Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 564

Continuation for All

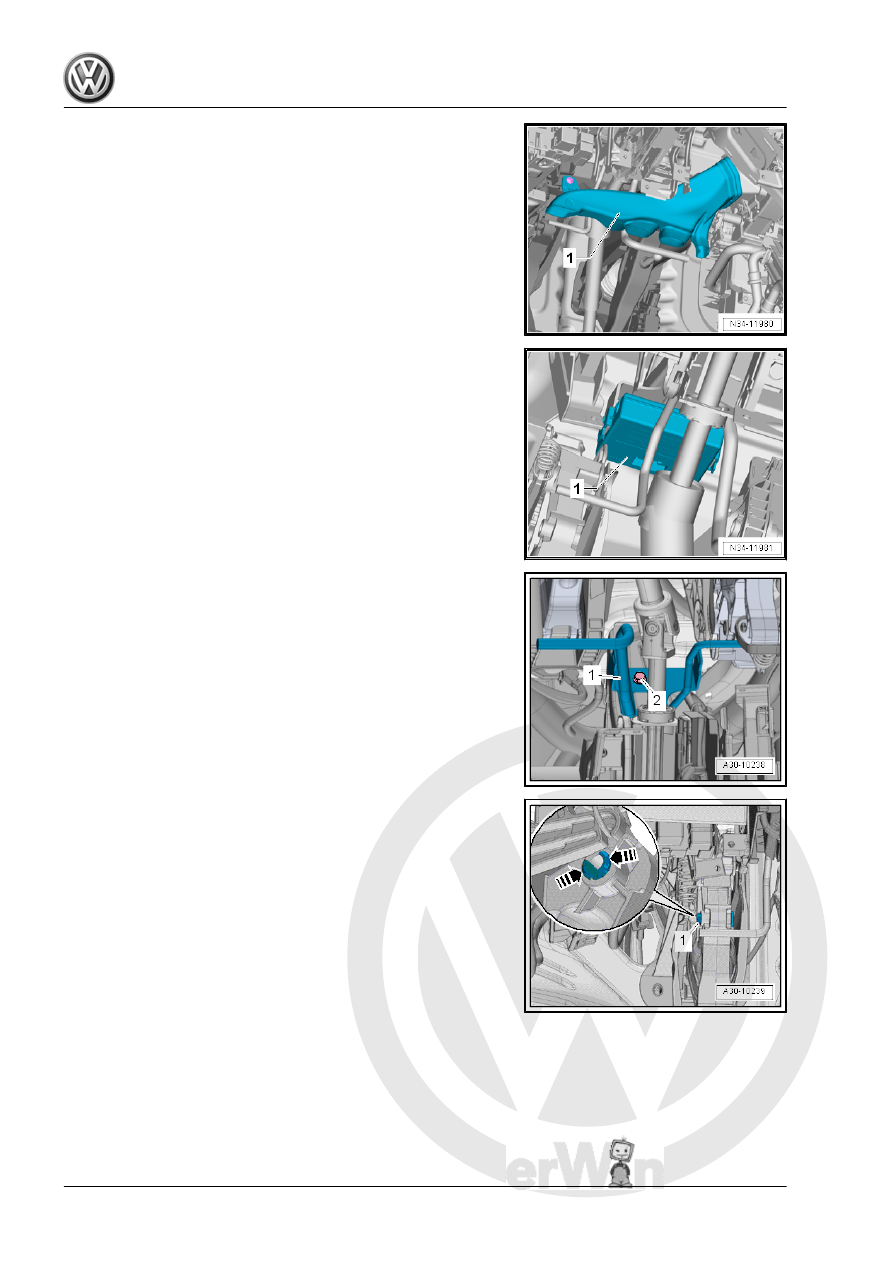

– Remove driver side footwell vent -1-. Refer to ⇒ Heating,

Ventilation and Air Conditioning; Rep. Gr. 87 ; Air Routing;

Driver Side Footwell Vent, Removing and Installing .

– Remove the Data Bus on Board Diagnostic Interface - J533-

-1- from the bracket. Refer to ⇒ Electrical Equipment; Rep.

Gr. 97 ; Control Modules; Component Location Overview -

Control Modules and push it aside.

– Remove bolt -2-, unclip the crash bolster -1- and push aside.

– Press the retainers together in direction of -arrows- and re‐

move the mounting pin -1- for the valve lifter/clutch master

cylinder to the right.