Nissan Versa Sedan. Instruction - part 874

TM-402

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F11A]

P1588 G SENSOR

P1588 G SENSOR

DTC Logic

INFOID:0000000009268217

DTC DETECTION LOGIC

NOTE:

DC stands for "DRIVING CYCLE" and indicates a series of driving cycle of "Ignition switch OFF

→ ON → driv-

ing

→ OFF".

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.

PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT

1. Start the engine.

2. Select “Data Monitor” in “TRANSMISSION”.

3. Select “G SPEED”.

4. Drive the vehicle.

5. Maintain the following conditions for 10 seconds or more.

6. Stop the vehicle.

CAUTION:

Never stop the engine.

7. Repeat steps 4 through 6.

8. Check the DTC.

Is “P1588” detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009268218

1.

CHECK G SENSOR SIGNAL

With CONSULT

1. Park the vehicle on a level surface.

2. Turn ignition switch ON.

3. Select “Data Monitor” in “TRANSMISSION”.

4. Select “G SEN SLOPE”.

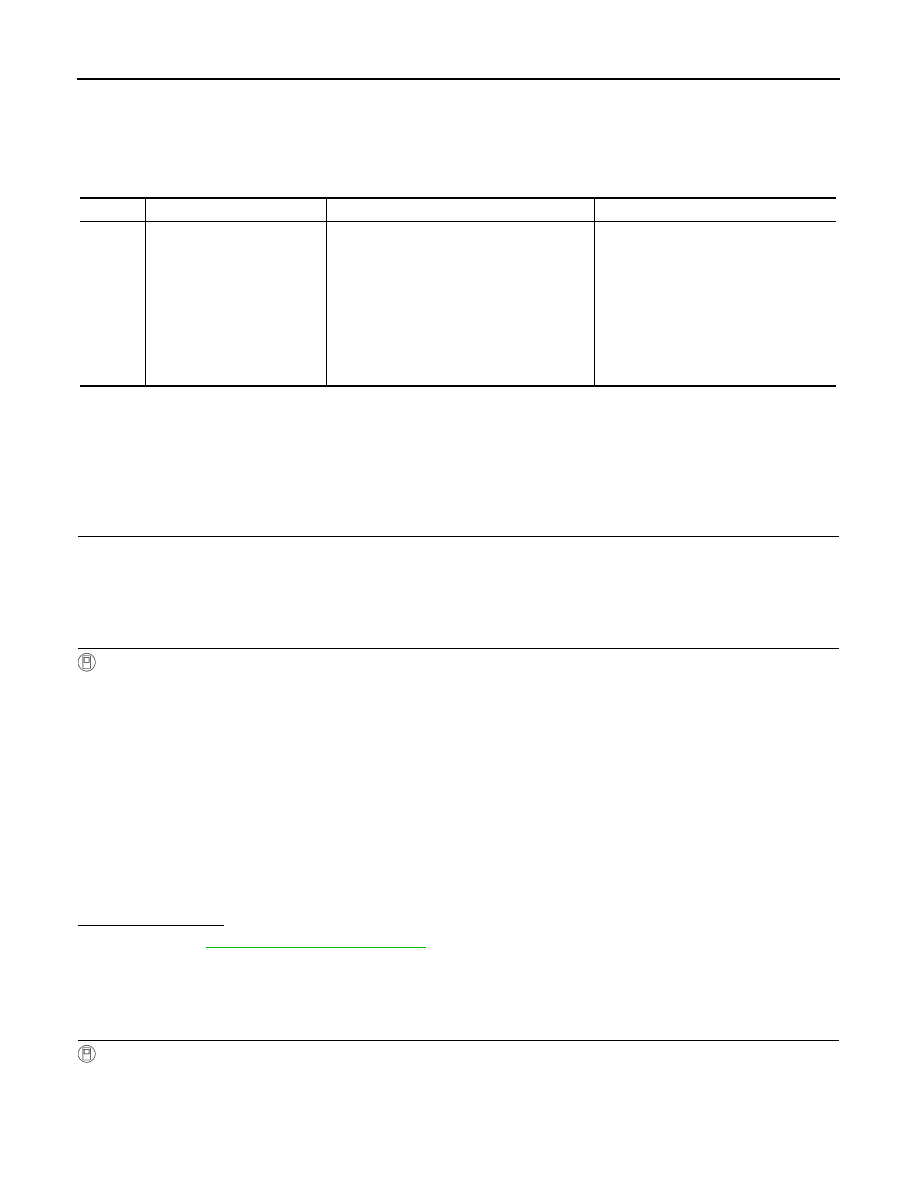

DTC

Trouble diagnosis name

DTC detection condition

Possible causes

P1588

G Sensor Circuit Range/Per-

formance

When the following diagnosis conditions are

satisfied and the detection conditions are sat-

isfied twice in the same DC:

• Diagnosis condition (1 second or more)

- The rate of change in G sensor detection

value (mV): Between

−15 and +15 inclusive

• Detection condition

- The rate of change in acceleration/deceler-

ation stays +0.0273 G or more/

−0.0273 or

less at least for 5 seconds or more.

G sensor

Selector lever

: “D” position

G SPEED

: 0.05 G or more