Nissan Versa Sedan. Instruction - part 586

MWI

B2268 WATER TEMP

MWI-43

< DTC/CIRCUIT DIAGNOSIS >

[TYPE A]

C

D

E

F

G

H

I

J

K

L

M

B

A

O

P

B2268 WATER TEMP

Description

INFOID:0000000009266597

The engine coolant temperature signal is transmitted from ECM to the combination meter via CAN communi-

cation.

DTC Logic

INFOID:0000000009266598

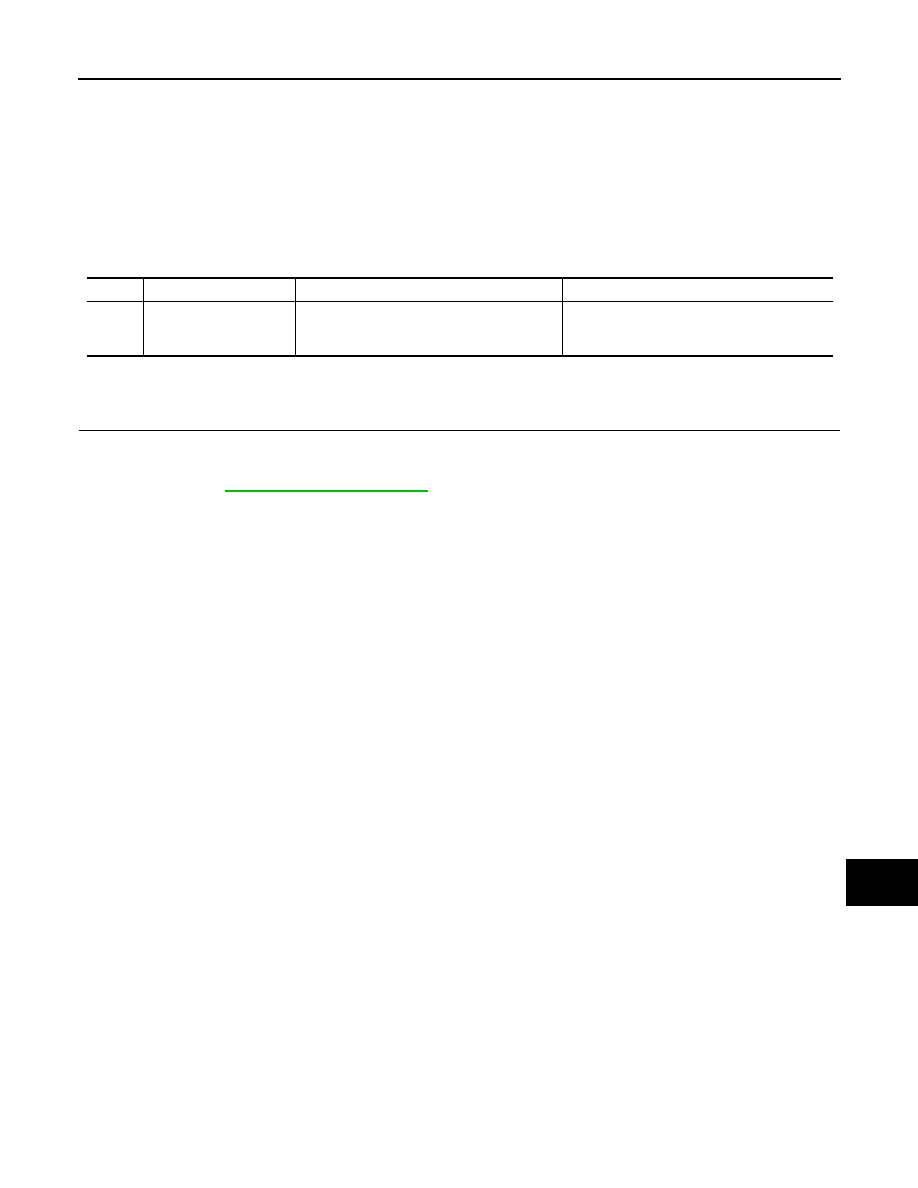

DTC DETECTION LOGIC

Diagnosis Procedure

INFOID:0000000009266599

1.

PERFORM SELF-DIAGNOSIS OF ECM

Perform “Self Diagnosis Result” of “ENGINE”, and repair or replace malfunctioning parts.

>> Refer to

.

DTC

CONSULT

Detection Condition

Possible malfunction location

B2268

WATER TEMP

ECM continuously transmits abnormal engine

coolant temperature signals for 60 seconds or

more

• Engine coolant temperature sensor

• ECM