Toyota Corolla (2004+). Manual - part 48

DIAGNOSTICS

-

ELECTRONIC CONTROLLED AUTOMATIC

05-379

TRANSAXLE [ECT] (April, 2003)

05DU3-01

DTC

P0705

TRANSMISSION RANGE SENSOR CIRCUIT

MALFUNCTION (PRNDL INPUT)

DTC

P0850

PARK/NEUTRAL SWITCH INPUT CIRCUIT

CIRCUIT DESCRIPTION

The park/neutral position switch detects the shift lever position and sends signals to the ECM.

DTC No.

DTC Detecting Condition

Trouble Area

2 or more switches are ON simultaneously for P, R, N, 2 and L

P0705

positions (2-trip detection logic)

Park/neutral position switch remains ON (P, N position) during

F Open or short in park/neutral position switch circuit

driving under conditions (a) and (b) for 30 sec. (2-trip detection

F Park/neutral position switch

P0850

logic)

F ECM

(a) Vehicle speed: 70 km/h (44 mph) or more

(b) Engine speed: 1,500 - 2,500 rpm

MONITOR DESCRIPTION

The park/neutral position switch detects the gearshift position and sends a signal to the ECM.

For security, the park/neutral position switch detects the gearshift position so that engine can be started only

when the vehicle is in P or N shift position.

When the park/neutral position switch sends more than one signal at a time from switch positions P, R, N,

2, or L the ECM interprets this as a fault in the switch. The ECM will turn on the MIL.

MONITOR STRATEGY

P0705

Shift lever position select switch/Verify switch

Related DTCs

P0705

input

Required sensors/Components

Park/neutral position switch

Frequency of operation

Continuous

Duration

0.5 sec.

MIL operation

2 driving cycles

Sequence of operation

None

P0850

Related DTCs

P0850

Park/neutral position switch/Verify switch cycling

Required sensors/Components

Park/neutral position switch

Frequency of operation

Continuous

Duration

30 sec.

MIL operation

2 driving cycles

Sequence of operation

None

05-380

DIAGNOSTICS

- ELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (April, 2003)

TYPICAL ENABLING CONDITION

P0705

Specification

Item

Minimum

Maximum

The monitor will run whenever the follow-

See page 05-369

ing DTCs are not present.

The typical enabling condition is not avail-

-

able.

P0805

Specification

Item

Minimum

Maximum

The monitor will run whenever the follow-

See page 05-369

ing DTCs are not present.

Vehicle speed

70 km/h (43 mph) or more

-

Engine speed

1,500 rpm or more

2,700 rpm or less

Intake air amount per revolution

0.43 g/rev. or more

-

TYPICAL MALFUNCTION THRESHOLDS

P0705

Detection criteria

Threshold

Number of the following signal input at the same time.

2 or more

Park/neutral position switch

ON

L shift position switch

ON

2 shift position switch

ON

R shift position switch

ON

P0850

Detection criteria

Threshold

PNP signal

ON

COMPONENT OPERATING RANGE

Parameter

Standard value

Park/neutral position switch

The park/neutral position switch sends only one signal to the ECM.

DIAGNOSTICS

- ELECTRONIC CONTROLLED AUTOMATIC

05-381

TRANSAXLE [ECT] (April, 2003)

WIRING DIAGRAM

J/C

ECM

A

G

R

To

J2

J2

ST Relay

B

G

G

9

A2

B

J2

J2

E4

STA

Park/Neutral Position SW

A

E

8

R

R

J2

J3

E4

NSW

6

9

2

8

LG-B

LG-B

II1

E5

L

LL

8

5

9

LG

LG

II1

E5

2

2L 4

3

RB

13

R-B

R-B

II2

RL 2

To

11

1

Combination Mater

RH J/B

E5

R

5

14

20

22

R-W

R-W

R-W

R-W

II2

3B

3B

B

B

12

R J4 J/C

R

B-Y

II2

R-B

R-B

4

2

Instrument Panel J/B

ST2

IG1

I10

9

10

Ignition SW

IK

IK

AM2

AM1

2

GAUGE

R-W

5

1

IG

Engine Room J/B and R/B

B-Y

IG1 Relay

1

ALT

1

1

W W

W

1A

1D

IA

1

2

W

5

3

2

4

B

MAIN

IF

IF

B-R

1

2

1

12

AM1

1

1

2

1

IF

IB

W

1C

2

IA4

6

AM2

3

W-B

IM

IM

FL MAIN

B

A

B-R

J6

J/C

W

W-B

Battery

IE

G27785

05-382

DIAGNOSTICS

- ELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (April, 2003)

INSPECTION PROCEDURE

1

INSPECT PARK/NEUTRAL POSITION SWITCH ASSY

(a) Disconnect the park/neutral position switch connector.

Switch Side:

(Connector Front View):

(b) Measure resistance according to the value(s) in the table

below when the shift lever is moved to each position.

Standard:

Shift Position

Tester Connection

Specified Condition

P

Below 1 W

1 - 3 and 6 - 9

Except P

10 kW or higher

R

Below 1 W

A2

G27076

2- 3

Except R

10 kW or higher

N

Below 1 W

3 - 5 and 6 - 9

Except N

10 kW or higher

D

Below 1 W

3 - 7

Except D

10 kW or higher

2

Below 1 W

3 - 4

Except 2

10 kW or higher

L

Below 1 W

3- 8

Except L

10 kW or higher

NG REPLACE PARK/NEUTRAL POSITION SWITCH

ASSY (See page 40-3)

OK

DIAGNOSTICS

- ELECTRONIC CONTROLLED AUTOMATIC

05-383

TRANSAXLE [ECT] (April, 2003)

2

CHECK HARNESS AND CONNECTOR(PARK/NEUTRAL POSITION SWITCH -

ECM)

(a) Connect the the park/neutral position switch connector.

(b) Turn the ignition switch to the ON position, and measure

E3

E4

E5

E6

the voltage according to the value(s) in the table below

when the shift lever is moved to each position.

ECM:

NSW(+)

L(+)

R(+)

2(+)

C96070

Standard:

Shift Position

Tester Connection

Specified condition

P and N

Below 1 V

E4

- 8

(NSW) - Body ground

Except P and N

10 to 14 V

R

10 to 14 V*

E5 - 11 (R) - Body ground

Except R

Below 1 V

2

10 to 14 V

E5 - 9 (2) - Body ground

Except 2

Below 1 V

L

10 to 14 V

E5

- 8

(L) - Body ground

Except L

Below 1 V

HINT:

*: The voltage will drop slightly due to lighting up of the back up

light.

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR (See page 01-30)

OK

REPLACE ECM (See page 10-11)

05-346

DIAGNOSTICS

- ELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (April, 2003)

0527H-17

HOW TO PROCEED WITH TROUBLESHOOTING

The hand-held tester can be used at step 3, 4, 6, 9.

1

Vehicle Brought to Workshop

2

Customer Problem Analysis (See page

05-349)

3

Connect the OBD II scan tool or hand-held tester to DLC3

4

Check and Clear DTC and Freeze Frame Data (See page

05-353)

5

Visual Inspection

6

Setting the Check Mode Diagnosis (See page

05-354)

7

Problem Symptom Confirmation (See page

05-356)

Symptom does not occur: Go to step 8

Symptom occur: Go to step 9

8

Symptom Simulation (See page

01-20)

9

DTC Check (See page 05-353)

DTC is not output: Go to step 10

DTC is output: Go to step 18

DIAGNOSTICS

-

ELECTRONIC CONTROLLED AUTOMATIC

05-347

TRANSAXLE [ECT] (April, 2003)

10

Basic Inspection (See page

40-2, 40-6 and 40-44)

NG Go to step 20

OK

11

Mechanical System Test (See page

05-358)

NG Go to step 17

OK

12

Hydraulic Test (See page

05-360)

NG Go to step 17

OK

13

Manual Shifting Test (See page

05-361)

NG Go to step 15

OK

14

Problem Symptoms Table Chapter 1 (See page

05-374)

NG Go to step 19

OK

15

Problem Symptoms Table Chapter 2 (See page

05-374)

NG Go to step 17

OK

16

Problem Symptoms Table Chapter 3 (See page

05-374)

NG

17

Part Inspection

Go to step 20

18

DTC Chart (See page 05-372)

05-348

DIAGNOSTICS

- ELECTRONIC CONTROLLED AUTOMATIC

TRANSAXLE [ECT] (April, 2003)

19

Circuit Inspection

20

Identification of Problem

21

Repair

22

Confirmation Test

End

05-668

DIAGNOSTICS

- COMBINATION METER

057KO-04

THE AMBIENT TEMPERATURE DOES NOT DISPLAY

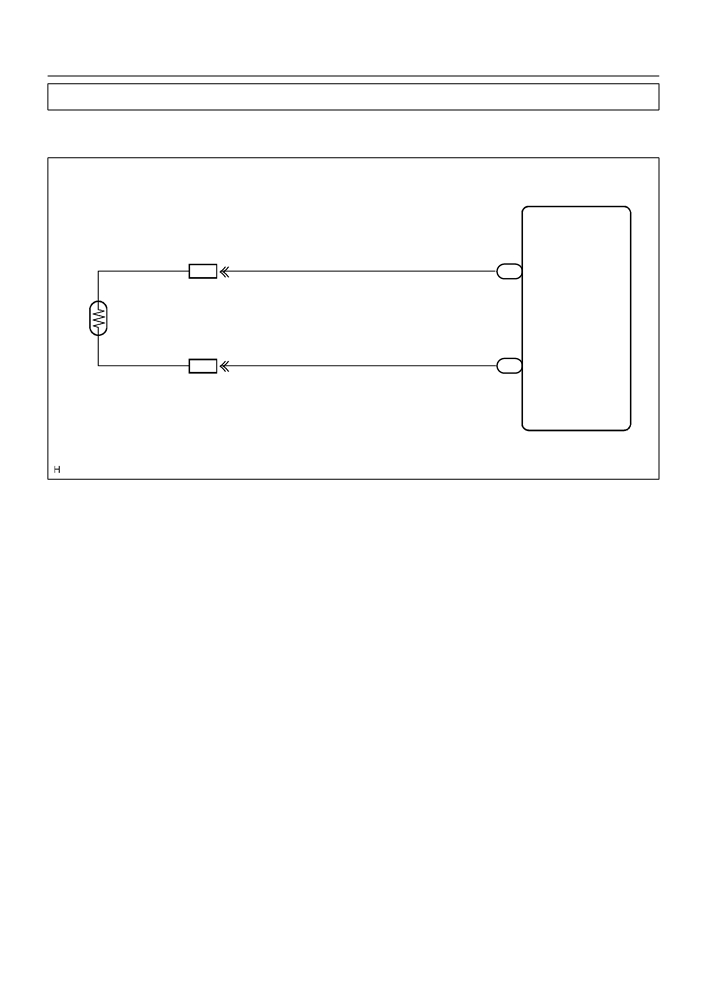

WIRING DIAGRAM

Combination Meter

3

26

IA6

C9

OUT SIDE TEMP+

B

B

1

A7

Ambient

Temperature

2

Sensor

10

30

IA6

C9

OUT SIDE TEMP-

B-L

B-L

I37764

05-669

DIAGNOSTICS

- COMBINATION METER

INSPECTION PROCEDURE

1

INSPECT OUTER AMBIENT TEMPERATURE SENSOR

(a) Remove cooler (ambient temp. sensor) thermistor.

(b) Measure resistance between terminals 1 and 2 of cooler

(ambient temp. sensor) thermistor connector at each tem-

perature.

Resistance:

1

2

at 0 FC (0 FF) : 9.097 - 9.701 k W

at 25 FC (77 FF) : 2.725 - 2.865 k W

HINT:

I30487

As the temperature increases, the resistance decreases.

Resistance:

Resistance (kW)

Temperature (FC)

I30156

NG REPLACE OUTER AMBIENT TEMPERATURE

SENSOR

OK

2

CHECK HARNESS AND CONNECTOR

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK AND REPLACE COMBINATION METER ASSY

05-639

DIAGNOSTICS

- COMBINATION METER

057KB-02

CUSTOMER PROBLEM ANALYSIS CHECK

COMBINATION METER Check Sheet

Inspector’s name:

Registration No.

Customer’s Name

Registration Year

Frame No.

Date of Vehicle

Km

Odometer Reading

Brought in

Mile

Date Problem First Occurred

How Often Problem Occurs

Continuous

Intermittent (

Times a day)

Weather

Fine

Cloudy

Snowy

Other

Temperature

Approx.

Malfunction in speedometer

Malfunction in tachometer

Malfunction in fuel receiver gauge

Malfunction in water temperature receiver

gauge

Key unlock warning buzzer does not sound

Light auto-turn off warning buzzer does not sound

Malfunction in driver’s seat belt warning buzzer

All buzzers do not sound

I30045

05-648

DIAGNOSTICS

- COMBINATION METER

057T2-02

ENTIRE COMBINATION METER DOES NOT OPERATE

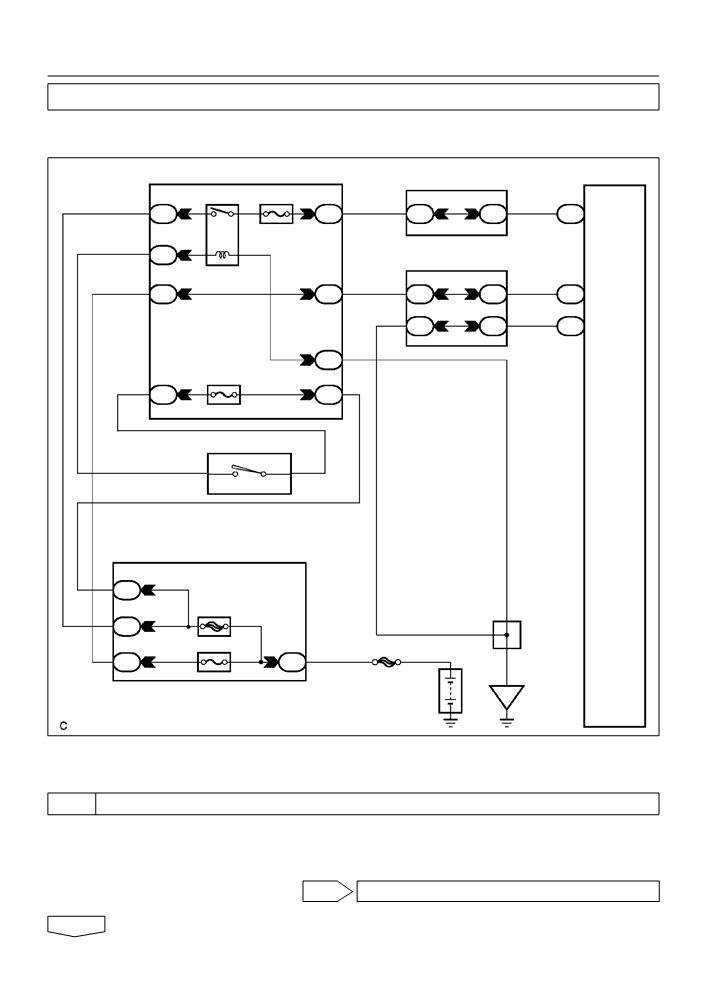

WIRING DIAGRAM

Combination Meter

Instrument Panel J/B

RH J/B

1

IG1 Relay GAUGE

2

22

16

4

IA

IG

3B

3B

C9

IG1

W

5

3

R-W

R-W

2

IF

B-Y

1

2

Center J/B

7

4

20

19

5

IC

IL

4C

4C

C9

+B

L-W

L-W

L-W

21

18

2

4B

4B

C9

POWER

W-B

EARTH

4

IF

W-B

12

AM1

1

IF

IB

W

I10 Ignition Switch

W-B

2

1

IG1

AM1

W

Engine Room J/B, R/B

1

1C

1

ALT

A

2

1

1D

A

J6

DOME

1

J/C

FL MAIN

2

1

1

1A

B

Battery

IE

I32767

INSPECTION PROCEDERE

1

CHECK FUSE

(a) Check that continuity exists of DOME fuse.

(b) Check that continuity exists of GAUGE fuse.

(c)

Check that continuity exists of AM1 fuse.

NG REPLACE FUSE

OK

05-649

DIAGNOSTICS

- COMBINATION METER

2

INSPECT COMBINATION METER ASSY

(a) Check continuity.

(1)

Disconnect the ”C9” connector from combination

meter assy.

(2)

Check continuity between terminal C9-2 of com-

bination meter assy connector and body ground.

OK: Continuity exists

POWER

EARTH

I32115

(b) Check voltage.

(1)

Disconnect the ”C9” connector from combination

meter assy.

(2)

Measure voltage between terminal C9-5 of com-

bination meter assy connector and body ground.

Voltage: 10 - 14 V

(3)

Turn the ignition switch to ON.

(4)

Measure voltage between terminal C9-4 of com-

IG1

+B

I32115

bination meter assy connector and body ground.

Voltage: 10 - 14 V

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK AND REPLACE COMBINATION METER ASSY

05-640

DIAGNOSTICS

- COMBINATION METER

057KC-02

LOCATION

Combination Meter

Brake Fluid Level Warning Switch

Fuel Sender Gauge

Rear Door Courtesy

Switch

Front Door Courtesy Switch

Engine Room J/B, R/B

F DOME Fuse

I32723

05-641

DIAGNOSTICS

- COMBINATION METER

ECM

Passenger Seat Belt Warning

Light Assembly

Key Unlock Warning

Switch

RH J/B

Transmission Control Switch

Center J/B

Parking Brake Switch

Instrument Panel J/B

F GAUGE Fuse

Front Seat Belt Inner Belt

F AM1 Fuse

(Passenger’s)

Separate Type Front Seat

Cushion Pad

Front Seat Belt Inner

Belt (Driver’s)

I32724