Nissan Versa Sedan. Instruction - part 788

TM-58

< SERVICE DATA AND SPECIFICATIONS (SDS)

[5MT: RS5F91R]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

INFOID:0000000009267812

Transaxle type

RS5F91R

Engine type

HR16DE

Model code number

3AM0C

Number of speed

5

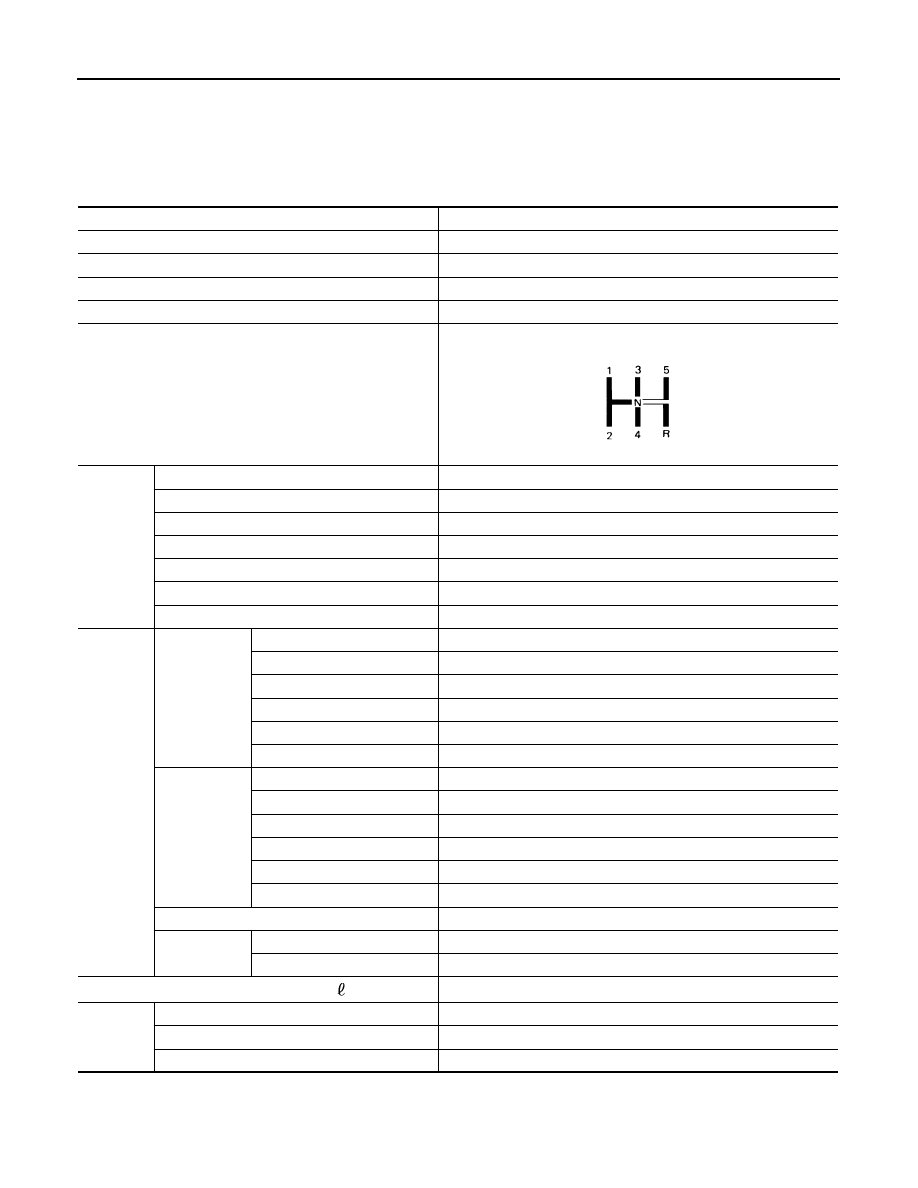

Synchromesh type

Warner

Shift pattern

Gear ratio

1st

3.7273

2nd

2.0476

3rd

1.3929

4th

1.0294

5th

0.8205

Reverse

3.5455

Final gear

4.0667

Number of

teeth

Input gear

1st

11

2nd

21

3rd

28

4th

34

5th

39

Reverse

11

Main gear

1st

41

2nd

43

3rd

39

4th

35

5th

32

Reverse

39

Reverse idler gear

26

Final gear

Final gear/Pinion

61/15

Side gear/Pinion mate gear

13/9

Oil capacity (Reference)

(US pt, Imp pt)

Approx. 2.67 (5-5/8, 4-3/4)

Remarks

Reverse brake

Installed

Double-cone synchronizer

1st and 2nd

Speedometer drive gear

Not installed

SCIA0821E