SsangYong Rexton. Service manual - part 432

SSANGYONG Y200

1F2-48 M161 ENGINE CONTROLS

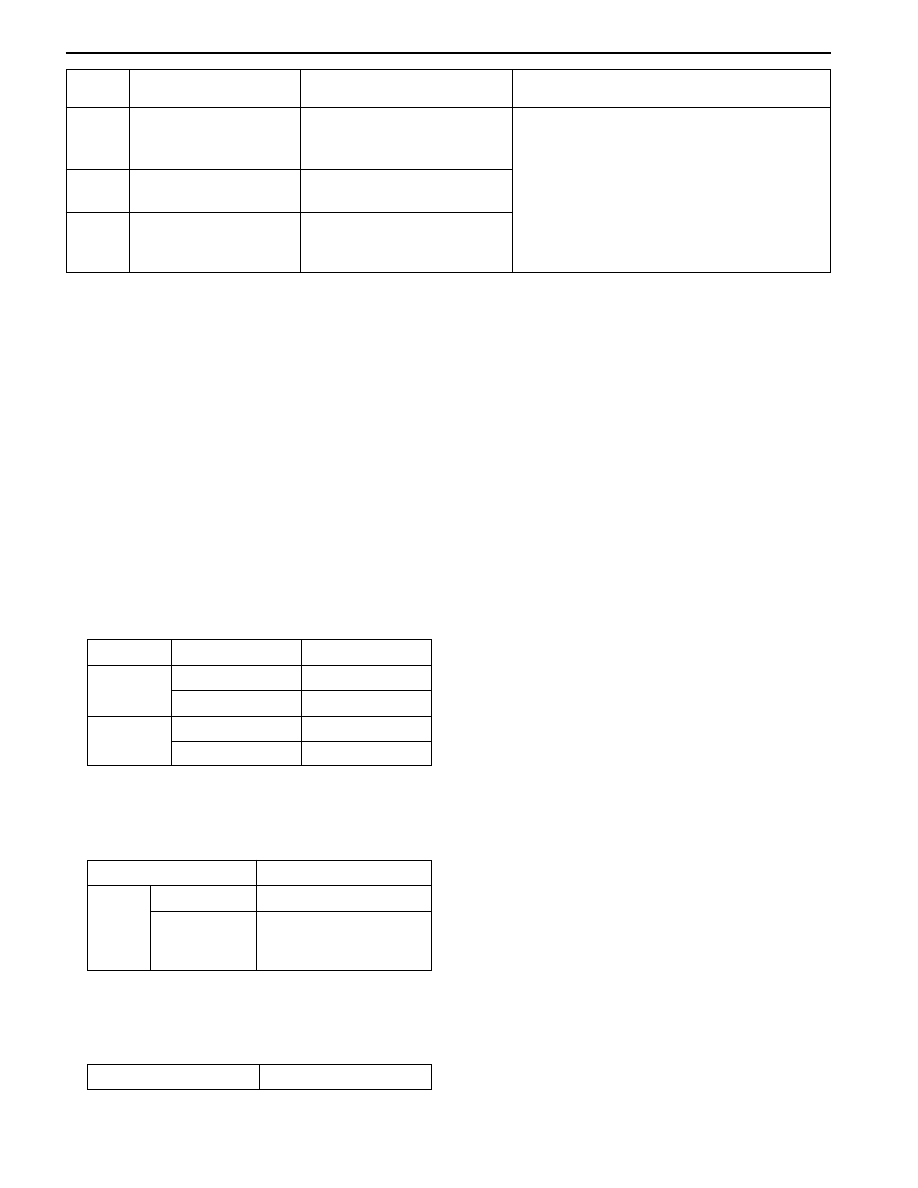

Failure

Code

Description

Trouble Area

Maintenance Hint

Throttle position sensor

1 not plausible with

Throttle position sensor 2

High permanent throttle

signal

Mass air flow sensor

and throttle position

sensor failure

When difference between

TPS 1 and TPS 2

When failure of wiring

harness or actuator

When difference between

MAF and TPS signal

•

Monitoring the actual values through

scan tool

•

Inspection the ECM pin 84, 85, 87, 112,

67, 68 about short circuit or open with

bad contact

•

Inspection the throttle valve actuator

•

Inspection the ECM

126

127

185

Circuit Description

The ECM supplies a 5 volt reference signal and a ground to the TP sensor. The TP sensor sends a voltage signal

back to the ECM relative to the throttle plate opening. The volt age signal will vary from approximately 0.3 ~ 0.9

volts at closed throttle, to over 4.0 ~ 4.6 volts at Wide Open Throttle (WOT).

The TP sensors serve for engine load control according to the drive pedal command. Load adjustments independent

of the drive pedal command can be implemented; such functions are, for instance, idle control, speed control,

drive slip control, load shock damping, and similar functions .

When the actuator current fails , the throttle valve is returned to emergency operating position by a spring. The

throttle valve position, there by the actuator drive position check back is provided by two potentiometers. The

motor positions the throttle valve against the return spring force. Motor and return spring are two separate energy

sources . Each of them is able to position the throttle valve in emergency position alone. Throttle valve position

check back and monitoring is provided by two actual value potentiometers connected to the engine control

electronics.

Specified Value

< 10

Ω

Throttle Actuator Inspection

1. Turn the ignition switch to “ON” position.

2. Measure the TPS 1 signal volt age at the ECM pin No. 87 and TPS 2 signal volt age at the ECM pin No. 85.

TPS 1

TPS 2

Specified Value

Pedal Position

0.3 ~ 0.9 v

4.0 ~ 4.6 v

4.0 ~ 4.6 v

0.3 ~ 0.9 v

Closed

Opened

Closed

Opened

Throttle Actuator DC Motor Inspection

1. Turn the ignition switch to “ON” position.

2. Measure the signal volt age between the ECM pin No. 67 and No. 68.

Throttle Actuator DC Motor Resistance

1. Turn the ignition switch to “OFF” position.

2. Measure the resistance between the ECM pin No. 67 and No. 68.

Ignition “ON”

Idling

Engine

Status

Specified Value

Application

0.8 ~ 2.3 v

1.0 ~ 2.5 v

(Coolant temperature is

over 70° C)