Nissan Versa Sedan. Instruction - part 806

TM-130

< BASIC INSPECTION >

[4AT: RE4F03C]

LINE PRESSURE TEST

LINE PRESSURE TEST

Work Procedure

INFOID:0000000009267880

INSPECTION

1. Inspect the amount of engine oil. Replenish the engine oil if necessary. Refer to

.

2. Drive for about 10 minutes to warm up the vehicle so that the A/T fluid temperature is to 50 to 80

°C (122

to 176

°F).

3. Inspect the amount of ATF. Replenish if necessary. Refer to

.

4. Remove fluid pressure detection plug.

5. Install the joint pipe adapter [SST: KV31103600 ( — )],

adapter [SST: 25054000 (J-25695-4)], and oil pressure gauge

set (commercial service tool).

NOTE:

When using oil pressure gauge, be sure to use O-ring attached

to fluid pressure detection plug.

6. Securely engage parking brake so that the tires do not turn.

7. Start the engine.

8. Measure the line pressure at both idle and the stall speed.

CAUTION:

Keep brake pedal pressed all the way down during measurement.

9. Install O-rig to fluid pressure detection plug.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

10. Install fluid pressure detection plug.

JUDGMENT

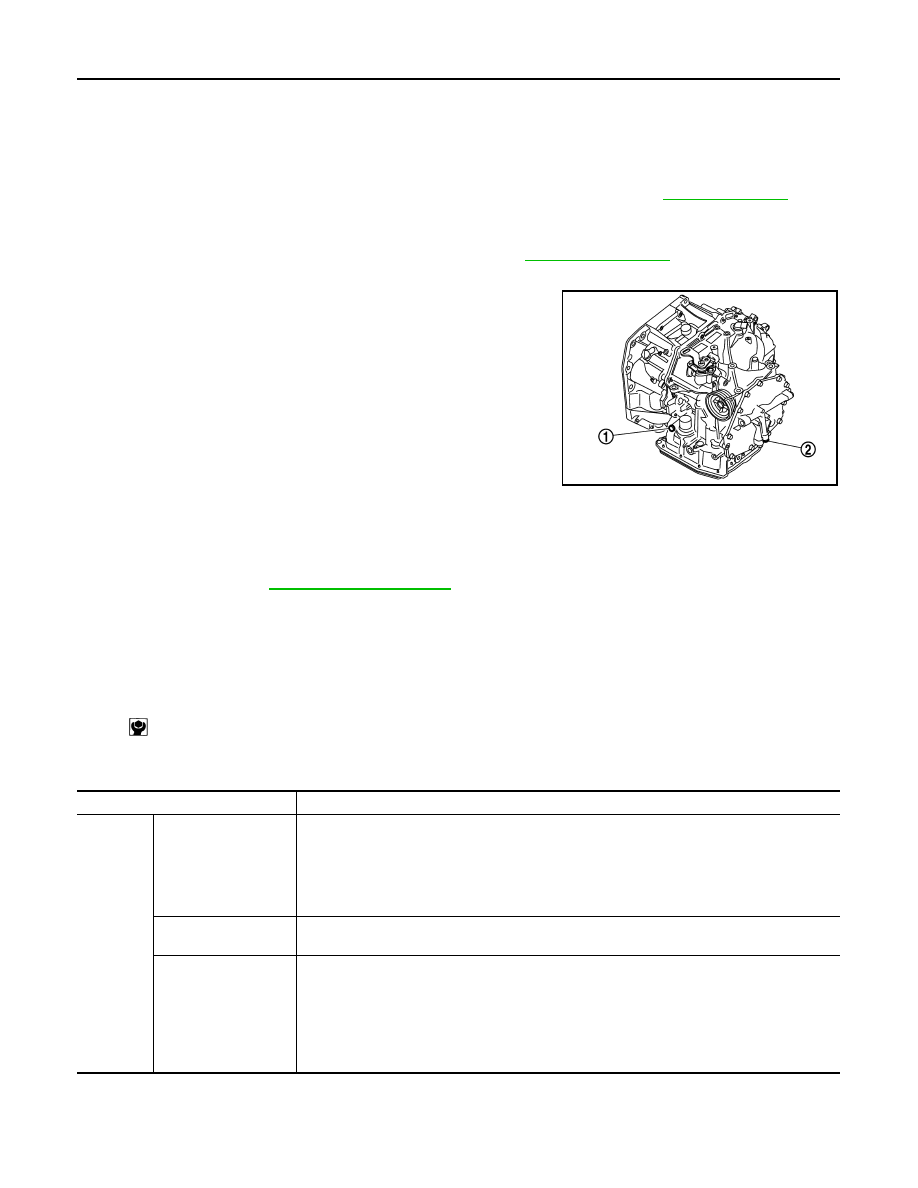

1

: “D” position fluid pressure detection plug

2

: “R” position fluid pressure detection plug

Line pressure

: 7.4 N·m (1.70 lb-m, 66 in-lb)

JSDIA2020ZZ

Judgment Possible

cause

Idle speed

Low for all positions

(“P”, “R”, “N”, “D”, “2”,

“1”)

Possible causes include malfunctions in the pressure supply system and low oil pump output.

For example

• Oil pump wear

• Pressure regulator valve or plug sticking or spring fatigue

• Oil strainer

⇒ oil pump ⇒ pressure regulator valve passage oil leak

• Engine idle speed too low

Only low for a specific

position

Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the instruction valve.

High

Possible causes include a sensor malfunction or malfunction in the line pressure adjustment

function.

For example

• Accelerator pedal position signal malfunction

• Line pressure solenoid malfunction (sticking in OFF state, filter clog, cut line)

• Pressure regulator valve or plug sticking

• Engine idle speed too high