SsangYong Rexton. Service manual - part 289

ELECTRICAL WIRING DIAGRAMS 5-189

SSANGYONG REXTON XDi (LHD)

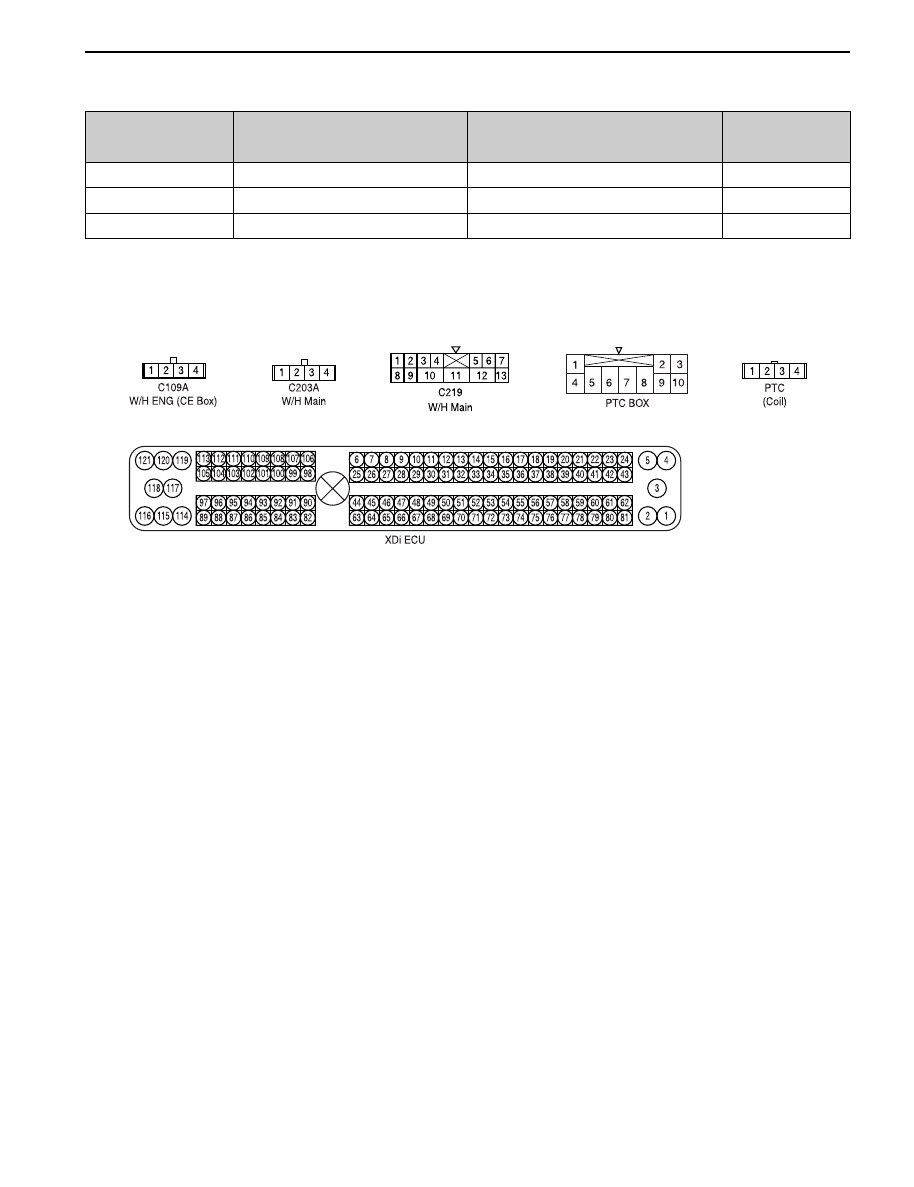

A. CONNECTOR INFORMATION

Connector Number

(Pin Number, Color)

Engine - Starter “ST”

Main - Floor (LH)

Engine - Main (RH)

C110 (1Pin, Gray)

C204 (12Pin, Black)

C219 (13Pin, Green)

Connecting Wiring

Harness

FRT Pre-Heating Unit

Inside Driver Side Cowl PNL

Inside Co-Driver Side Cowl PNL

A/T

Remark

Connector Position

B. CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION