Nissan Versa Note. Instruction - part 396

EM-100

< UNIT DISASSEMBLY AND ASSEMBLY >

[HR16DE]

CYLINDER BLOCK

Install the rear oil seal after installing the oil pan (upper).

17. Install rear oil seal. Refer to

EM-74, "REAR OIL SEAL : Removal and Installation"

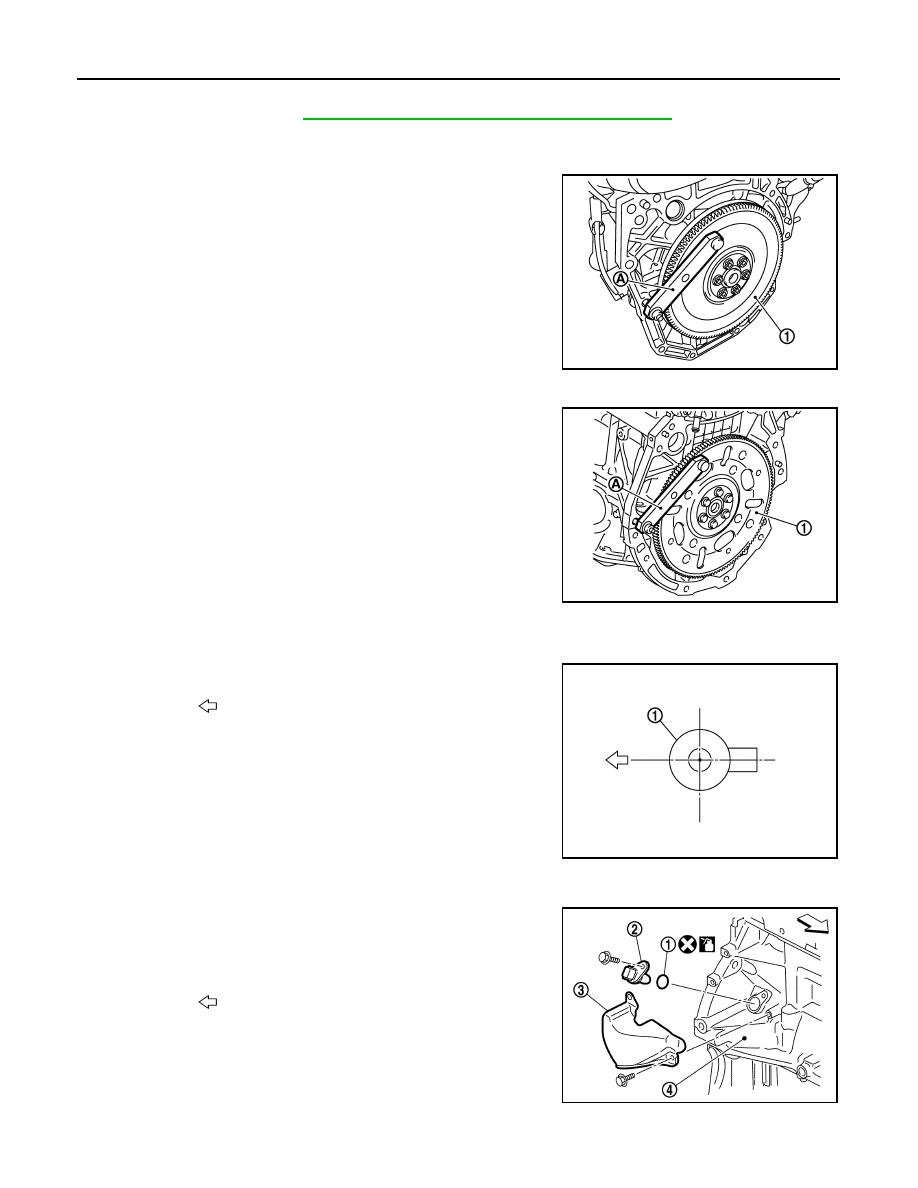

18. Install flywheel (M/T models) or drive plate (CVT models).

M/T models

• Secure crankshaft with a stopper plate (A) and tighten bolts

crosswise over several times.

CVT models

• Secure crankshaft with a stopper plate (A) and tighten bolts

crosswise over several times.

CAUTION:

Do not damage or scratch and contact surface for clutch disc of flywheel.

19. Install knock sensor (1).

• Install connectors so that they are positioned toward the rear

of the engine.

CAUTION:

• Do not tighten bolt while holding the connector.

• If any impact by dropping is applied to knock sensor,

replace it with a new one.

NOTE:

• Check that there is no foreign material on the cylinder block

mating surface and the back surface of knock sensor.

• Check that knock sensor does not interfere with other parts.

20. Install crankshaft position sensor (POS) (2) and O-ring (1) and

then install the crankshaft position sensor cover (3) on the cylin-

der block (4).

• Tighten bolts with sensor inserted completely.

CAUTION:

• Avoid impacts such as a dropping.

• Do not disassemble.

• Keep sensor away from metal particles.

• Do not place the sensor in a location where it is exposed

to magnetism.

• Do not reuse O-ring.

(1) :Flywheel

Tool number

: KV11105210 (J-44716)

MBIB1382E

(1) :Drive plate

Tool number

: KV11105210 (J-44716)

PBIC3226J

: Engine front

: Engine front

PBIC3754E

JPBIA4202ZZ