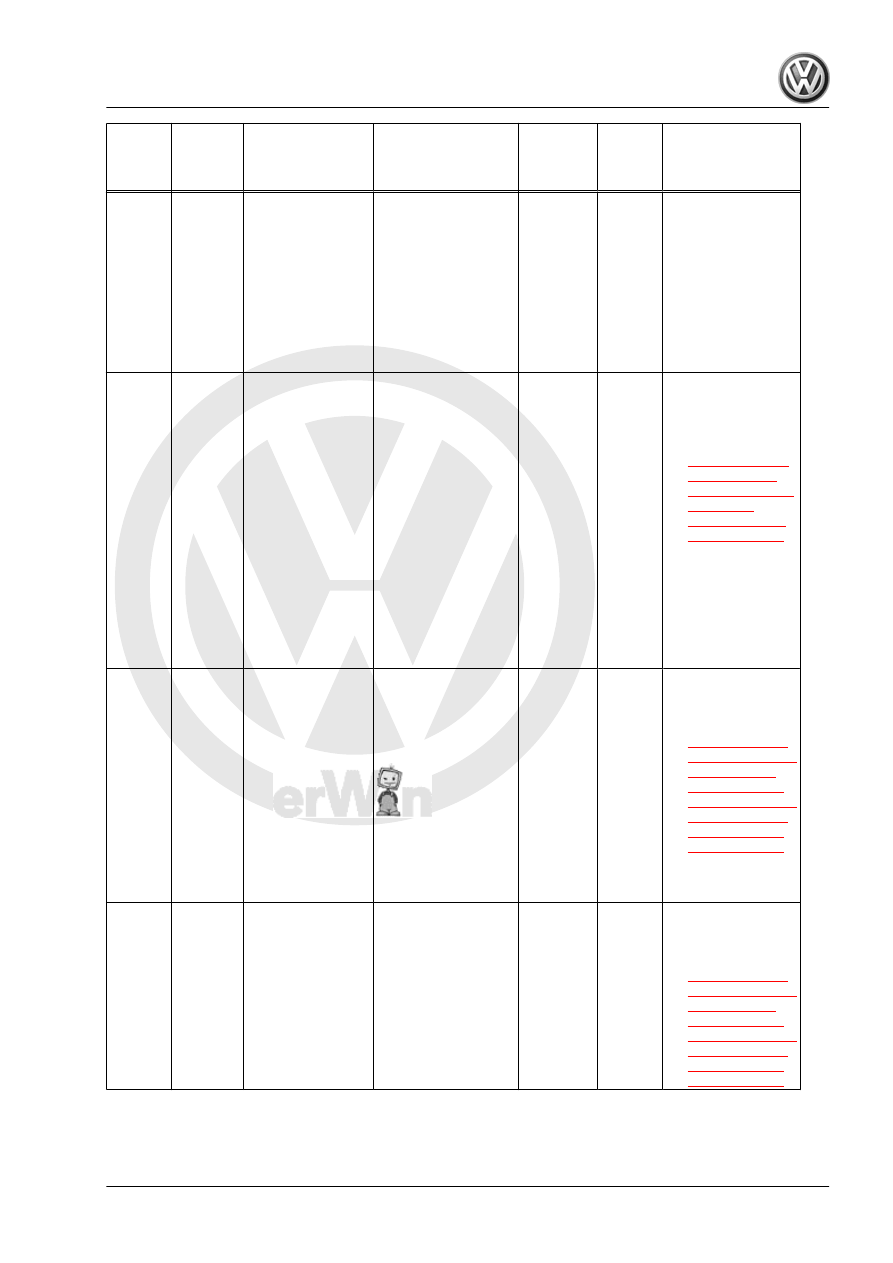

Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 129

DTC /

Descrip‐

tion

Monitor

Strategy

Descrip‐

tion

Malfunction Crite‐

ria and Threshold

Value

Secondary Parame‐

ters with Enable

Conditions

Monitoring

Time

Length

MIL Il‐

lum.

Component Diag‐

nostic Procedure

Fuel Con‐

trol Valve

Short To

Ground

Low Side

• Voltage low

side (hardware

values) < 1.92

– 2.10 V

• Ignition on

• Or

• Ignition off (dur‐

ing ECM keep

alive-time)

• And

• Actuator com‐

manded off

P2414

O2 Sen‐

sor Ex‐

haust

Sample

Error

Bank 1

Sensor

1

Oxygen

Sensors

Front Ra‐

tionality

Check

• Pump current

correction

(nernst-cell) >

0.00 A

• O2S front ready

• Fuel cut off not

active

• Cylinder shut off

not active

• Depending on

engine state:

• Engine part load

• Or

• Engine full load

• Or

• Engine idle for

time >= 5.0 s

• 10.0 s

• Contin‐

uous

• 2

DCY

– Check the Oxy‐

gen Sensor 1

Before Catalytic

Converter -

GX10- . Refer to

P2431

AIR Sys‐

tem Air

Flow/

Pres‐

sure

Sensor

Circuit

Range/

Per‐

for‐

mance

Bank 1

Secon‐

dary Air

System

Pressure

Sensor

Rationali‐

ty Check

• Difference be‐

tween AIR

pressure and

barometric

pressure > 6.0

kPa

• And

• Difference be‐

tween AIR

pressure and

intake manifold

pressure > 6.0

kPa

• Engine stop

• For time > 0.0 s

• 0.1 s

• Once /

DCY

• 2

DCY

– Check the Sec‐

ondary Air Sys‐

tem - GX24- .

Refer to

P2432

AIR Sys‐

tem Air

Flow/

Pres‐

sure

Sensor

Circuit

Low

Bank 1

Secon‐

dary Air

System

Pressure

Sensor

Out Of

Range

Low

• Sensor voltage

< 0.50 V

• 0.1 s

• Contin‐

uous

• 2

DCY

– Check the Sec‐

ondary Air Sys‐

tem - GX24- .

Refer to

GTI 2014 ➤

Generic Scan Tool - Edition 04.2015

3. Diagnosis and Testing

189