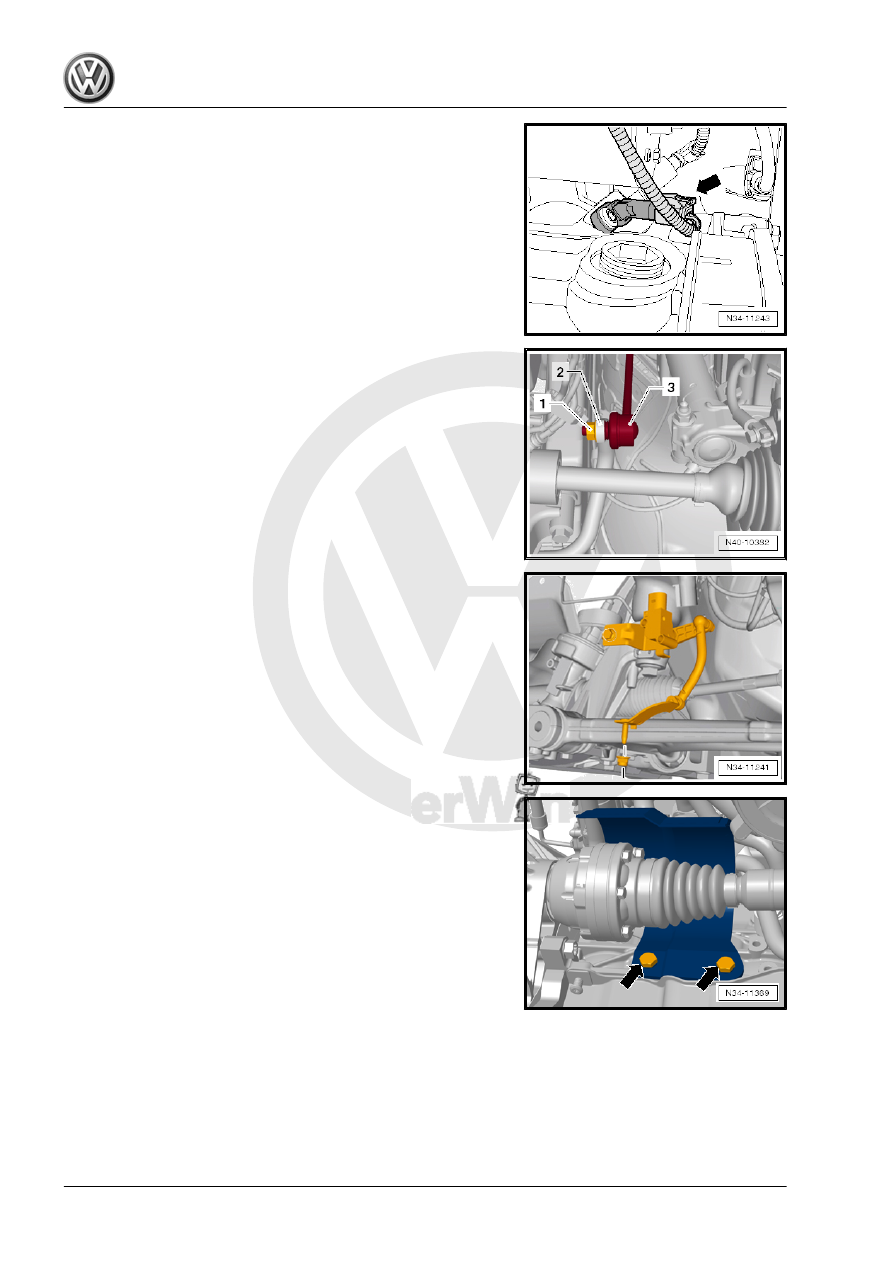

– Remove all wires from the transmission.

– Transmission on vehicles with Start/Stop System: disconnect

the connector -arrow- from the Transmission Neutral Position

Sensor - G701- .

– Remove the starter. Refer to ⇒ Electrical Equipment; Rep. Gr.

27 ; Starter; Starter, Removing and Installing .

– Remove the nuts -1- from both sides of the coupling rod -3-.

– Remove the coupling rod -3- from both sides of the stabilizer

bar -2-.

– If equipped, remove the Left Front Level Control System Sen‐

sor - G78- from the lower control arm. Refer to ⇒ Suspension,

Wheels, Steering; Rep. Gr. 43 ; Level Control System Sensor;

Overview - Front Level Control System Sensor .

– Remove the drive axle heat shield -arrows- (if equipped). Re‐

fer to ⇒ Suspension, Wheels, Steering; Rep. Gr. 40 ; Drive

Axle; Drive Axle Heat Shield, Removing and Installing .

– Remove the drive axles from the flange shafts and tie them up

as high as possible. Be careful not to damage the surface pro‐

tection. Refer to ⇒ Suspension, Wheels, Steering; Rep. Gr.

40 ; Drive Axle; Drive Axle, Removing and Installing .