Dacia Pick-Up 1304/1305/1307. Service manual - part 60

MANUAL GEARBOX

21

21 - 46

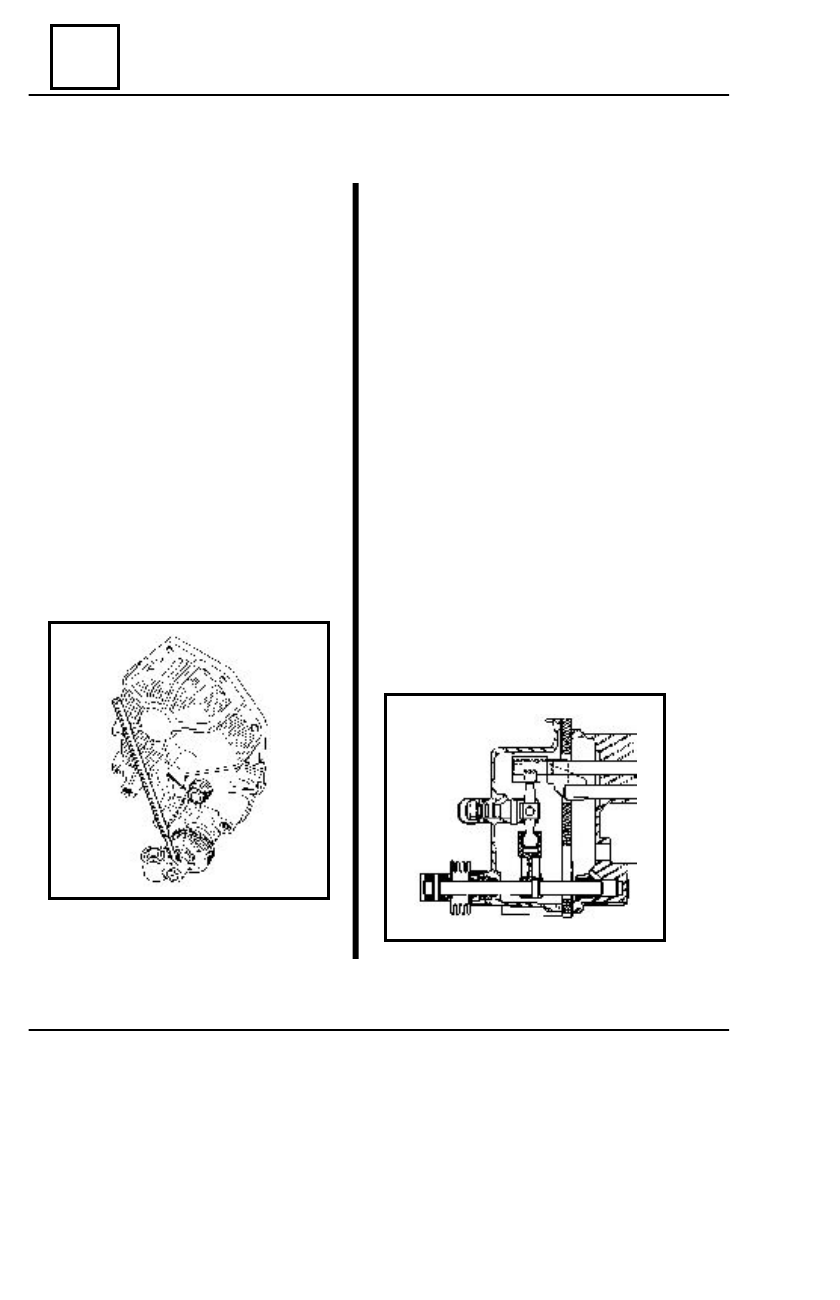

CONTROL SHAFT ANNULAR OIL SEAL REPLACEMENT

Lift the car on the elevator.

Drain the oil from the gearbox.

Dismount the back crossbar of the

gearbox.

For G.B. 50C and G.B.51 C:

- disengage the cardan transmission;

- dismount the flange of secondary

shaft.

Dismount the back cap.

Unscrew the nut from the end of the

rocking lever shaft.

Dismount the elastic pin from the control

shaft end.

Dismount together :

- the control shaft;

- the rocking lever and shaft.

Dismount the worm annular oil seal.

D

ISMO UNTING

R

EMOUNTING

Mount the new annular oil seal,after it was

immersed in 80W90 oil.

Mount together :

- the rocking lever shaft;

- the control shaft.

Tighten the attachment nut of the rocking le-

ver shaft, at the required couple (4 - 4,5 daNm).

Mount the rubber protection.

Mount on the control shaft :

- the protection bellow;

- the control shaft end;

- the elastic pin.

Mount the back cap with a new lubricated

gasket.

Mount the back crossbar of the gearbox.

Mount the flange of secondary shaft and

connect the cardan transmission (G.B.50C,G.B.

51C)

Check the velocity steps control mechanism.

Fill up the gearbox with 80W90 oil.

Lower the vehicle from the elevator.

(on vehicle )