SsangYong Rexton. Service manual - part 421

SSANGYONG Y200

1F1-102 M162 ENGINE CONTROLS

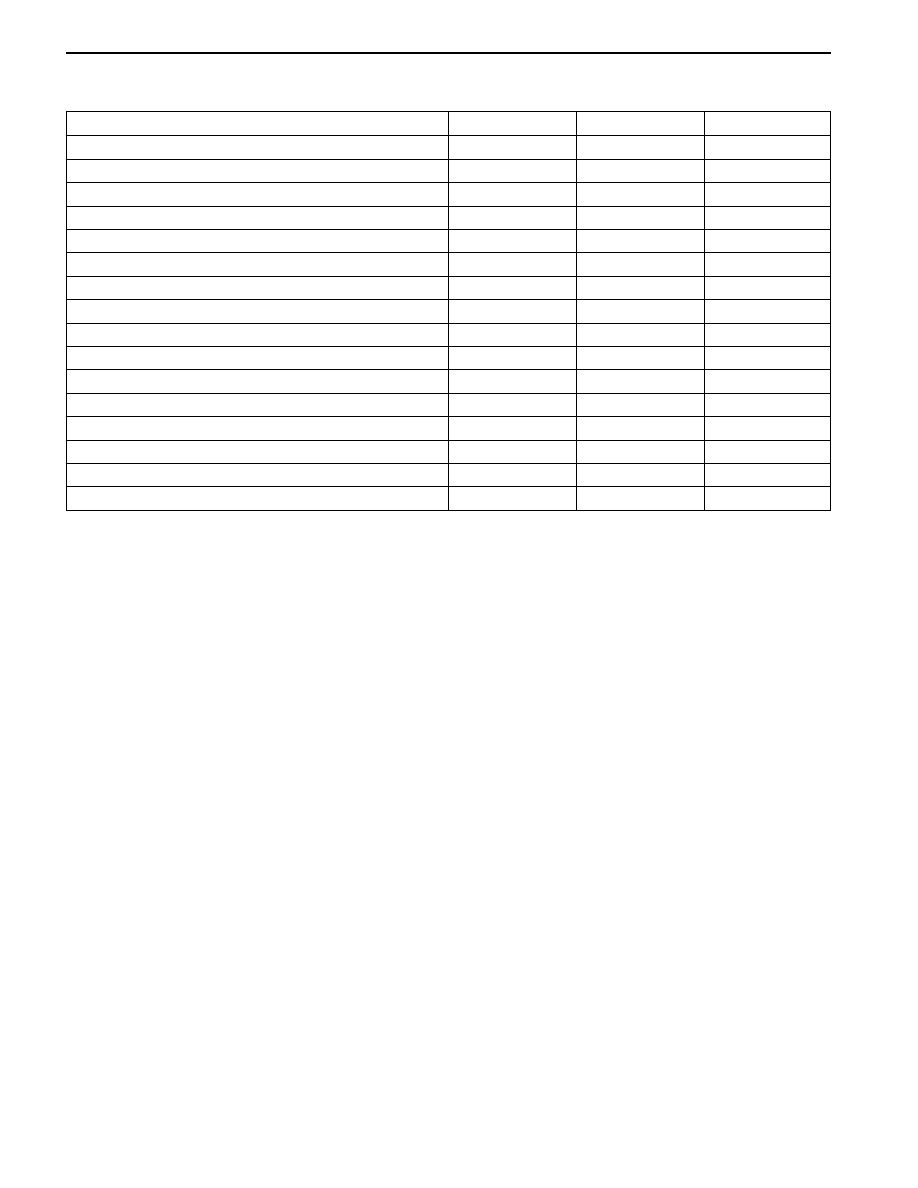

FASTENER TIGHTENING SPECIFICATIONS

Application

Camshaft Position Sensor Retaining Bolts

Canister Mounting Bolts

Coolant Temperature Sensor

Crankshaft Position Sensor Retaining Bolt

Engine Control Module (ECM) Mounting Bracket Nuts

Fuel Filter Mounting Bracket Bolt

Fuel Filter Lines

Fuel Pressure Test Connector

Fuel Rail Assembly Bolts

Fuel Return And Supply Lines

Fuel Tank Retaining Nuts

Intake Air Duct Mounting Bolts

Knock Sensor Mounting Bolt

Oxygen Sensor

Pedal Position Censor Mounting Bolts And Nut

Throttle Body Bolts

N • m

10

6

30

10

10

6

28

25

25

23

38

9

25

55

6

12

Lb-Ft

-

-

22

-

-

-

21

18

18

17

28

-

18

41

-

-

Lb-In

89

53

-

89

89

53

-

-

-

-

-

80

-

-

53

106