Toyota Corolla (2004+). Manual - part 31

41-83

MANUAL TRANSMISSION/TRANSAXLE

- OUTPUT SHAFT ASSY (C59)

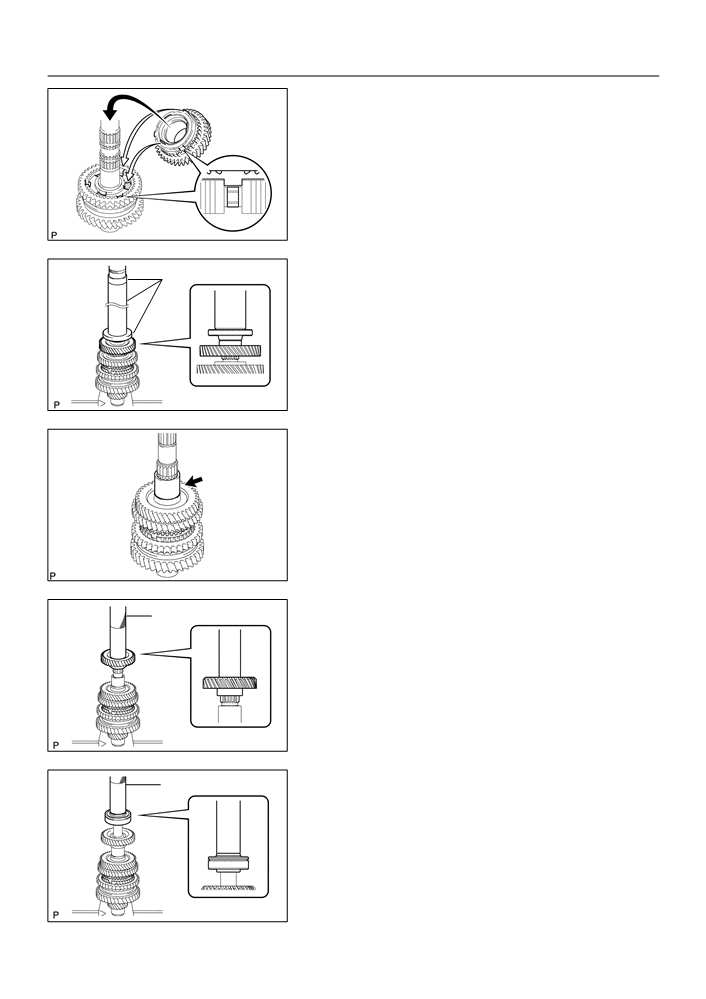

34. INSTALL 2ND GEAR

(a) Coat the 2nd gear with gear oil, install it to the output

shaft.

NOTICE:

Fit the synchronizer inner ring claws into the slots in the

transmission clutch hub No.1.

C95326

35. INSTALL 3RD DRIVEN GEAR

SST

(a) Using SST and a press, install the 3rd driven gear to the

output shaft.

SST

09309-36100 (09309-03610), 09608-00071,

09950-60010 (09951-00450)

C94310

36. INSTALL OUTPUT GEAR SPACER

(a) Install the output gear spacer to the output shaft.

C68005

37. INSTALL 4TH DRIVEN GEAR

SST

(a) Using SST and a press, install 4th driven gear to the out-

put shaft.

SST

09612-22011

C94311

38. INSTALL OUTPUT SHAFT REAR BEARING

SST

(a) Using SST and a press, install output shaft rear bearing

to the output shaft.

SST

09612-22011

C94312

41-84

MANUAL TRANSMISSION/TRANSAXLE

- OUTPUT SHAFT ASSY (C59)

39. INSPECT 2ND GEAR RADIAL CLEARANCE

(a) Using a dial indicator, measure the 2nd gear radial clear-

ance.

Standard clearance:

Bearing

Clearance: mm (in.)

KOYO made

0.015 - 0.058 (0.0006 - 0.0023)

NSK made

0.015 - 0.056 (0.0006 - 0.0022)

If the clearance is out of specification, replace the 2nd gear

C68254

needle roller bearing.

40. INSPECT 1ST GEAR RADIAL CLEARANCE

(a) Using a dial indicator, measure the 1st gear radial clear-

ance.

Standard clearance:

Bearing

Clearance: mm (in.)

KOYO made

0.015 - 0.058 (0.0006 - 0.0023)

NSK made

0.015 - 0.056 (0.0006 - 0.0022)

If the clearance is out of specification, replace the 1st gear

C68309

needle roller bearing.

41. INSPECT 2ND GEAR THRUST CLEARANCE

(a) Using a dial indicator, measure the 2nd gear thrust clear-

ance.

Standard clearance:

0.10 - 0.45 mm (0.0039 - 0.0177 in.)

C68312

42. INSPECT 1ST GEAR THRUST CLEARANCE

(a) Using a feeler gauge, measure the 1st gear thrust clear-

ance.

Standard clearance:

0.10 - 0.40 mm (0.0039 - 0.0157 in.)

C68252

41-17

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY

4107D-02

REPLACEMENT

HINT:

COMPONENTS: See page 41-15

1.

PLACE FRONT WHEELS FACING STRAIGHT AHEAD

2.

REMOVE FRONT WHEELS

3.

REMOVE ENGINE UNDER COVER LH

4.

REMOVE ENGINE UNDER COVER RH

5.

REMOVE EXHAUST PIPE (See page 15-2)

6.

DRAIN TRANSAXLE OIL

7.

REMOVE HOOD SUB-ASSY

8.

REMOVE CYLINDER HEAD COVER NO.2

9.

REMOVE AIR CLEANER ASSY

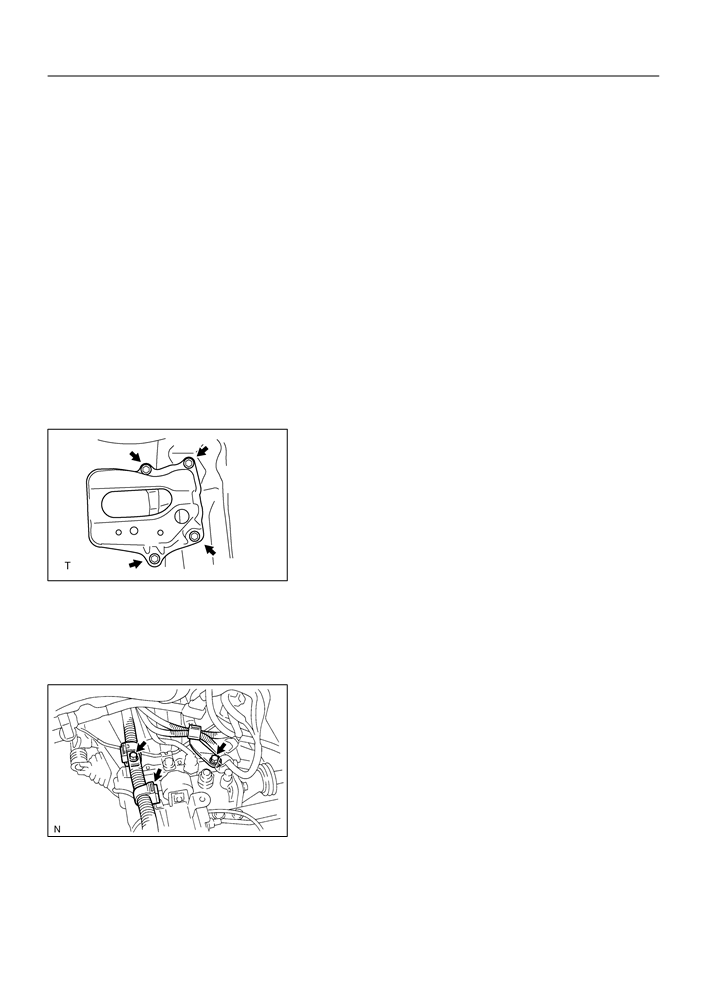

10. REMOVE BATTERY CLAMP SUB-ASSY

11. REMOVE BATTERY

12. REMOVE BATTERY TRAY

13. REMOVE BATTERY CARRIER

(a) Remove the 4 bolts and battery carrier.

C80159

14. REMOVE CRUISE CONTROL ACTUATOR ASSY (W/ CRUISE CONTROL) (See page 82-4)

15. DISCONNECT WIRE HARNESS

(a) Disconnect the wire harness clamp.

(b) Remove the 2 bolts and disconnect the 2 wire harness

brackets.

C95746

41-18

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY

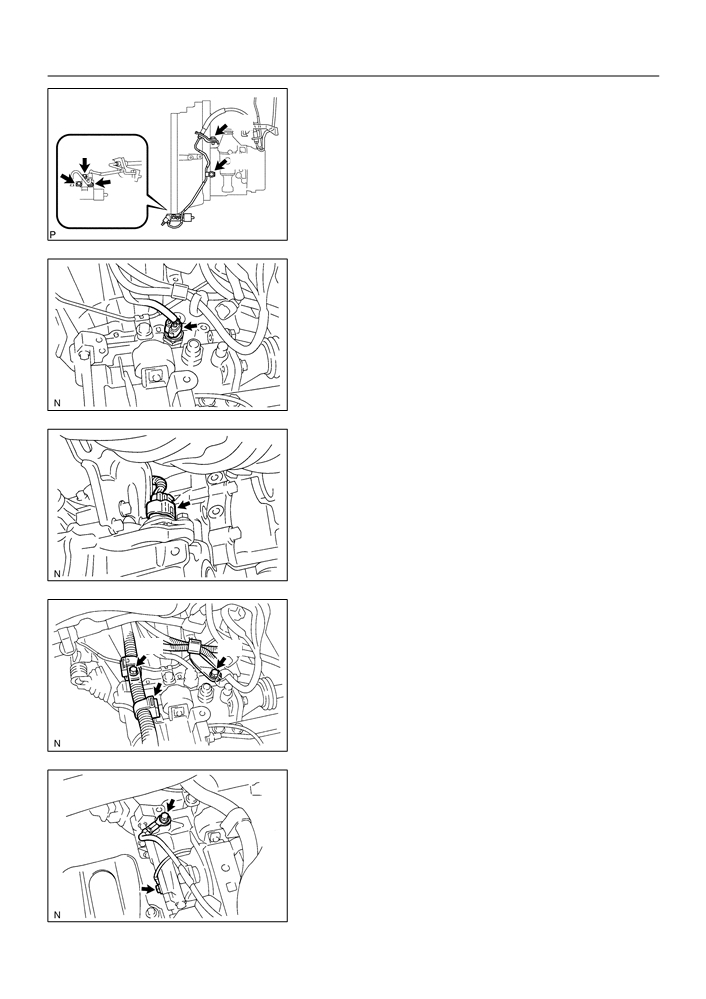

(c)

Remove the 2 bolts and 2 ground cables.

C95747

16. DISCONNECT CONNECTOR

(a) Disconnect the back-up lamp switch connector.

D11552

(b) w/o ABS:

Disconnect the speed sensor connector.

D11558

17. SEPARATE CLUTCH RELEASE CYLINDER ASSY

(a) Remove the 5 bolts, separate the release cylinder assy

with clutch piping from the transaxle.

D26730

18. SEPARATE FLOOR SHIFT CABLE TRANSMISSION

CONTROL SHIFT

(a) Remove the clip, washer and disconnect the shift cable

from the transaxle.

(b) Remove the clip and disconnect the shift cable from the

bracket.

D26696

41-19

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY

19. SEPARATE FLOOR SHIFT CABLE TRANSMISSION

CONTROL SELECT

(a) Remove the clip, washer and disconnect the select cable

from the transaxle.

(b) Remove the clip and disconnect the select cable from the

bracket.

D26768

20. REMOVE STARTER ASSY

(a) Remove the nut and disconnect the starter wire.

(b) Disconnect the connector.

(c)

Remove the 2 bolts and starter assy.

D11561

21. SEPARATE STEERING INTERMEDIATE SHAFT (See page 51-18)

22. REMOVE FRONT DRIVE SHAFT ASSY LH (See page 30-6)

SST

09520-01010, 09520-24010 (09520-32040)

23. REMOVE FRONT DRIVE SHAFT ASSY RH

HINT:

Remove the RH side by the same procedures as LH side.

SST

09520-01010, 09520-24010 (09520-32040)

24. SEPARATE RETURN TUBE SUB-ASSY (See page 51-18)

SST

09023-12700

25. SEPARATE PRESSURE FEED TUBE ASSY (See page 51-18)

26. SUSPEND ENGINE ASSY

(a) Remove the 2 PCV hoses.

(b) Install the 2 hangers in the correct direction.

Parts No.:

Engine hanger: 12281-22021

No.1 engine hanger: 12281-15040

Bolt: 91512-B1016

Torque: 38 N m (387 kgf cm, 28 ft lbf)

F16861

(c)

Attach the engine chain hoist to the hangers.

CAUTION:

Do not attempt to hang the engine by hooking the chain to

any other part.

27. REMOVE FRONT SUSPENSION CROSSMEMBER SUB-ASSY (See page 26-13)

28. SUPPORT MANUAL TRANSAXLE ASSY

(a) Support the transaxle with a transmission jack.

41-20

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY

29. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING INSULATOR

(a) Remove the 5 bolts, nut and engine mounting insulator

LH from the body.

D26699

30. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING BRACKET

(a) Remove the 3 bolts and engine mounting bracket LH from

the transaxle.

D26700

31. REMOVE MANUAL TRANSAXLE ASSY

(a) Remove the 6 bolts and transaxle from the engine.

C70065

32. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING BRACKET

(a) Remove the bolt, nut and engine mounting insulator FR

from the engine mounting bracket FR.

(b) Remove the 2 bolts and engine mounting bracket FR from

the transaxle.

C70063

33. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING BRACKET

(a) Remove the bolt and engine mounting insulator RR from

the engine mounting bracket RR.

(b) Remove the 3 bolts and engine mounting bracket RR

from the transaxle.

C70061

41-21

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY

34.

INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

(a)

(b)

BRACKET

(a)

Install the engine mounting bracket RR and 3 bolts to the

transaxle.

Torque: 64 N m (653 kgf cm, 47 ft lbf)

(b)

Install the engine mounting insulator RR and bolt to the

engine mounting bracket RR.

(a)

Torque: 87 N m (888 kgf cm, 64 ft lbf)

C70061

35.

INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

BRACKET

(a)

(a)

Install the engine mounting bracket FR and 2 bolts to the

transaxle.

Torque: 64 N m (653 kgf cm, 47 ft lbf)

(b)

Install the engine mounting insulator FR, bolt and nut to

the engine mounting bracket FR.

(b)

Torque: 52 N m (530 kgf cm, 38 ft lbf)

C70063

36.

INSTALL MANUAL TRANSAXLE ASSY

A

A

(a)

Align the input shaft with the clutch disc and install the

B

transaxle to the engine.

B

(b)

Install the 6 bolts.

Torque:

Bolt A: 64 N m (650 kgf cm, 47 ft lbf)

Bolt B: 47 N m (480 kgf cm, 35 ft lbf)

C

Bolt C: 23 N m (230 kgf cm, 17 ft lbf)

C

C70065

37.

INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

BRACKET

(a)

Install the engine mounting bracket LH to the transaxle

with the 3 bolts.

Torque: 52 N m (530 kgf cm, 38 ft lbf)

D26700

38. INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

A

A

INSULATOR

(a) Install the engine mounting insulator LH with the 5 bolts

and nut.

Torque:

Bolt A: 52 N m (530 kgf cm, 38 ft lbf)

Bolt B: 80 N m (816 kgf cm, 59 ft lbf)

B

A

A

D26699

41-22

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY

39. INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSY (See page 26-13)

SST

09670-00010

40. CONNECT STEERING INTERMEDIATE SHAFT (See page 51-18)

41. INSTALL COLUMN HOLE COVER SILENCER SHEET (See page 51-18)

42. CONNECT RETURN TUBE SUB-ASSY (See page 51-18)

SST

09023-12700

43. CONNECT PRESSURE FEED TUBE ASSY (See page 51-18)

SST

09023-12700

44. INSTALL FRONT DRIVE SHAFT ASSY LH (See page 30-6)

45. INSTALL FRONT DRIVE SHAFT ASSY RH

HINT:

Install the RH side by the same procedures as LH side.

46. INSTALL STARTER ASSY

(a) Install the starter assy and 2 bolts to the transaxle.

(c)

Torque: 37 N m (378 kgf cm, 27 ft lbf)

(b) Connect the starter connector.

(a)

(c)

Install the wire and nut to starter assy.

(b)

Torque: 9.8 N m (100 kgf cm, 87 in. lbf)

(a)

D11561

47. CONNECT FLOOR SHIFT CABLE TRANSMISSION

CONTROL SHIFT

(a) Connect the shift cable end, and install the washer and

clip.

D26696

48. CONNECT FLOOR SHIFT CABLE TRANSMISSION

CONTROL SELECT

(a) Connect the select cable end, and install the washer and

clip.

D26768

41-23

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY

49. CONNECT CLUTCH RELEASE CYLINDER ASSY

(a) Install the release cylinder with the 5 bolts.

A

Torque:

Bolt A: 25 N m (250 kgf cm, 19 ft lbf)

C

A

Bolt B: 12 N m (120 kgf cm, 9 ft lbf)

Bolt C: 5.0 N m (51 kgf cm, 44 in. lbf)

B

B

D26730

50. CONNECT CONNECTOR

(a) Connect the back-up lamp switch connector.

D11552

(b) w/o ABS:

Connect the speed sensor connector.

D11558

51. CONNECT WIRE HARNESS

(a) Install the 2 wire harness clamps to the transaxle with the

2 bolts.

A

B

Torque:

Bolt A: 25.5 N m (260 kgf cm, 19 ft lbf)

Bolt B: 12.8 N m (131 kgf cm, 9 ft lbf)

(1)

Connect the wire harness clamp.

F16859

(b) Install the 2 bolts and 2 ground cables.

Torque: 13 N m (133 kgf cm, 10 ft lbf)

F16860

41-24

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY

52. INSTALL CRUISE CONTROL ACTUATOR ASSY (W/ CRUISE CONTROL) (See page

82-4)

53. INSTALL BATTERY CARRIER

(a) Install the battery carrier and 4 bolts.

Torque: 13 N m (133 kgf cm, 10 ft lbf)

C80159

54.

INSTALL BATTERY TRAY

55.

INSTALL BATTERY

56.

INSTALL BATTERY CLAMP SUB-ASSY

Torque:

Bolt: 5.0 N m (51 kgf cm, 44 in. lbf)

Nut: 3.5 N m (36 kgf cm, 31 in. lbf)

57.

INSTALL AIR CLEANER ASSY

Torque: 7.0 N m (71 kgf cm, 62 in. lbf)

58.

INSTALL CYLINDER HEAD COVER NO.2

Torque: 7.0 N m (71 kgf cm, 62 in. lbf)

59.

INSTALL HOOD SUB-ASSY

Torque: 13 N m (133 kgf cm, 10 ft lbf)

60.

INSPECT HOOD SUB-ASSY

61.

ADJUST HOOD SUB-ASSY (See page 75-1)

62.

ADD TRANSAXLE OIL (See page 41-2)

63.

INSPECT TRANSAXLE OIL (See page 41-2)

64.

BLEED POWER STEERING FLUID (See page 51-3)

65.

INSTALL FRONT WHEELS

Torque: 103 N m (1,050 kgf cm, 76 ft lbf)

66.

PLACE FRONT WHEELS FACING STRAIGHT AHEAD

67.

INSTALL EXHAUST PIPE (See page 15-2)

68.

INSTALL ENGINE UNDER COVER LH

69.

INSTALL ENGINE UNDER COVER RH

70.

INSPECT FRONT WHEEL ALIGNMENT (See page 26-5)

71.

CHECK ABS SPEED SENSOR SIGNAL (See page 05-297)

41-91

MANUAL TRANSMISSION/TRANSAXLE

- SHIFT & SELECT LEVER SHAFT ASSY (C59)

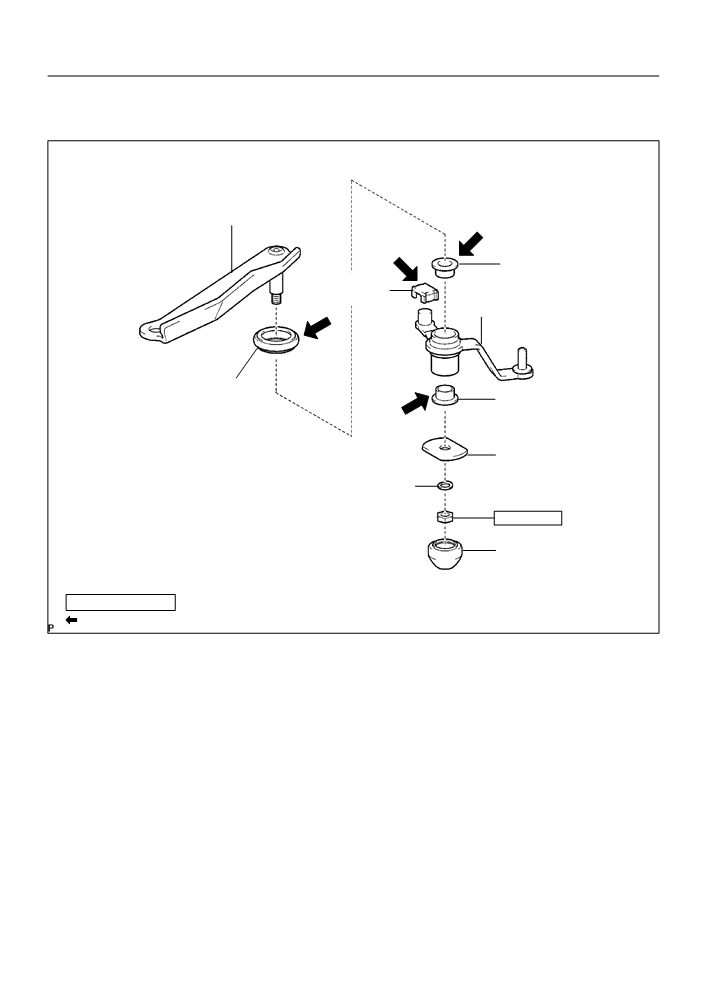

SHIFT & SELECT LEVER SHAFT ASSY (C59)

4107M-01

COMPONENTS

Selecting Bellcrank Support

Selecting Bellcrank

No.2 Bush

Control Shift

Lever Bush

Selecting Bellcrank No.2

Selecting Bellcrank

Selecting Bellcrank

Dust Cover No.2

No.2 Bush

Selecting Bellcrank

No.2 Plate Washer

Washer

11.8 (120, 9)

Selecting Bellcrank

Dust Cover No.1

Nm (kgfcm, ftlbf)

: Specified torque

Apply MP grease

C94578

41-92

MANUAL TRANSMISSION/TRANSAXLE

- SHIFT & SELECT LEVER SHAFT ASSY (C59)

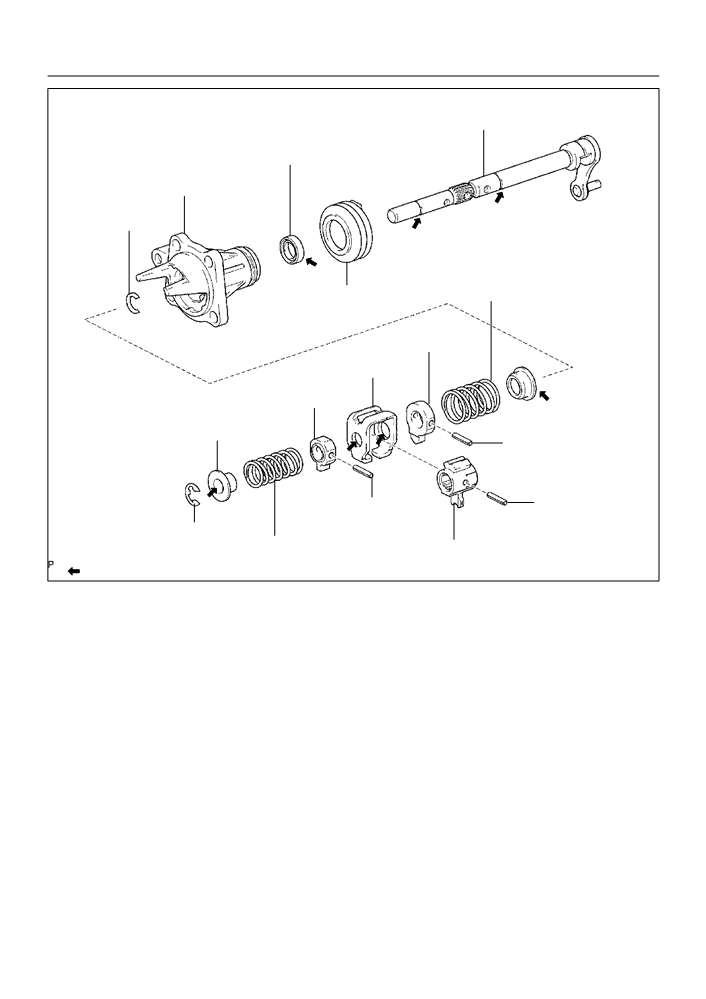

Shift & Select Lever Shaft

_ Control Shaft Cover Oil Seal

Control Shaft Cover

Snap Ring

Shift & Select Lever Shaft Boot

Compression Spring

Select Inner Lever

Shift Inter Lock Plate

Shift Lever Inner No.2

Select Spring Seat No.2

Slotted Spring Pin

Slotted Spring Pin

Slotted Spring Pin

E-ring

Compression Spring

Shift Inner Lever No.2

_ Non-reusable part

Apply MP grease

D12109

41-93

MANUAL TRANSMISSION/TRANSAXLE

- SHIFT & SELECT LEVER SHAFT ASSY (C59)

4107N-01

OVERHAUL

1.

REMOVE CONTROL SHIFT LEVER BUSH

(a) Remove the control shift lever bush from the selecting

bellcrank assy.

C80760

2.

REMOVE SELECTING BELLCRANK DUST COVER

NO.1

(a) Remove the selecting bellcrank dust cover No.1 from the

selecting bellcrank assy.

C80761

3.

REMOVE SELECTING BELL CRANK NO.2

(a) Remove the nut, spring washer and selecting bellcrank

No.2 plate washer.

(b) Remove the selecting bellcrank No.2 from the selecting

bellcrank support.

C80762

4.

REMOVE SELECTING BELLCRANK DUST COVER

NO.2

(a) Remove the selecting bellcrank dust cover No.2 from the

selecting bellcrank No.2.

C80763

41-94

MANUAL TRANSMISSION/TRANSAXLE

- SHIFT & SELECT LEVER SHAFT ASSY (C59)

5.

REMOVE SELECTING BELLCRANK NO.2 BUSH

(a) Remove the 2 selecting bellcrank No.2 bushes from the

selecting bellcrank No.2.

C80571

6.

REMOVE SELECT SPRING SEAT NO.2

(a) Using a screwdriver, remove the E-ring, select spring

seat No.2 and select return spring No.2 from the shift &

select lever shaft.

C80572

7.

REMOVE SHIFT LEVER INNER NO.2

(a) Using a pin punch (f 5 mm) and a hammer, remove the

slotted pin and shift lever inner No.2 from the shift & select

lever shaft.

HINT:

Make sure the orientation of the shift lever inner No.2.

C80573

8.

REMOVE SHIFT LEVER INNER NO.1

(a) Using a pin punch (f 5 mm) and a hammer, remove the

slotted pin, shift lever inner No.1 and shift inter lock plate

from the shift & select lever shaft.

HINT:

Make sure the orientation of the shift lever inner No.1.

C80574

9.

REMOVE SELECT INNER LEVER

(a) Using a pin punch (f 5 mm) and a hammer, remove the

slotted pin, select inner lever, select return spring No.1

and select return spring seat No.1.

HINT:

Make sure the orientation of the select inner lever.

C80575

41-95

MANUAL TRANSMISSION/TRANSAXLE

- SHIFT & SELECT LEVER SHAFT ASSY (C59)

10. REMOVE CONTROL SHAFT COVER

(a) Using 2 screwdrivers and a hammer, tap out the snap

ring.

(b) Remove the control shaft cover and shift & select lever

shaft dust boot.

C95740

11. REMOVE CONTROL SHAFT COVER OIL SEAL

(a) Using a screwdriver, remove the control shaft cover oil

seal from the control shaft cover.

C95742

12. INSTALL CONTROL SHAFT COVER OIL SEAL

SST

(a) Using SST and a hammer, install a new control shaft cov-

er oil seal to the control shaft cover.

SST

09950-60010 (09951-00220), 09950-70010

(09951-07100)

Drive in depth: 0.7

0.5 mm (0.0276

0.0197 in.)

(b) Coat the lip of control shaft cover oil seal with MP grease.

C94255

13. INSTALL CONTROL SHAFT COVER

(a) Coat the shift & select lever shaft boot with MP grease,

install it to the control shaft cover.

(b) Install the control shaft cover to the shift & select lever.

HINT:

Install the dust boot with the projection up and the hole side

down.

(c)

Coat the shift & select lever shaft with MP grease.

C94256

(d) Using a brass bar and a hammer, tap in the snap ring to

the shift & select lever shaft.

C95742