Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 505

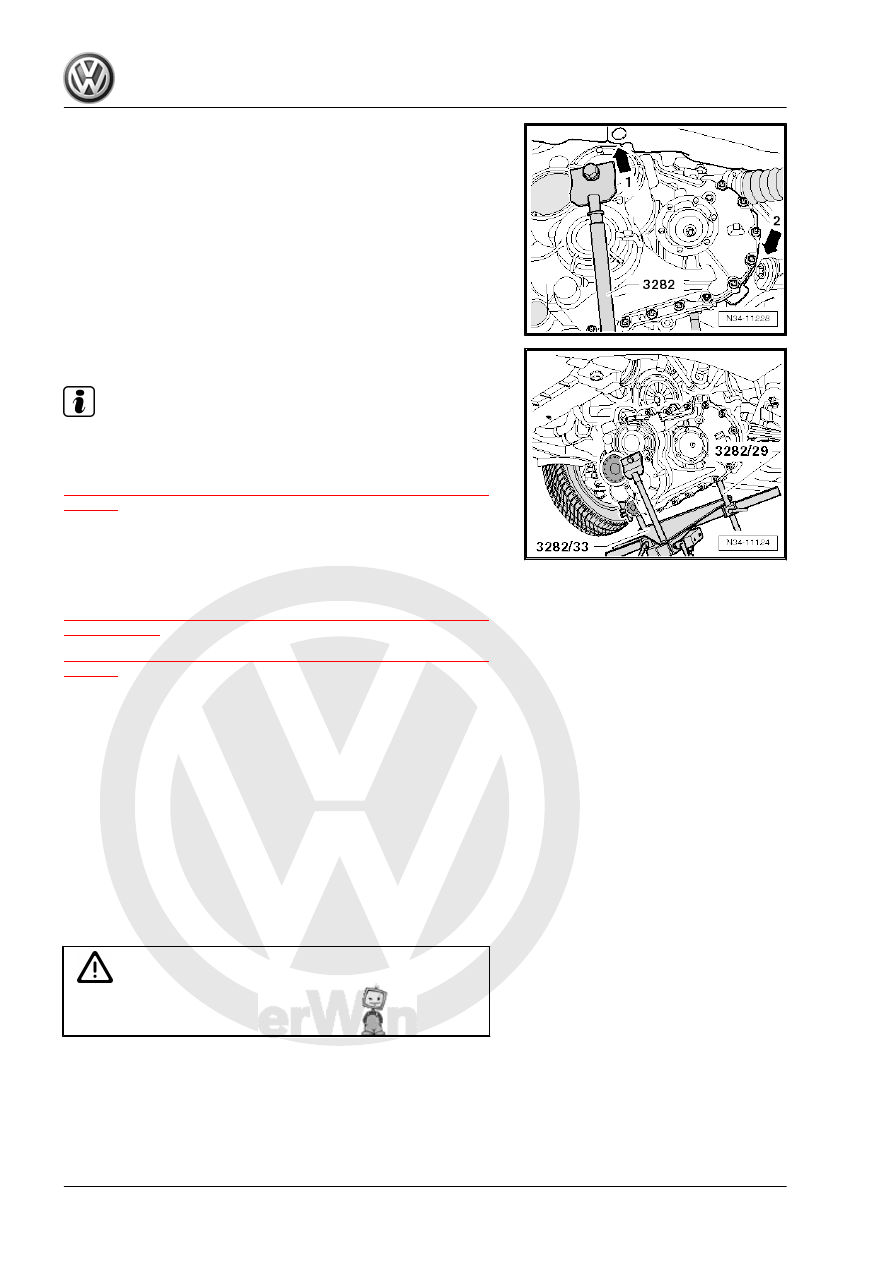

– Guide the transmission and the differential over the subframe

and swing them out.

– Be careful of the longitudinal member -arrow 1- and of the

subframe -arrow 2-.

– Move the transmission higher than the differential if necessa‐

ry.

– Carefully lower the transmission.

Note

Pay attention to the lines when lowering the transmission.

Install the transmission. Refer to

⇒ “2.2.2 Transmission, Installing, Vehicles with Gasoline Engine”,

2.2

Transmission, Installing

⇒ “2.2.1 Transmission, Installing, Vehicles with Turbo Diesel En‐

gine”, page 92

⇒ “2.2.2 Transmission, Installing, Vehicles with Gasoline Engine”,

2.2.1

Transmission, Installing, Vehicles with

Turbo Diesel Engine

Special tools and workshop equipment required

♦ Transmission Support - 3282-

♦ Transmission Support - Pins 29 - 3282/29-

♦ Transmission Support - Mounting Plate 33 - 3282/33-

♦ Engine and Gearbox Jack - VAS6931-

♦ Slide Hammer Set - Adapter 40 - VW771/40-

♦ Engine Support Bridge - 10-222A-

♦ Hose Clamp up to 25mm - 3094-

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Nut - Selector Lever to Shift Lever Shaft with Shift Lever Cover

♦ Lock Washer - Cable Retainer to Selector Lever

♦ Lock Washer - Cable Mounting Bracket to Cable Retainer