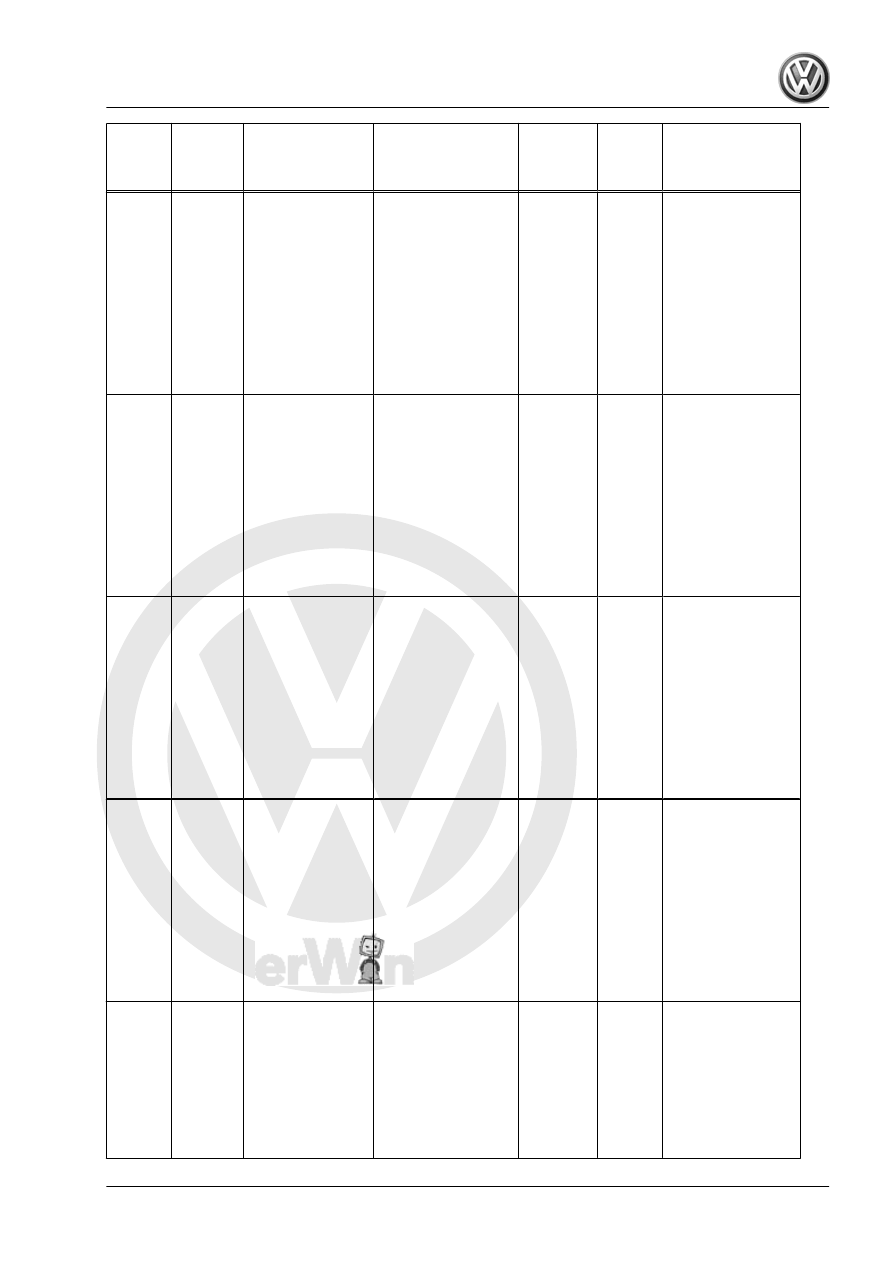

Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 131

DTC /

Descrip‐

tion

Monitor

Strategy

Descrip‐

tion

Malfunction Crite‐

ria and Threshold

Value

Secondary Parame‐

ters with Enable

Conditions

Monitoring

Time

Length

MIL Il‐

lum.

Component Diag‐

nostic Procedure

U0121

Lost

Commu‐

nication

With An‐

ti-Lock

Brake

System

(ABS)

Control

Module

CAN:

Brake

System

Control

Module

(BSCM)

CAN

Commu‐

nication

With

Brake

Unit

• Received CAN

message no

message

• Time after igni‐

tion on >= 0.5 s

• 0.5 s

• Contin‐

uous

• 2

DCY

– Check the CAN-

Bus circuits. If

there are any

other DTC’s

present check

them first.

– Refer to the

proper wiring

schematic for

terminal and

component lo‐

cation.

U0140

Lost

Commu‐

nication

With

Body

Control

Module

CAN:

Body

Control

Module

(BCM)

CAN

Commu‐

nication

With

Body

Control

Module

• Received CAN

message no

message

• Time after igni‐

tion on >= 0.5 s

• 0.5 s

• Contin‐

uous

• 2

DCY

– Check the CAN-

Bus circuits. If

there are any

other DTC’s

present check

them first.

– Refer to the

proper wiring

schematic for

terminal and

component lo‐

cation.

U0146

Lost

Commu‐

nication

With

Gate‐

way "A"

CAN:

Gateway

CAN

Commu‐

nication

With

Gateway

• Received CAN

message no

message

• Time after igni‐

tion on >= 0.5 s

• 0.5 s

• Contin‐

uous

• 2

DCY

– Check the CAN-

Bus circuits. If

there are any

other DTC’s

present check

them first.

– Refer to the

proper wiring

schematic for

terminal and

component lo‐

cation.

U0155

Lost

Commu‐

nication

With In‐

stru‐

ment

Panel

Cluster

(IPC)

Control

Module

CAN: In‐

strument

Cluster

CAN

Commu‐

nication

With In‐

strument

Cluster

Module

• Received CAN

message no

message

• Time after igni‐

tion on >= 0.5 s

• 0.5 s

• Contin‐

uous

• 2

DCY

– Check the CAN-

Bus circuits. If

there are any

other DTC’s

present check

them first.

– Refer to the

proper wiring

schematic for

terminal and

component lo‐

cation.

U0302

Soft‐

ware In‐

compati‐

bility

With

Trans‐

mission

Control

Module

ECM:

Coding

Code

Check Of

ECM

Concern‐

ing TCM

• Received AT

vehicle data

from TCM,

TCM signal

• 50.0 s

• Contin‐

uous

• 2

DCY

– Check for soft‐

ware updates

and TSB's. Re‐

program as nec‐

essary. If none

are found, refer

to appropriate

repair manual.

GTI 2014 ➤

Generic Scan Tool - Edition 04.2015

3. Diagnosis and Testing

197