SsangYong Rexton. Service manual - part 502

FRONT BRAKE 4B-13

SSANGYONG Y200

YAD4B240

YAD4B250

YAD4B260

UNIT REPAIR

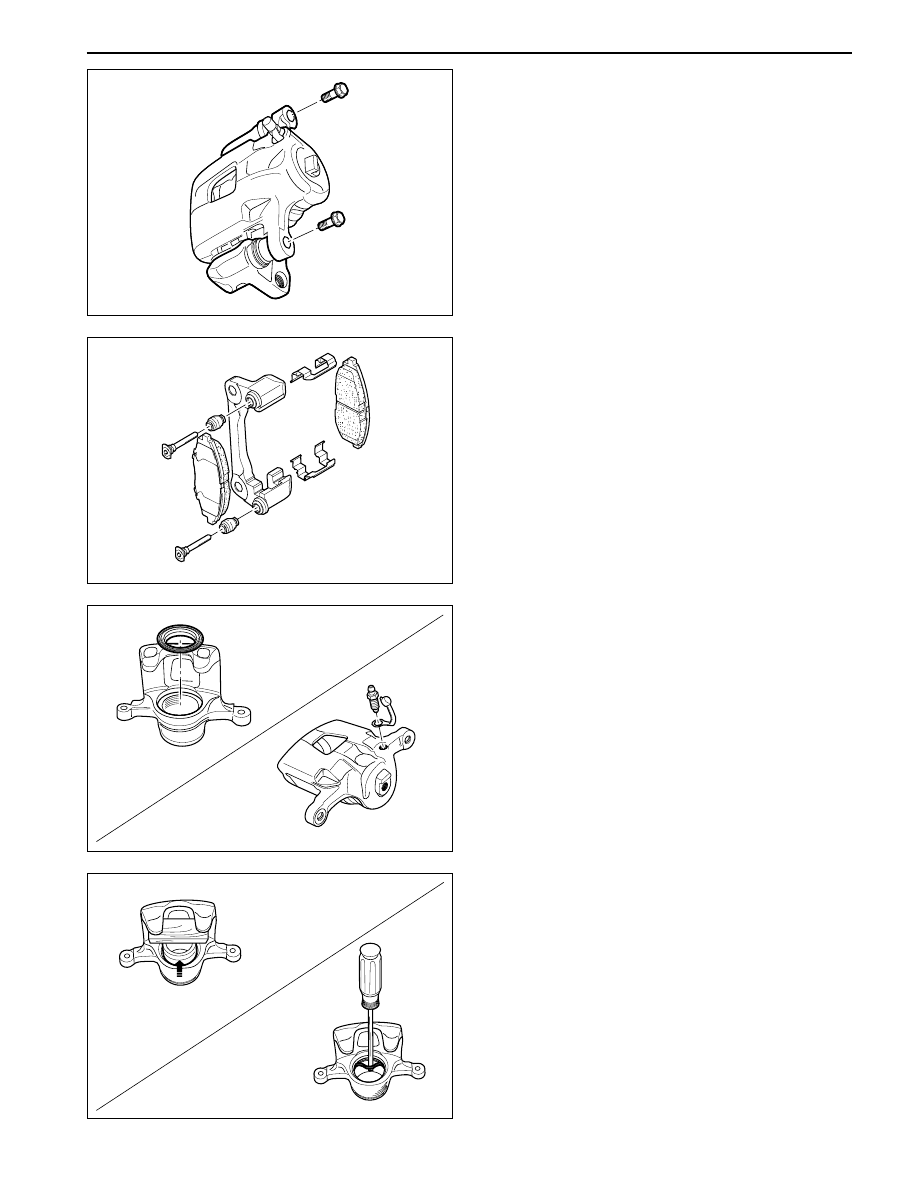

BRAKE CALIPER

Disassembly Procedure

1. Remove the caliper assembly.

2. Separate the cylinder assembly and carrier.

•

Remove the guide rod bolt.

•

Separate the cylinder assembly and carrier.

3. Disassemble the carrier.

•

Remove the pad.

•

Remove the spring.

•

Remove the guide rod and the boot.

4. Remove the cylinder assembly.

•

Remove the bleeder plug.

•

Remove the bleeder plug cap.

•

Remove the piston boot.

YAD4B270

•

Using the compressed air, blow out the piston

from housing.

Notice: Do not face in the direction of removing.

•

Remove the piston.

•

Remove the piston seal.