Toyota Corolla (2004+). Manual - part 86

05-698

DIAGNOSTICS

- WIRELESS DOOR LOCK CONTROL SYSTEM

13

CHECK DOOR CONTROL RECEIVER

(a) Reconnect the connector to the door control receiver, and

Door Control Receiver

check the voltage between the terminal and the body

ground, as shown in the illustration and table.

D3

B51174

Standard:

Symbols (Terminal No.)

Condition

Specified condition

No key in ignition key cylinder, all doors closed

RDA (D3-2) Body ground

1 V or less Approx. 6 - 7 V 1 V or less

and each transmitter switch OFF ON

NG Go to step 15

OK

14

CHECK WIRE HARNESS (DOOR CONTROL RECEIVER INSTRUMENT PANEL

J/B) (DOOR CONTROL RECEIVER OR INSTRUMENT PANEL J/B BODY

GROUND)

(a) Disconnect the door control receiver and instrument pan-

Door Control Receiver

(Wire Harness Side)

el J/B connectors.

D3

(b) Check the continuity between the terminals of the door

control receiver and instrument panel J/B connectors, as

shown in the illustration and table.

Standard:

Symbols (Terminal No.)

Specified condition

(Receiver - Instrument panel J/B)

RDA (D3-2) RDA (ID-8)

Continuity

RDA (D3-2) Body ground

Instrument Panel J/B

No continuity

RDA (ID-8) Body ground

(Wire Harness Side)

ID

NG REPAIR OR REPLACE HARNESS AND

CONNECTOR

B59377

OK

05-699

DIAGNOSTICS

-

WIRELESS DOOR LOCK CONTROL SYSTEM

15

REPLACE DOOR CONTROL RECEIVER WITH NORMAL ONE

NG Go to step 16

OK

REPLACE DOOR CONTROL RECEIVER

16

REPLACE INTEGRATION RELAY WITH NORMAL ONE

NG REPLACE INSTRUMENT PANEL JUNCTION

BLOCK ASSY

OK

REPLACE INTEGRATION RELAY

05-691

DIAGNOSTICS

- WIRELESS DOOR LOCK CONTROL SYSTEM

056BD-07

PROBLEM SYMPTOMS TABLE

Symptom

Suspected area

See page

1. Transmitter battery

2. Door control transmitter

Only wireless control function is inoperative

3. Door control receiver

05-692

(Prepare new or normal transmitter of the same type vehicle)

4. Unlock warning switch

5. Integration relay

6. Wire harness

05-688

DIAGNOSTICS

- WIRELESS DOOR LOCK CONTROL SYSTEM

056BC-02

TERMINALS OF ECU

1.

INSPECT INTEGRATION RELAY

Integration Relay Connector

(Wire Harness Side)

I11

B57790

(a) Disconnect the connector from the integration relay.

(b) Check the continuity between each terminal of the disconnected connector and the body ground, as

shown in the illustration and table.

Standard:

Symbols (Terminal No.)

Wiring color

Condition

Specified condition

LSWD (I11-19)

W Body ground

Driver’s door lock control knob LOCK UNLOCK

Body ground

LSWP (I11-18)

W-R Body ground

Front passenger’s door lock control knob LOCK UNLOCK

Body ground

No continuity Continuity

L1 (I11-9)

Door lock control switch (Manual operation)

L-W Body ground

Body ground

OFF LOCK

UL1 (I11-8)

Door lock control switch (Manual operation)

L Body ground

Body ground

OFF UNLOCK

L2 (I11-7)

Using key, front door lock cylinder

G Body ground

Continuity No continuity

Body ground

LOCK Other position

UL3 (I11-6)

Using key, driver’s door lock cylinder

L-Y Body ground

Body ground

UNLOCK Other position

Continuity No continuity

UL2 (I11-5)

Using key, front passenger’s door lock cylinder

L-B Body ground

Body ground

UNLOCK Other position

PCTY (I11-13)

R-W Body ground

Front passenger’s door fully closed Opened

No continuity Continuity

Body ground

If the result is not as specified, the vehicle’s side may malfunction.

(c)

Reconnect the connector and check the voltage between each terminal and the body ground, as

shown in the illustration and table.

Standard:

Symbols (Terminal No.)

Wiring color

Condition

Specified condition

ACTD (I11-1)

0 V 10 - 14 V

R Body ground

Driver’s door lock OFF ON

Body ground

1 V or less

HAZ (I11-25)

Transmitter LOCK or UNLOCK switch is pushed

0 V (Hazard not flashing)

Y-B Body ground

Body ground

Hazard warning switch ON

10 - 14 V (Hazard flashing)

If the result is not as specified, the integration relay may malfunction.

05-689

DIAGNOSTICS

- WIRELESS DOOR LOCK CONTROL SYSTEM

2.

INSPECT INSTRUMENTAL PANEL J/B (INTEGRATION RELAY)

Instrument Panel J/B (Integration Relay)

Instrument Panel J/B Side

IK

ID

Connector IA

IA

IG

IB

Instrument Panel J/B Side

Connector IB

IF

IH

IJ

+B

Instrument Panel J/B Side

Instrument Panel J/B Side

Instrument Panel J/B Side

Connector IK

Connector IF

Connector IJ

ACT+

ACT-

GND

KSW

Instrument Panel J/B Side

ACT+

Instrument Panel J/B Side

Connector ID

PRG

RDA

DCTY

Connector IH

B59376

B59378

ACT-

PRCTY

GND

B59532

05-690

DIAGNOSTICS

- WIRELESS DOOR LOCK CONTROL SYSTEM

(a) Disconnect the connectors IA, IB, ID, IF, IH and IJ of the instrument panel J/B.

(b) Check the continuity between each terminal of the disconnected connectors and the body ground, as

shown in the illustration and table.

Standard:

Symbols (Terminal No.)

Wiring color

Condition

Specified condition

DCTY (ID-1)

R-W Body ground

Driver’s door fully closed Opened

Body ground

PRCTY (ID-14)

R-B Body ground

Rear LH door fully closed Opened

No continuity Continuity

Body ground

PRCTY (ID-15)

R-Y Body ground

Rear RH door fully closed Opened

Body ground

KSW (IJ-8)

L-B Body ground

No key in ignition switch cylinder Key inserted

No continuity Continuity

Body ground

+B (IB-1)

W Body ground

Body ground

Constant

10

- 14 V

IG (IA-1)

W Body ground

Body ground

GND (IF-4)

W-B Body ground

Body ground

Constant

Continuity

GND (IH-10)

W-B Body ground

Body ground

If the result is not as specified, the vehicle’s side may malfunction.

(c)

Reconnect the connectors and check the voltage between each terminal and the body ground, as

shown in the illustration and table.

Standard:

Symbols (Terminal No.)

Wiring color

Condition

Specified condition

ACT+ (IK-2)

F Front door lock OFF ON

L Body ground

Body ground

F Rear RH door lock OFF ON

ACT- (IK-5)

F Front passenger’s door lock OFF ON

R Body ground

Body ground

F Rear RH door lock OFF ON

0 V 10 - 14 V

ACT+ (ID-9)

1 V or less

L Body ground

Body ground

Rear LH door lock OFF ON

ACT- (ID-20)

R Body ground

Body ground

1 V or less

RDA (ID-8)

No key in ignition key cylinder, all doors closed and

L-R Body ground

Approx. 6 - 7 V

Body ground

transmitter switch OFF ON

1 V or less

If the result is not as specified, the integration relay or instrument panel J/B assembly may malfunction.

05-685

DIAGNOSTICS

- WIRELESS DOOR LOCK CONTROL SYSTEM

WIRELESS DOOR LOCK CONTROL SYSTEM

05DUB-01

HOW TO PROCEED WITH TROUBLESHOOTING

HINT:

F

Troubleshooting of the wireless door lock control system is based on the premise that the power door

lock system is operating normally. Therefore, before troubleshooting the wireless door lock control sys-

tem, first make certain that the the power door lock system is operating normally.

F

Use this procedure to troubleshoot the wireless door lock control system.

1

VEHICLE BROUGHT TO WORKSHOP

2

CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

(See page 05-686)

3

PROBLEM SYMPTOMS TABLE (See page 05-691)

(a) If the fault is not listed on the problem symptoms table, proceed to A.

(b) If the fault is listed on the problem symptoms table, proceed to B.

B

Go to step 5

A

4

OVERALL ANALYSIS AND TROUBLESHOOTING

(a) Terminals of ECU (See page 05-688)

(b) On-vehicle inspection (See page 73-8)

5

ADJUST, REPAIR OR REPLACE

6

CONFIRMATION TEST

END

11-9

FUEL

- FUEL INJECTOR ASSY

FUEL INJECTOR ASSY

110FI-01

COMPONENTS

Clip

7.0 (71, 62 in.·lbf)

Cylinder Head Cover No. 2

EFI Fuel Pipe Clamp

19 (189, 14)

Fuel Tube Sub-assy

Fuel Delivery PIpe

Sub-assy

F O-ring

Fuel Injector Assy

9.0 (92, 80 in.·lbf)

F Insulator

No. 1 Spacer

Engine Wire

Ventilation Hose

N·m (kgf·cm, ft·lbf)

: Specified torque

F Non-reusable part

A65076

11-10

FUEL

- FUEL INJECTOR ASSY

110FJ-01

REPLACEMENT

1.

WORK FOR PREVENTING GASOLINE FROM SPILLING OUT (See page 11-1)

2.

REMOVE CYLINDER HEAD COVER NO.2

(a) Remove the 2 nuts, 2 clips and cylinder head cover.

A65077

3.

DISCONNECT VENTILATION HOSE

(a) Disconnect the ventilation hose from the cylinder head

cover.

A65078

4.

DISCONNECT ENGINE WIRE

(a) Disconnect the 4 fuel injector connectors.

(b) Remove the 3 wire harness clamps from the clamp brack-

ets.

A65079

5.

REMOVE EFI FUEL PIPE CLAMP

(a) Remove the EFI fuel pipe clamp.

A65080

11-11

FUEL

- FUEL INJECTOR ASSY

6.

DISCONNECT FUEL TUBE SUB-ASSY

(a) Using a SST, disconnect the fuel tube.

Retainer

SST

09268-21010

(at 4 places)

(1)

Assemble the SST to the connection as shown.

(2)

Turn the SST, align the retainers inside the connec-

tor with the SST chamfered parts and insert the SST

into the connector.

(3)

Slide the SST and the connector together towards

Turn

the fuel tube assembly.

NOTICE:

SST

F

Check if there is dirt mud on the pipe and around the

connector before disconnecting them and clean the

dirt away.

Insert

F

Do not bent, fold and rotate the nylon tube.

F

When the connector and the pipe are stuck, push and

pull the connector to free to disconnect and

pull it out.

F

Prevent the disconnected pipe and connector from

damaging and mixing foreign objects by covering

A65081

them with a vinyl bag.

Retainer

O-ring

Pipe

Nylon Tube

Housing

A65082

7.

REMOVE FUEL DELIVERY PIPE SUB-ASSY

(a) Remove the 3 bolts and fuel delivery pipe together with

the 4 fuel injectors.

NOTICE:

Be careful not to drop the fuel injectors when removing the

fuel delivery pipe.

A65083

(b) Remove the 2 spacers from the cylinder head.

A65084

11-12

FUEL

- FUEL INJECTOR ASSY

8.

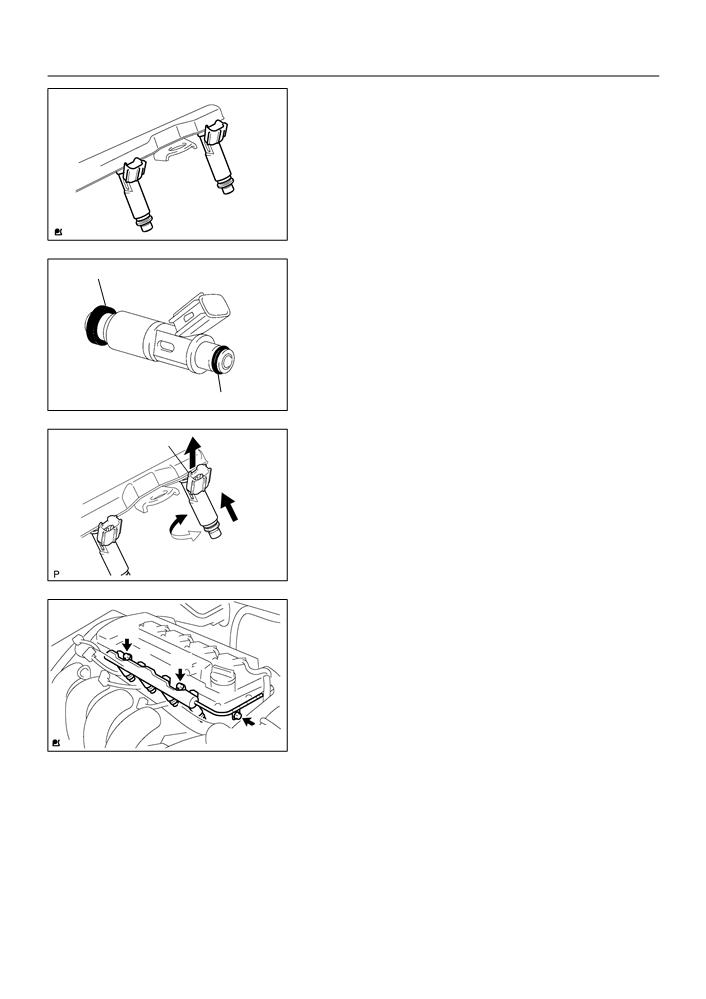

REMOVE FUEL INJECTOR ASSY

(a) Pull out the 4 fuel injectors from the fuel delivery pipe.

A65085

9.

INSTALL FUEL INJECTOR ASSY

New Insulator

(a) Install a new insulator to the each fuel injector.

(b) Apply a light coat of spindle oil or gasoline to a new O-

ring, and install it to the each fuel injector.

NOTICE:

Never use engine, gear or brake oil.

Apply a light coat of gasoline

A60598

(c)

Apply a light coat of spindle oil or gasoline on the place

Connector

Upward

where the fuel delivery pipe touches on the O-ring.

(d) While turning the fuel injector clockwise and counter-

clockwise, and push it to the fuel delivery pipe.

NOTICE:

F

Be careful not twist the O-ring.

Push

F

After installing the fuel injectors, Check that they

Turn

turns smoothly. If the fuel injector does not, reinstall

A60600

it with a new O-ring.

10. INSTALL FUEL DELIVERY PIPE SUB-ASSY

(a) Install the 2 spacers to the cylinder head.

A

(b) Install the fuel delivery pipe together with the 4 fuel injec-

tors with the 3 bolts.

A

Torque:

Bolt A 19 N m (194 kgf cm, 14 ft lbf)

Bolt B 9.0 N m (92 kgf cm, 80 in. lbf)

NOTICE:

B

A65083

F

Be careful not drop the fuel injectors when installing

the fuel delivery pipe.

F

Check that the fuel injectors rotate smoothly after

installing the fuel delivery pipe.

11.

CONNECT FUEL TUBE SUB-ASSY

(a)

Connect the fuel tube to the fuel delivery pipe.

NOTICE:

F

Check if there is any damage or foreign objects on the connected part of the fuel tube.

F

After connecting, check if the fuel tube and the connector are securely connected by pulling

them.

11-13

FUEL

-

FUEL INJECTOR ASSY

12. INSTALL CYLINDER HEAD COVER NO.2

(a) Install the cylinder head cover with the 2 nuts and 2 clips.

Torque: 7.0 N m (71 kgf cm, 62 in. lbf)

13. CHECK FUEL LEAK (See page 11-1)

11-14

FUEL

- FUEL PUMP ASSY

FUEL PUMP ASSY

110FK-01

COMPONENTS

Rear Seat Cushion Assy

Rear Floor Service Hole Cover

Fuel Tank Main Tube Sub-assy

6.0 (61, 53 in. lbf)

Fuel Evaporation Tube Sub-assy No 2

X8

Fuel Tank Vent Tube Set Plate

Tube Joint Clip

Fuel Pump Assembly

F Gasket

N·m (kgf·cm, ft·lbf)

: Specified torque

F Non-reusable part

A65087

11-15

FUEL

- FUEL PUMP ASSY

Vapor Pressure Sensor Assy

Tube Joint Clip

Fuel Pump Harness

Fuel Suction Plate Sub-assy

Fuel Filter

Fuel Sender Gauge Assy

Fuel Pump Assy

F O-ring

Fuel Pressure Regulator Assy

Fuel Pump Filter

F Clip

Fuel Pump Cushion Rubber

Fuel Suction Support No. 2

F Non-reusable part

A65021

11-16

FUEL

- FUEL PUMP ASSY

110FL-01

Removal & Installation and Disassembly & Reassembly

1.

REMOVE BENCH TYPE REAR SEAT CUSHION ASSY (See page 72-6, 72-8)

2.

REMOVE REAR FLOOR SERVICE HOLE COVER

(a) Remove the rear service hole cover.

Butyl Tape

A65023

(b) Disconnect the fuel pump and vapor pressure sensor

connector.

A65088

3.

WORK FOR PREVENTING GASOLINE FROM SPILLING OUT

(a) Start the engine.

(b) After the engine has stopped on the its own, turn the ignition switch to lock.

4.

DISCONNECT FUEL TANK MAIN TUBE SUB-ASSY

(a) Remove the tube joint clip, and pull out the fuel tank main

tube.

NOTICE:

F

Check if there is any dirt like mud around the fuel tube

joint before this work and clean dirt away.

F

Be careful of dirt like mud because the fuel tube joint

has an O-ring to seal the fuel tube joint and fuel suc-

A65024

tion plate.

F

Do not use any tool in this work.

F

Do not bend or twist the nylon tube by force.

Fuel Tube Joint

Nylon Tube

F

After disconnecting, cover the fuel t ube joint with a vi-

nyl bag.

F

When the fuel tube joint and fuel suction plate are

stuck, pinch the fuel tank main tube between fingers,

O-ring

Tube Joint Clip

and turn it carefully to free and then disconnect the

fuel tank main tube.

Fuel Suction Plate

A60575