Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 506

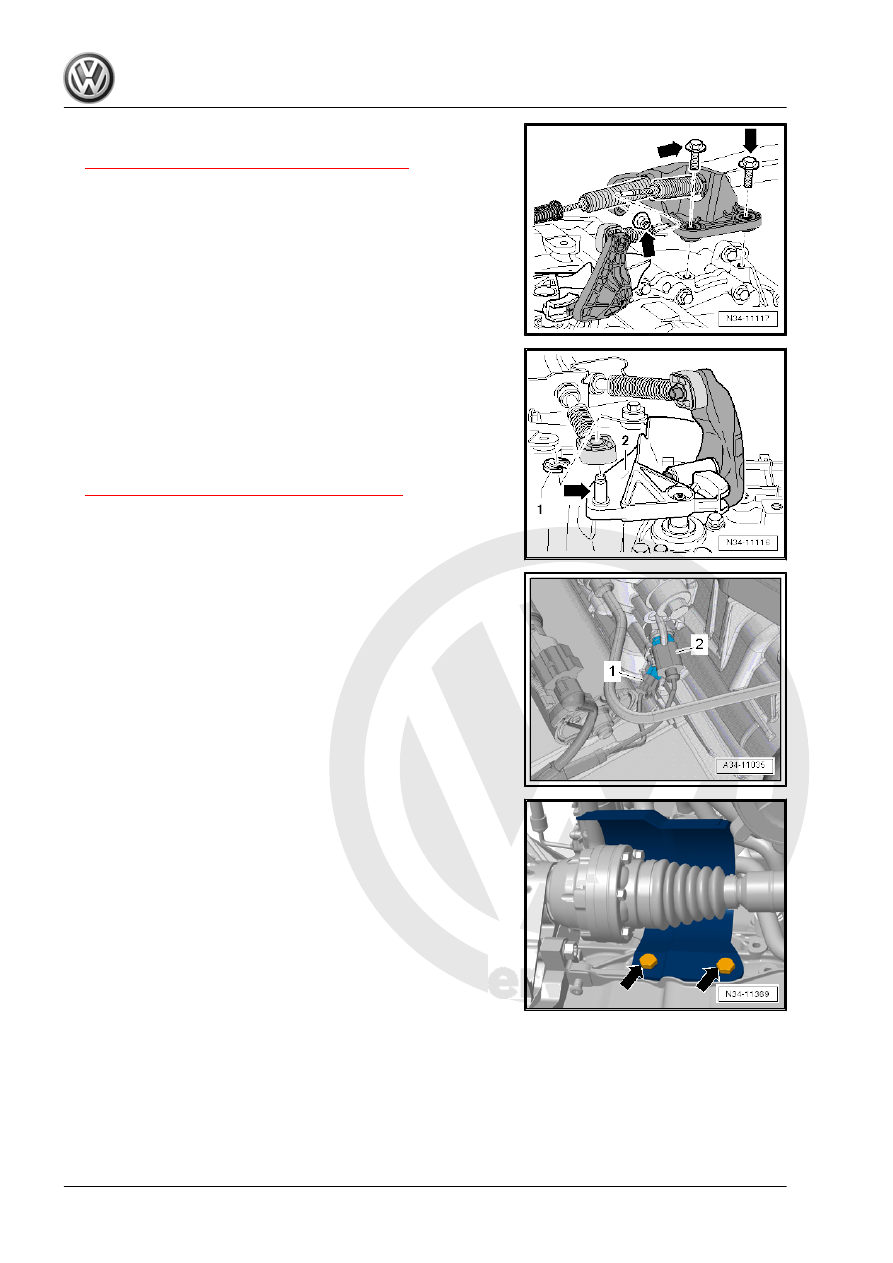

– Mount the cable bracket on the transmission and tighten the

bolts and nuts -arrows-. Refer to

⇒ “1.2 Overview - Selector Mechanism”, page 60

.

– Install the selector cable in the cable retainer.

– Apply a small amount of grease on the pins -arrow- for the shift

lever -2-.

Grease allocation. Refer to the Parts Catalog.

– Replace the lock washer -1- each time it is removed.

– Adjust the shift lever mechanism. Refer to

⇒ “1.6 Selector Mechanism, Adjusting”, page 71

.

– Install the starter. Refer to ⇒ Electrical Equipment; Rep. Gr.

27 ; Starter; Starter, Removing and Installing .

– Connect the front left connectors to the transmission:

1 - Transmission for vehicles with start/stop system: Transmis‐

sion Neutral Position Sensor - G701-

2 - Back-Up Lamp Switch - F4-

– Install the drive axles. Refer to ⇒ Suspension, Wheels, Steer‐

ing; Rep. Gr. 40 ; Drive Axle; Drive Axle, Removing and

Installing .

– Install the drive axle heat shield (if equipped). Refer to ⇒ Sus‐

pension, Wheels, Steering; Rep. Gr. 40 ; Drive Axle; Drive

Axle Heat Shield, Removing and Installing .

– Assemble the exhaust system. Refer to ⇒ Engine Mechanical,

Fuel Injection and Ignition; Rep. Gr. 26 ; Exhaust Pipes/Muf‐

flers; Overview - Muffler .

– Install the subframe together with pendulum support. Refer to

⇒ Engine Mechanical, Fuel Injection and Ignition; Rep. Gr.

10 ; Subframe Mount; Overview - Subframe Mount .