Nissan Versa Note. Instruction - part 394

EM-92

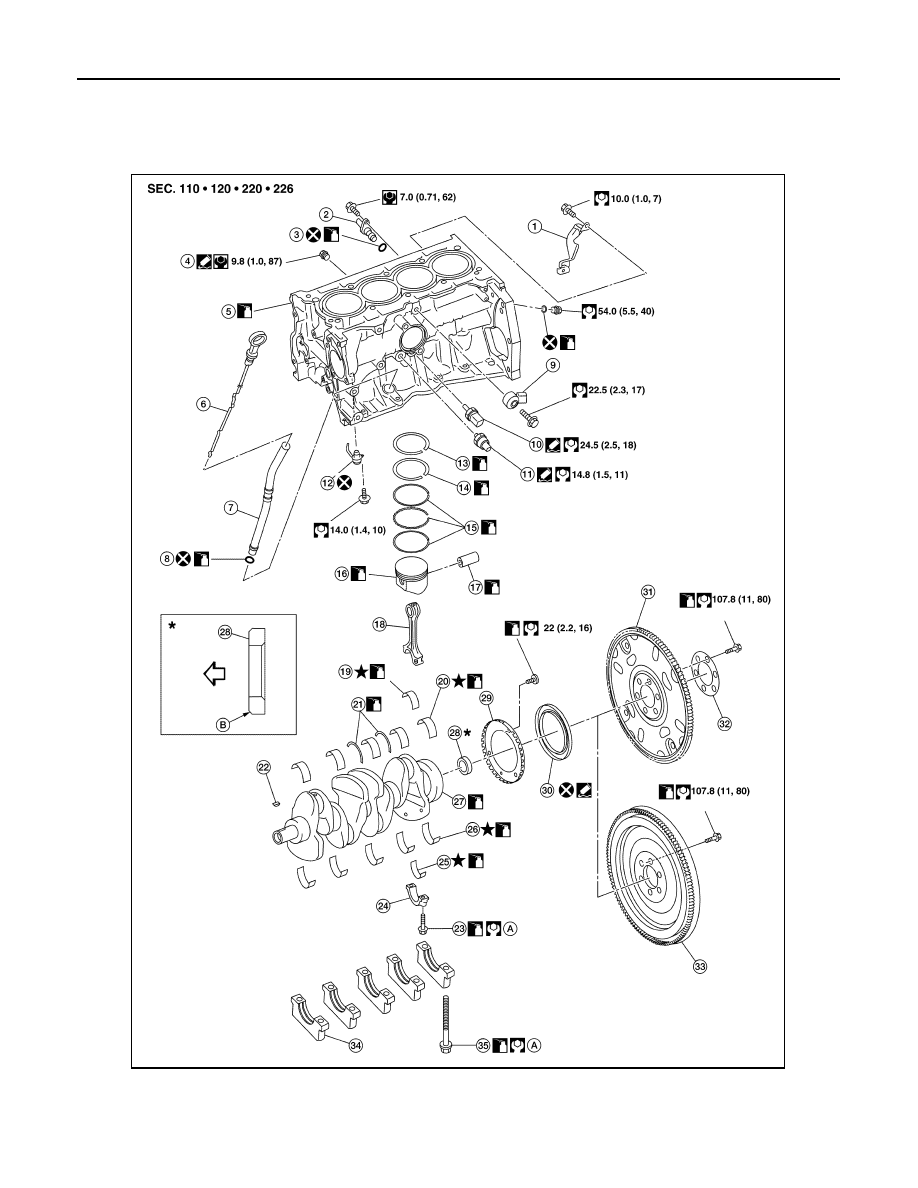

< UNIT DISASSEMBLY AND ASSEMBLY >

[HR16DE]

CYLINDER BLOCK

CYLINDER BLOCK

Exploded View

INFOID:0000000009444753

1.

Crankshaft position sensor cover

2.

Crankshaft position sensor (POS)

3.

O-ring

4.

Drain plug

5.

Cylinder block

6.

Oil level gauge

7.

Oil level gauge guide

8.

O-ring

9.

Knock sensor

AWBIA1621ZZ