SsangYong Rexton. Service manual - part 375

SSANGYONG Y200

1B3-76 DIESEL ENGINE MECHANICAL

YAD1BF20

YAD1BF30

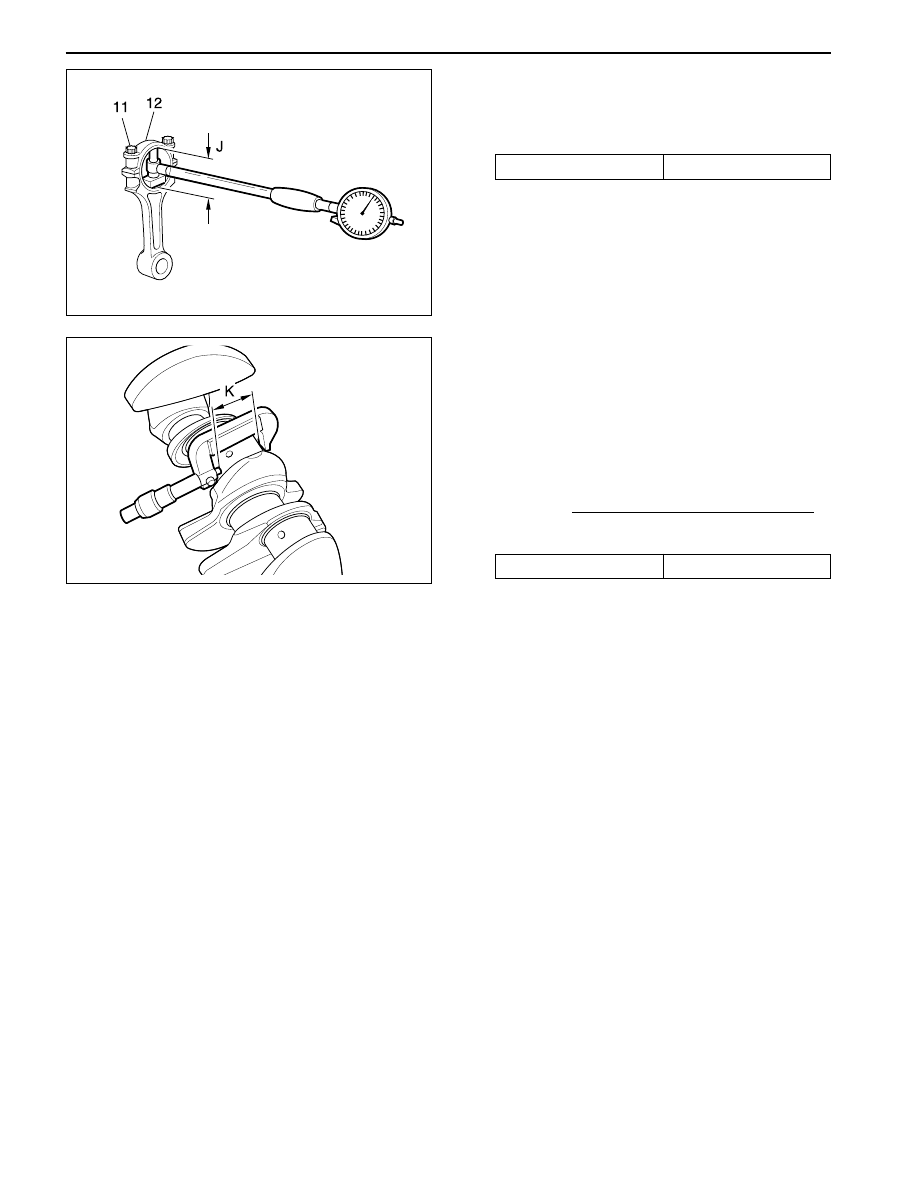

26. Measure connecting rod bearing journal diameter

(K).

Notice: Refer to measurement of the crankshaft

bearing journal diameter.

27. Measure the radial clearance (L) of the connecting

rod bearing.

Example) Measured value ‘J’ = 47.700 mm

Measured value ‘K’ = 47.653 mm

Clearance ‘L’

= 0.047 mm

Notice: If the clearance is out of standard, adjust

the radial clearance of connecting rod bearing by

replacing the connecting rod bearing shells.

28. Remove the connecting rod bearing cap.

29. Install the piston.

30. Rotate the crankshaft by hand and check whether

it rotates smoothly.

31. If the bearings are damaged,

- replace the oil presser relief valve.

- clean the oil pump and oil filter housing carefully

and replace the hose if necessary.

Notice: After assembling the engine, check the

camshaft timing, adjust the start of fuel injection

and check the TDC sensor bracket setting.

32. Fill oil and run the engine and then check the oil

pressure and oil level.

Notice: Install the original oil filter element and

then change the engine oil and oil filter element

after 1,000 - 1,500 km.

Tightening Torque

35 N•m (26 lb-ft)+ 90°

24. Insert the new connecting rod bearing shells into

the connecting rod and connecting rod bearing

cap and tighten the 12-sided stretch bolts (11).

Installation Notice

25. Measure inner diameter of connecting rod bearing.

Radial Clearance ‘L’

0.026 - 0.068 mm