Nissan Versa Sedan. Instruction - part 838

TM-258

< PRECAUTION >

[CVT: RE0F11A]

PRECAUTIONS

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the battery cable from the negative terminal

before any repair or inspection work. The open/short circuit of related switches, sensors, solenoid

valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Removal and Installation Procedure for CVT Unit Connector

INFOID:0000000009268055

REMOVAL

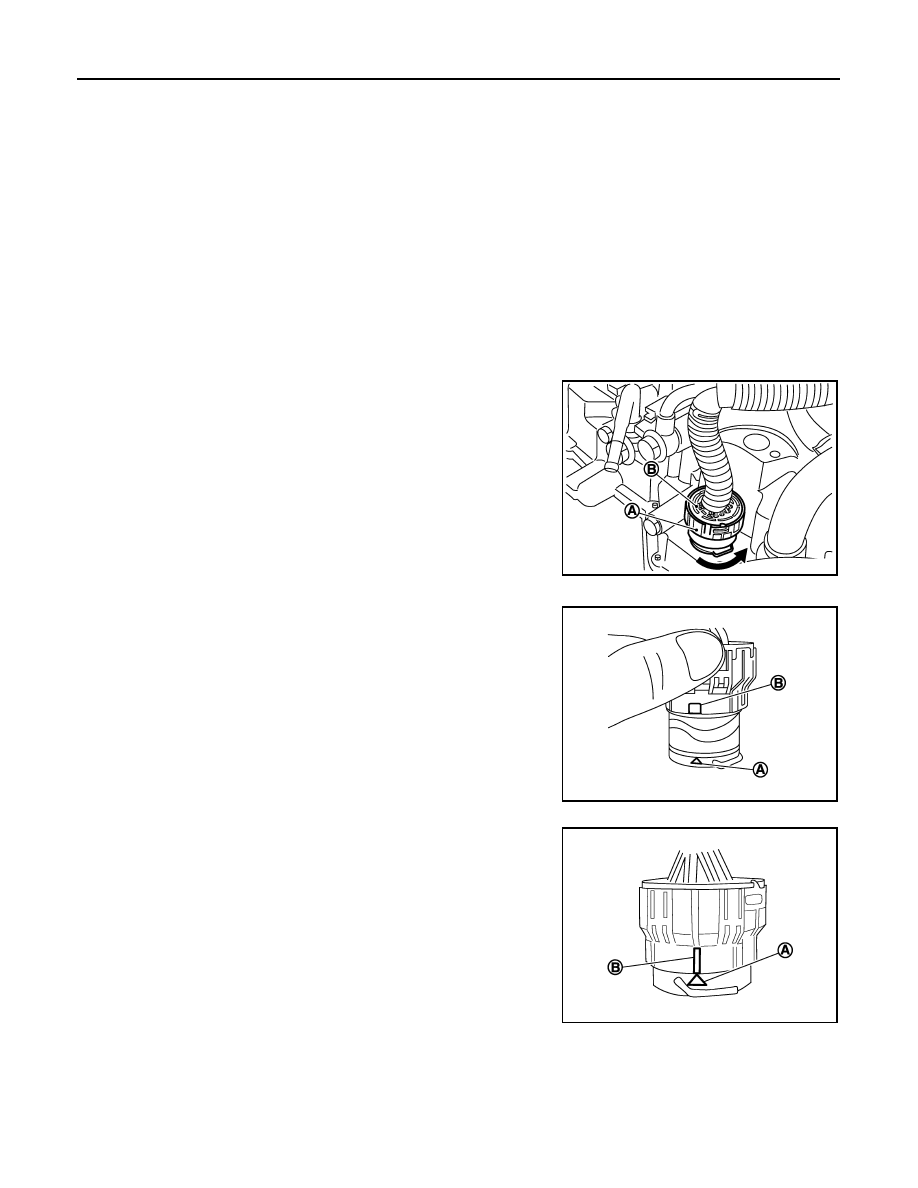

• Rotate bayonet ring (A) counterclockwise. Pull out CVT unit har-

ness connector (B) upward and remove it.

INSTALLATION

1. Align marking (A) on CVT unit harness connector terminal with

marking (B) on bayonet ring. Insert CVT unit harness connector.

2. Rotate bayonet ring clockwise.

3. Rotate bayonet ring clockwise until marking (A) on CVT unit har-

ness connector terminal body is aligned with the slit (B) on bayo-

net ring as shown in the figure (correctly fitting condition).

CAUTION:

JSDIA1162ZZ

JPDIA0294ZZ

JPDIA0295ZZ