Toyota Corolla (2004+). Manual - part 49

05-642

DIAGNOSTICS

- COMBINATION METER

I30037

05-643

DIAGNOSTICS

- COMBINATION METER

18

28

2

BEAM-

13

17

DOOR

20

14

I/F I/F

6

TURN L

24

TURN R

8

I/F

25

30

I/F

5

9

I/F

4

26

CPU

I/F

19

LCD

OUTSIDE TEMP

D-BELT

1

LCD

I/F

ODO/TRIP

7

SPEED

22

FUEL WRN

TACHO

11

I/F

FUEL

12

I/F

TEMP

16

I/F

BUZZER

10

CHG

31

32

CHK E/G

33

O/D OFF

3

36

BRAKE

35

WASHER LEVEL (Canada)

34

37

ABS

OIL P

21

39

AIR BAG

CRUISE

23

I32739

05-644

DIAGNOSTICS

- COMBINATION METER

Terminal No.

Wire harness side

1

Ground (Signal Ground)

C9

2

Ground (Power Ground)

3

ECM

4

GAUGE Fuse

5

DOME Fuse

6

Front Passenger Seat Belt Warning Indicator

7

Fuel sender gauge

8

ECM

9

Skid Control ECU (w/ ABS), Vehicle Speed Control Sensor (w/o ABS)

10

Cruise Control ECU, ECM

11

Buckle Switch RH

12

Buckle Switch LH

13

Ground

14

HEAD RH UPR Fuse

15

-

16

Unlock Warning Switch

17

Driver Side Courtesy Switch

18

Tail Relay (USA), Combination Switch (Canada)

19

ECM

20

Except Driver Side Courtesy Switch

21

Engine Oil Pressure Switch

22

Fuel sender gauge

23

Cruise Control ECU

24

Turn Signal Flasher

25

Turn Signal Flasher

26

Ambient Temperature Sensor

28

Rheostat

30

Ambient Temperature Sensor

31

Alternator

32

GAUGE Fuse

33

ECM

34

Washer Level Sensor (Canada)

35

Brake Fluid Level Warning Switch

36

Skid Control ECU with Actuator (w/ ABS), Ground (w/o ABS)

37

Skid Control ECU with Actuator (w/ ABS), Ground (w/o ABS)

38

-

39

Airbag Sensor Assembly

40

-

05-666

DIAGNOSTICS

- COMBINATION METER

057T5-02

MALFUNCTION IN CLOCK

WIRING DIAGRAM

Clock

TAIL Relay (USA)

3

G

Combination SW (Canada)

RH J/B

11

18

2

3A

3A

W-B

W-B

10

5

4

3A

3A

GR

1

GR

Instrument Panel J/B

8

CIG

6

IF

IF

I10 Ignition SW

AM1

1

12

1

3

IB

IF

W

W

L-R

AM1

ACC

Center J/B

7

4

20

16

IC

IL

4C

4C

L-W

L-W

L-W

Engine Room J/B, R/B

A

J7

DOME

J/C

2

1

1

1

ALT

1

FL MAIN

2

1

1C

1A

B

Battery

IG

I32382

INSPECTION PROCEDURE

1

INSPECT FUSE

(a) Check the continuity in CIG fuse.

(b) Check the continuity in DOME fuse.

NG REPLACE FUSE

OK

05-667

DIAGNOSTICS

- COMBINATION METER

2

INSPECT HARNESS OR CONNECTOR

(a) Check voltage.

(1)

Remove the clock assy with connector still con-

nected.

(2)

Measure voltage between terminal 1 (+B) of clock

assy connector and body ground.

Standard voltage: 10 - 14 V

(3)

Turn the ignition switch to ACC.

+B E ILL ACC

(4)

Measure voltage between terminal 4 (ACC) of clock

I32727

assy connector and body ground.

Standard voltage: 10 - 14 V

(b) Check continuity.

(1)

Check continuity Between terminal 2 (E) of clock

assy connector and body ground.

OK: Continuity exists

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

REPLACE CLOCK ASSY

05-655

DIAGNOSTICS

- COMBINATION METER

057KJ-02

MALFUNCTION IN FUEL RECEIVER GAUGE

WIRING DIAGRAM

F10

Combination Meter

Fuel Pump

Fuel Sender

22

13

BR

BR

ID2

C9

FUEL

2

3

EARTH

7

5

Y

Y

C9

FUEL

ID2

I32726

INSPECTION PROCEDERE

1

INSPECT FUEL SENDER GAGE ASSY

(a) Disconnect the connector fuel sender gauge.

(b) Check the float position between E and F and measure

the resistance between terminals 2 and 3 of the connec-

tor. Check that the resistance value changes continuous-

ly.

3

2

1

Standard:

Float level

Float position mm (in.)

Resistance (W)

F

64.5

(2.53)

3 (0.12)

15.0

1

e-3-1-B

E51362

1/2

11.6

(0.45)

3 (0.12)

54.7

3

E

52.7

(2.07)

3 (0.12)

107.0

1

F

12mm

1/2

(0 in.)

NG REPLACE FUEL SENDER GAGE ASSY

E

I32082

OK

05-656

DIAGNOSTICS

- COMBINATION METER

2

CHECK HARNESS AND CONNECTOR(BETWEEN FUEL SENDER GAGE AND

COMBINATION METER ASSY)

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK AND REPLACE COMBINATION METER ASSY

05-650

DIAGNOSTICS

- COMBINATION METER

057KG-04

MALFUNCTION IN SPEEDOMETER

WIRING DIAGRAM

Vehicle Speed Sensor

Combination Meter

3

4

9

(*1)

(*1)

SP1

V1

II2

C9

SP IN

W-G

W-G

W-G

Skid Control ECU

with Actuator

17

14

(*2)

(*2)

SP1

S1

IA6

W-G

W-G

*1: w/o ABS

*2: w/ ABS

I32764

INSPECTION PROCEDURE

1

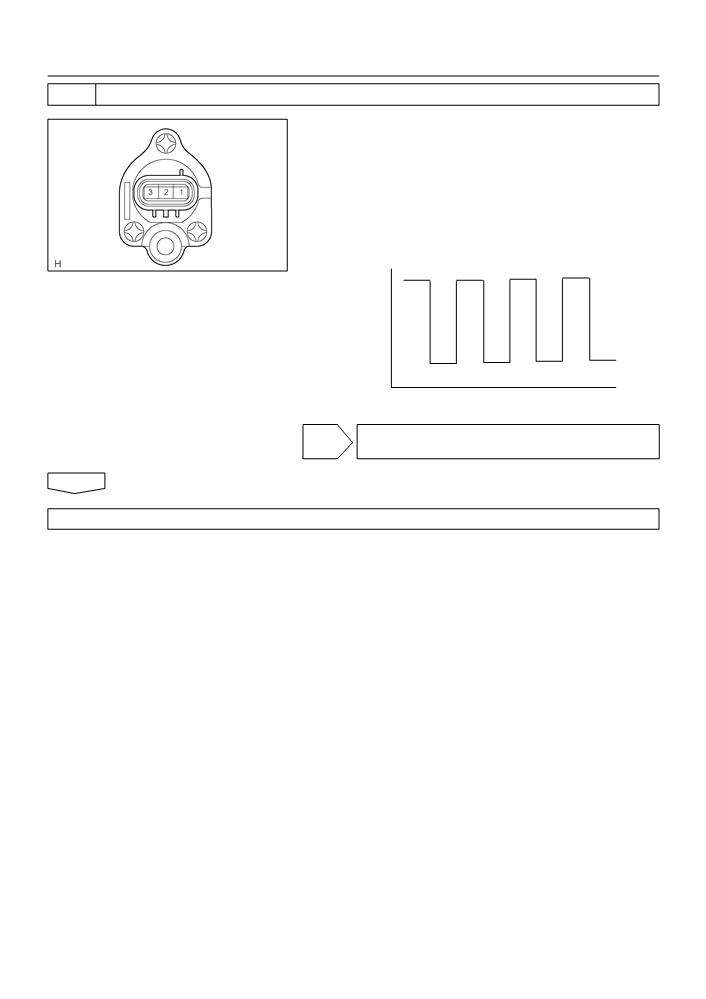

CHECK COMBINATION METER ASSY

(a) Remove the combination meter assy with connector still

connected.

(b) Check voltage.

(1)

Jack up either of the front wheels.

(2)

Shift the shift lever to neutral.

(3)

Turn the ignition switch to ON.

(4)

Measure the voltage between terminals C9-9 of

SP IN

combination meter assy and body ground when

I30040

front wheel is turning slowly.

Standard voltage:

Voltage is generated intermittently.

10 - 14V

0

Turn the wheel

05-651

DIAGNOSTICS

-

COMBINATION METER

Result:

A

B

C

OK

NG (w/ ABS)

NG (w/o ABS)

B

Go to step 2

C Go to step 3

A

CHECK AND REPLACE COMBINATION METER ASSY

2

CHECK OBD II SCAN TOOL OR HAND-HELD TESTER

(a) Check output value of skid control ECU.

(1)

Connect the hand-held tester to DLC3.

(2)

Turn the ignition switch to ON and push the hand-held tester main switch ON.

(3)

Select the DATA LIST mode on the hand-held tester.

(4)

Check that there is no difference between the speed value output from the speed sensor dis-

played by the hand-held tester and the speed value displayed by the speedometer when driving

the vehicle.

OK: There is almost no difference from the displayed speed value.

NG GO TO BRAKE SYSTEM

OK

REPAIR OR REPLACE HARNESS OR CONNECTOR

05-652

DIAGNOSTICS

- COMBINATION METER

3

INSPECT SPEEDOMETER SENSOR

(a) Check voltage.

(1)

Shift the shift lever to neutral.

(2)

Jack up either of the front wheel.

(3)

Turn the ignition switch to ON.

(4)

Measure voltage between terminals 3 and 2 of

speed sensor when the front wheel is turning slowly.

Standard voltage:

Voltage is generated intermittently.

I31248

10 - 14V

0

Turn the wheel

NG CHECK AND REPLACE SPEEDOMETER

SENSOR

OK

REPAIR OR REPLACE HARNESS OR CONNECTOR

05-653

DIAGNOSTICS

- COMBINATION METER

057KH-02

MALFUNCTION IN TACHOMETER

WIRING DIAGRAM

ECM

Combination Meter

5

19

TACH

E6

C9

TACHO

B

I32725

INSPECTION PROCEDURE

1

READ VALUE OF HAND-HELD TESTER

(a) Check output value of ECM.

(1)

Connect the hand-held tester to DLC3.

(2)

Turn the ignition switch to ON and push the hand-held tester main switch ON.

(3)

Select the DATA LIST mode on the hand-held tester.

Mesurement Item / Range

Item

Condition

Specified Condition

(Display)

Engine Speed /

ENGINE SPD

With Engine Idling

650 - 750rpm

Min.: 0 rpm, Max.: 16,383rpm

NG GO TO ENGINE CONTROL SYSTEM

OK

05-654

DIAGNOSTICS

- COMBINATION METER

2

INSPECT COMBINATION METER ASSY

(REFERENCE) INSPECTION USING OSCILLOSCOPE

(a) Check the input signal waveform.

(1)

Remove the combination meter assy with connec-

tors still connected.

(2)

Connect the oscilloscope to the terminals C9-19 of

combination meter assy and body ground.

(3)

Start engine.

TACHO

(4)

Check the signal waveform.

I30040

Item

Contents

Tool setting

10 V/ DIV, 20 ms/ DV

Vehicle condition

Engine idle speed

E50835

OK CHECK AND REPLACE COMBINATION METER

ASSY

NG

3

CHECK HARNESS AND CONNECTOR(BETWEEN ECM AND COMBINATION

METER ASSY)

(a) Remove the combination meter.

(b) Check the continuity between terminals 5 (TACH) of ECM and C9-19 of combination meter connector.

Standard: There is continuity.

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK AND REPLACE ECM

05-657

DIAGNOSTICS

- COMBINATION METER

057KI-02

MALFUNCTION IN WATER TEMPERATURE RECEIVER GAUGE

WIRING DIAGRAM

ECM

Combination Meter

14

8

THWO

E5

C9

TEMP

Y-R

I32725

INSPECTION PROCEDURE

1

READ VALUE OF HAND-HELD TESTER

(a) Check output value of ECM.

(1)

Connect the hand-held tester to DLC3.

(2)

Turn the ignition switch to ON and push the hand-held tester main switch ON.

(3)

Select the DATA LIST mode on the hand-held tester.

Mesurement Item /Range

Item

Condition

Specified Condition

(Display)

Coolant Temperature /

COOLANT TEMP

After Warming Up

80 - 95FC (176 - 203FF)

Min.: -40FC, Max.: 140FC

NG GO TO ENGINE CONTROL SYSTEM

OK

05-658

DIAGNOSTICS

- COMBINATION METER

2

INSPECT COMBINATION METER ASSY

(REFERENCE) INSPECTION USING OSCILLOSCOPE

(a) Check the input signal waveform.

(1)

Remove the combination meter with connectors still

connected.

(2)

Connect the oscilloscope to the terminals C9-8 of

combination meter assy and body ground.

(3)

Start engine.

TEMP

(4)

Check the signal waveform.

I32114

Item

Contents

Tool setting

5 V/ DIV, 100 ms/ DV

Vehicle condition

Ignition switch ON

I32122

OK CHECK AND REPLACE COMBINATION METER

ASSY

NG

3

CHECK HARNESS AND CONNECTOR(BETWEEN ECM AND COMBINATION

METER ASSY)

(a) Remove the combination meter.

(b) Check the continuity between terminals 14 (THWO) of ECM and C9-8 of combination meter connector.

Standard: There is continuity.

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK AND REPLACE ECM

05-661

DIAGNOSTICS

- COMBINATION METER

057T4-02

SEAT BELT WARNING LAMP FOR DRIVER’S SEAT DOES NOT

OPERATE

WIRING DIAGRAM

B6

Buckle SW LH

Airbag Sensor Assy

Seat Position Sensor

Combination Meter

11

2

LBE+

A12

LBE+

G

1

12

3

3

4

L

IG1

C9

D-BELT SW

LSP+

A12

LSP+

G-Y

G-Y

G-W

4

1

LSP-

A12

5

LSP-

LBE-

R-B

W-B

J7

RH J/B

J/C

11

15

2

A

3A

3A

IG1

W-B

W-B

IG

I32384

INSPECTION PROCEDURE

1

CHECK COMBINATION METER ASSY

(a) Ground terminal C9-12 on the combination meter side.

(b) Check that the warning lightlights up.

OK: Warning light lights up.

D BELT SW

NG CHECK AND REPLACE COMBINATION METER

I30040

ASSY

OK