Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 562

❑ Seals/O-rings suitable for the line connection material. Refer to

⇒ Fig. ““Sealing Rings/O-Rings for Hose/Line Assembly or Pipe”“ , page 16

❑ Allocation. Refer to the Parts Catalog.

13 - Clamp

❑ The clamp must be removed in order to remove/install the hose/line assembly

14 - Clutch Slave Cylinder

❑ Removing and installing. Refer to

⇒ “1.11 Clutch Slave Cylinder, Removing and Installing”, page 30

.

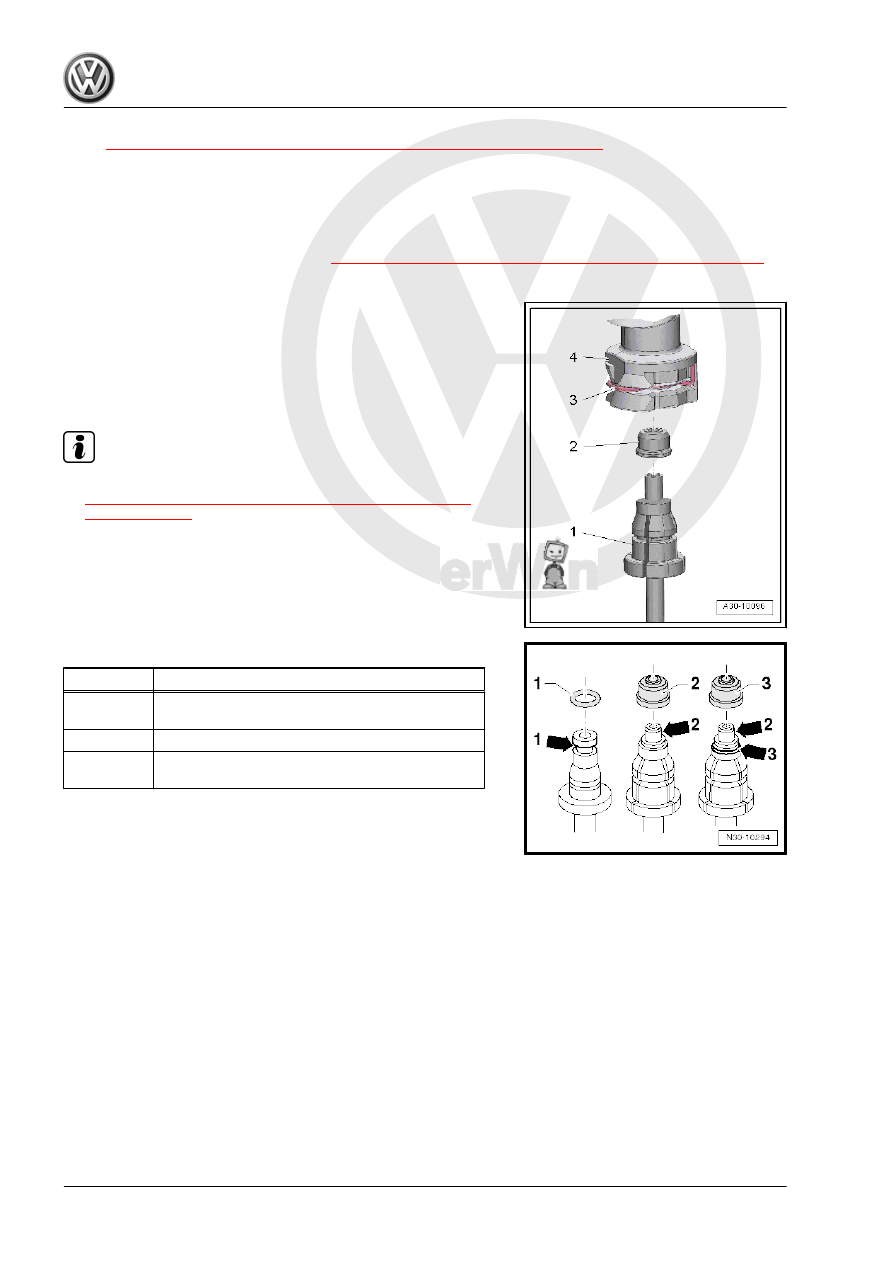

Disconnect and Connect Clutch Mechanism Wires

Separating

– Open the clip -3- with a screwdriver and remove the hose/line

assembly -1- from the connection -4-.

Connecting

Note

♦

An O-ring can also be installed instead of a seal -2-. Refer to

⇒ Fig. ““Sealing Rings/O-Rings for Hose/Line Assembly or

♦

Replace the damaged seal -2-.

– Press in the hose/line assembly -1- at the connection -4- until

the clip -3- engages audibly.

– Pull on the hose/line assembly to make sure it is secure.

Sealing Rings/O-Rings for Hose/Line Assembly or Pipe

Item

Line Connection Version

1

Line connection with a groove all the way around

-arrow 1-

2

Line connection with a shoulder -arrow 2-

3

Line connection with a shoulder -arrow 2- and with

a groove all the way around -arrow 3-

• The seal / O-ring must be installed in the groove -arrow 1- and

-arrow 3-.