SsangYong Rexton. Service manual - part 414

M162 ENGINE CONTROLS 1F1-73

SSANGYONG Y200

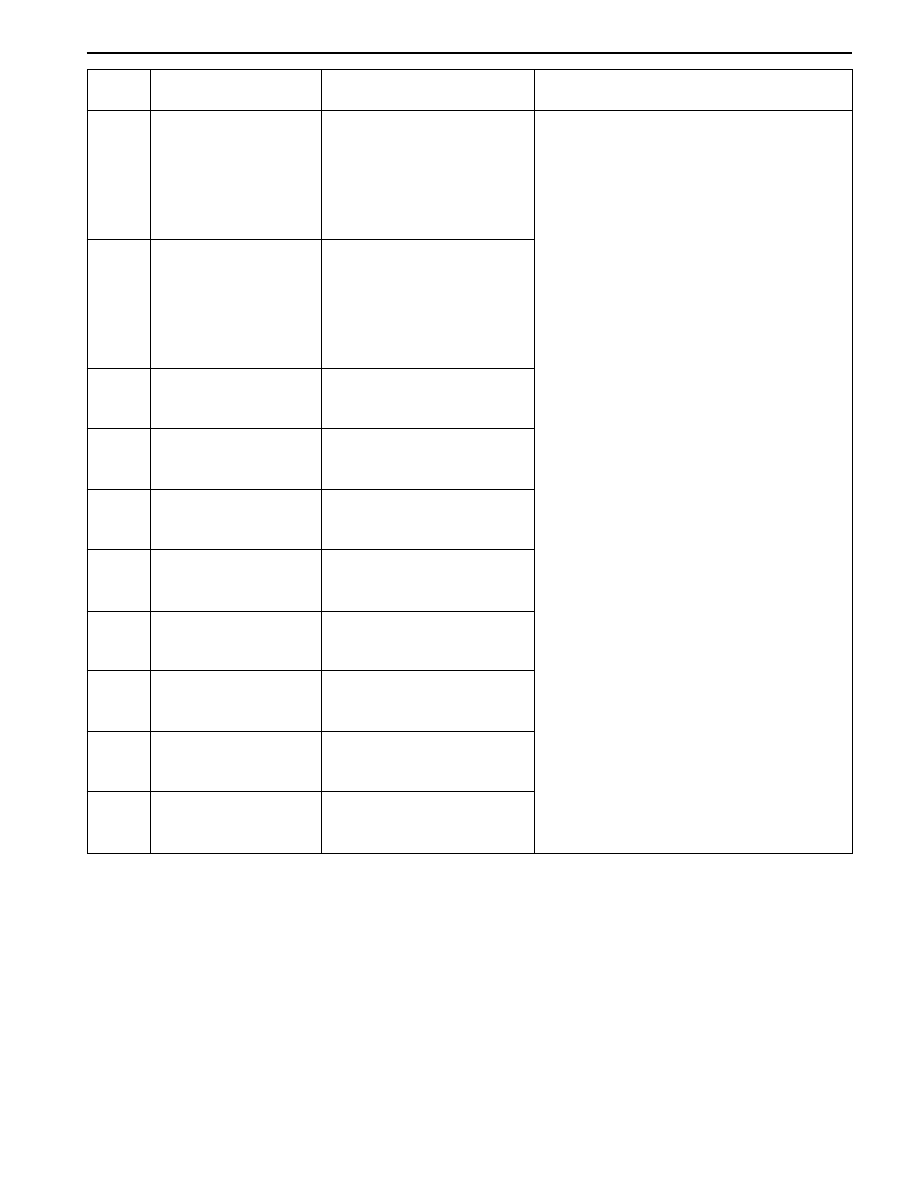

Bank 1 system short

term fuel trim

adaptation below lean

threshold

Bank 1 system short

term fuel trim

adaptation above rich

threshold

Bank 1 system short

term fuel trim at rich

stop

Bank 1 system short

term fuel trim at lean

stop

Bank 1 system idle

adaptation failure

(above rich threshold)

Bank 1 system idle

adaptation failure

(below rich threshold)

Bank 1 system learning

control failure (rich, low

load)

Bank 1 system learning

control failure (lean, low

load)

Bank 1 system learning

control failure (rich, high

load)

Bank 1 system learning

control failure (rich, low

load)

Failure

Code

Description

Trouble Area

Maintenance Hint

When recognition the value

less than nominal control

threshold, it means that when

big deviation in control range

of adaptation values through

fuel and air mixture formation

When recognition the value

more than nominal control

threshold, it means that when

big deviation in control range

of adaptation values through

fuel and air mixture formation

When recognition the short

term fuel trim that more than

nominal threshold

When recognition the short

term fuel trim that less than

nominal threshold

When recognition the long

term fuel trim exceeds rich

threshold

When recognition the long

term fuel trim exceeds lean

threshold

When recognition the long

term fuel trim exceeds rich

threshold

When recognition the long

term fuel trim exceeds lean

threshold

When recognition the long

term fuel trim exceeds rich

threshold

When recognition the long

term fuel trim exceeds lean

threshold

•

Inspection the intake air leakage

•

Inspection the injection quantities with

injector block or leakage

•

Inspection the exhaust leakage

•

Inspection the ECM

81

93

96

97

98

99

100

101

102

103

Circuit Description

In order to control emissions, a catalytic converter is used to covert harmful emissions into harmless water vapor

and carbon dioxide. The ECM has the ability to monitor this process by using a oxygen sensor. The oxygen

sensor produces and output signal which indicates the storage capacity of the catalyst. This in turn indicates the

catalyst’s ability to convert exhaust emission effectively. If the oxygen sensor pig tail wiring, connector, or

terminal is damaged. Do not attempt to repair the wiring, connector, or terminals. In order for the sensor to

function properly, it must have a clean air reference provided to it. This clean air reference is obtained by way of

the oxygen sensor wire(s). Any attempt to repair the wires, connector, or terminal and degrade the oxygen sensor

performance.