SsangYong Rexton. Service manual - part 440

SSANGYONG Y200

1F2-86 M161 ENGINE CONTROLS

YAA1F550

YAA1F190

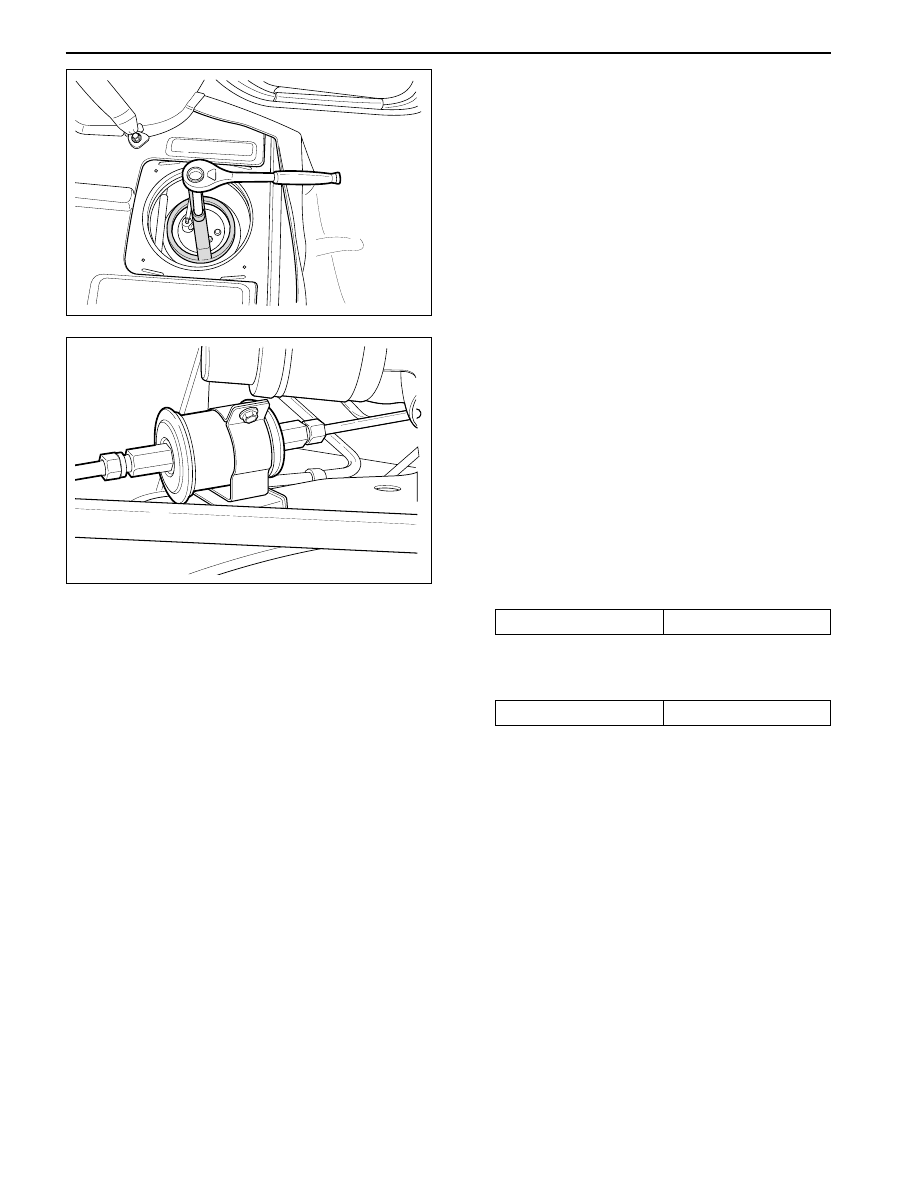

8. Using the fuel tank cap wrench 661 589 00 46 00,

remove the locking cap.

9. Remove the pump from the fuel tank.

Notice: Check the condition of the seal and

replace if necessary. Drain the fuel before

removing the pump.

10. Perform an operational check of the fuel pump.

11. Installation should follow the removal procedure

in the reverse order.

FUEL FILTER

Removal and Installation Procedure

1. Disconnect the negative battery cable.

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury

or fire, it is necessary to relieve the fuel system

pressure before disconnecting the fuel lines.

2. Relieve the fuel system pressure. Refer to “Dis-

charging the Pressure in Fuel System” in this sec-

tion.

3. Disconnect the fuel lines from the fuel filter.

Installation Notice

Tightening Torque

28 N•m (21 lb-ft)

4. Remove the fuel filter mounting bracket bolt .

Installation Notice

Tightening Torque

6 N•m (53 lb-in)

Notice: Place the fuel pump pad. There may be

acorrosion due to the contact between the fuel filter

and the bracket.

5. Remove the fuel filter.

6. Install the fuel filter.

7. Perform a leak test of the fuel filter.

8. Installation should follow the removal procedure

in the reverse order.