SsangYong Rexton. Service manual - part 493

SSANGYONG Y200

4A-2 BRAKE SYSTEM

DESCRIPTION AND OPERATION

BRAKING SYSTEM TESTING

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake

performance cannot be made if the roadway is wet,

greasy or covered with loose dirt which can cause tires

not to grip the road unequally. Testing also will be

inaccurate on a crowned roadway because the wheels

tend to bounce.

Test the brakes at different vehicle speeds with both

light-and heavy-pedal pressure; however, avoid locking

the brakes and sliding the tires. Locked brakes and

sliding tires do not indicate brake efficiency since

heavily braked but turning wheels will stop the vehicle

in less distance than locked brakes. More tire-to-road

friction is present with a heavily braked, turning tire

than with a sliding tire.

There are three major external conditions that affect

brake performance:

•

Tires having unequal contact and grip of the road

will cause unequal braking. Tires must be equally

inflated and the tread pattern of the right and the

left tires must be approximately equal.

•

Unequal loading of the vehicle can affect the brake

performance since the most heavily loaded wheels

require more braking power and thus more braking

effort than the others.

•

Misalignment of the wheels, particularly conditions

of excessive camber and caster, will cause the

brakes to pull to one side.

HYDRAULIC BRAKE SYSTEM

BRAKE PEDAL

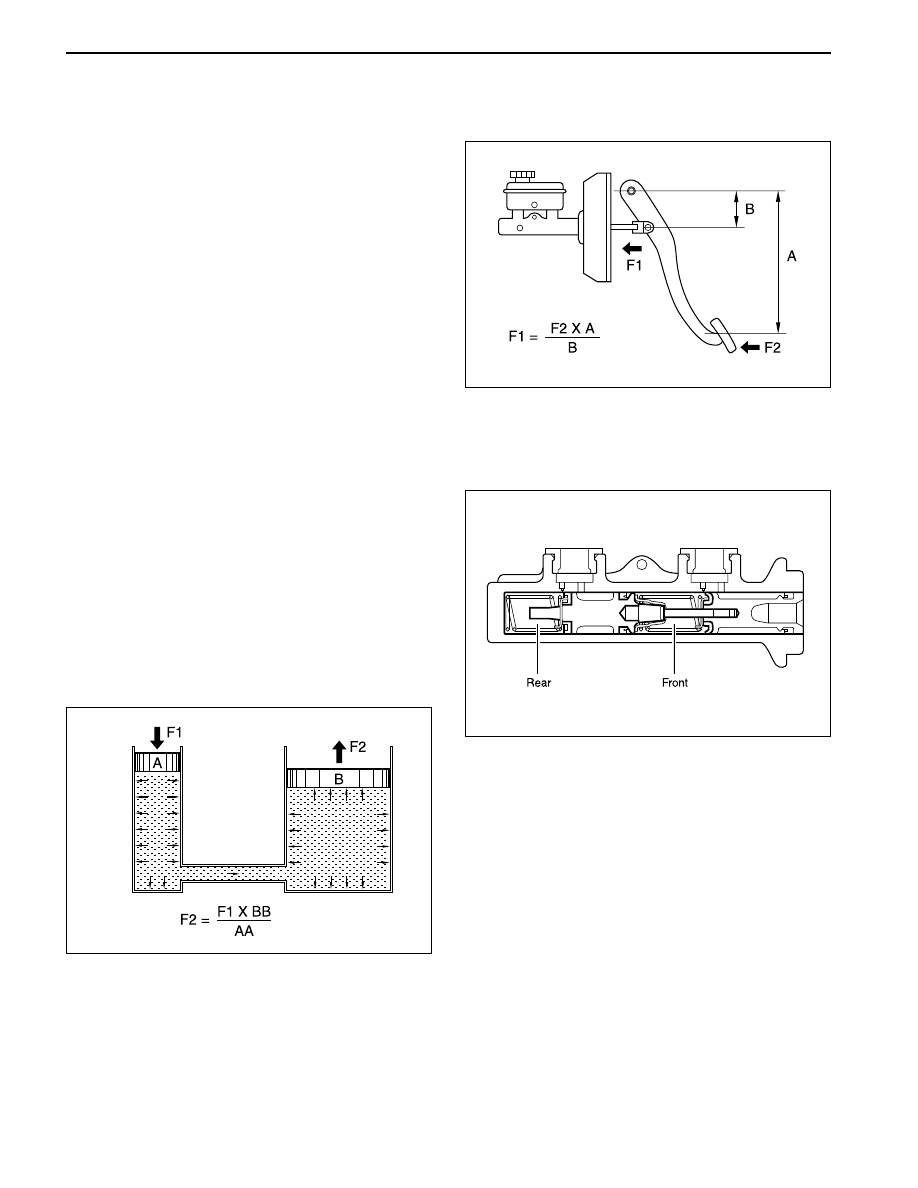

YAD4A010

This system uses the principle of the leverage and

PASCAL’s. When you pushes the brake pedal, the

pressure by adapting the pedal increases through the

power booster and delivers it into the master cylinder

to generate hydraulic pressure.

Hydraulic pressure generated by the master cylinder

delivers to the caliper through the brake pipe or hose.

This hydraulic pressure allows the caliper pad to push

the disc plate. Thus it generates the braking forces.

YAD4A020

Brake pedal uses the principle of the leverage and

increases the pressure into the master cylinder in order

to generate the braking forces.

MASTER CYLINDER

The master cylinder is designed for use in a diagonally

split system. One front and one diagonally opposite

rear brakes are served by the primary piston. The

opposite front and rear brakes are served by the

secondary piston.

The master cylinder incorporates the functions of the

standard dual master cylinder, plus a low fluid level

indicator and the proportioning valves in the non-

antilock braking system. The proportioning valves limit

the outlet pressures to the rear brakes after a

predetermined master cylinder pressure has been

reached. The brake master cylinder sensor is attached

under the body of the plastic brake master cylinder

reservoir.

YAD4A030