SsangYong Rexton. Service manual - part 441

SSANGYONG Y200

1F2-90 M161 ENGINE CONTROLS

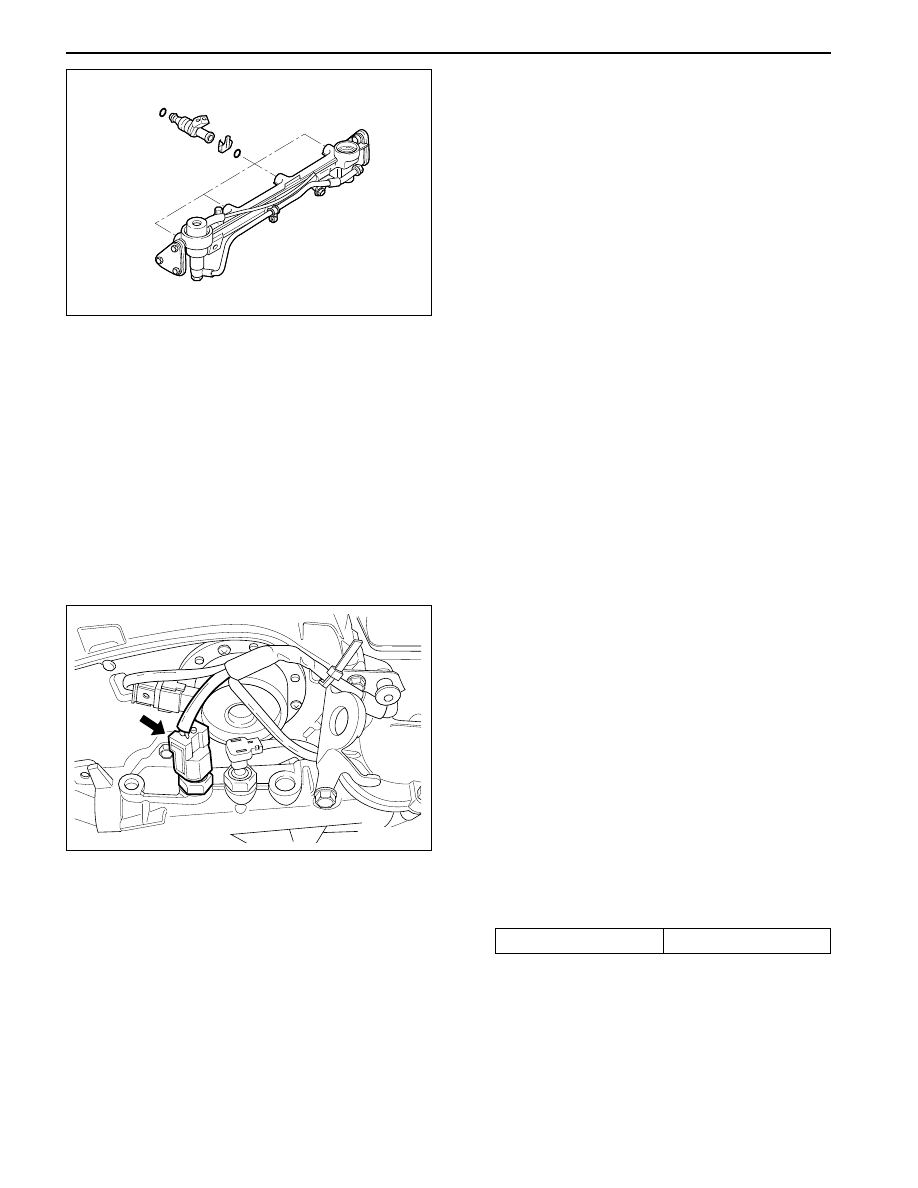

Notice: Before removal, the fuel rail assembly may

be cleaned with a spray-type cleaner, following

package instructions. Do not immerse the fuel rails

in liquid cleaning solvent. Use care in removing

the fuel rail assembly to prevent damage to the

electrical connectors and injector spray tips.

Prevent dirt and other contaminants from entering

open lines and passages. Fittings should be

capped and holes plugged during service.

Important: If an injector becomes separated from

the rail and remains in the cylinder head, replace

the injector O-ring seals and the retaining clip.

12. Remove the injectors and the fuel rail carefully.

13. Remove the fuel injector retainer clips.

14. Remove the fuel injectors by pulling them down

and out.

15. Discard the fuel injector O-rings.

16. Lubricate the new fuel injector O-rings with engine

oil. Install the new O-rings on the fuel injectors.

17. Perform a leak check of the fuel rail and fuel

injectors.

18. Installation should follow the removal procedure

in the reverse order.

YAA1F770

YAA1F780

ENGINE COOLANT TEMPERATURE

SENSOR

Removal and Installation Procedure

1. Relieve the coolant system pressure.

2. Disconnect the negative battery cable.

3. Disconnect the engine coolant temperature sensor

connector.

Notice: Take care when handling the engine

coolant temperature sensor. Damage to the sensor

will affect the proper operation of the fuel injection

system.

4. Remove the engine coolant temperature sensor

from the pump hosing.

Installation Notice

Tightening Torque

30 N•m (22 lb-ft)

5. Installation should follow the removal procedure

in the reverse order.