Nissan Versa Sedan. Instruction - part 569

MA-34

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

ROAD WHEEL : Tire Rotation

INFOID:0000000009269073

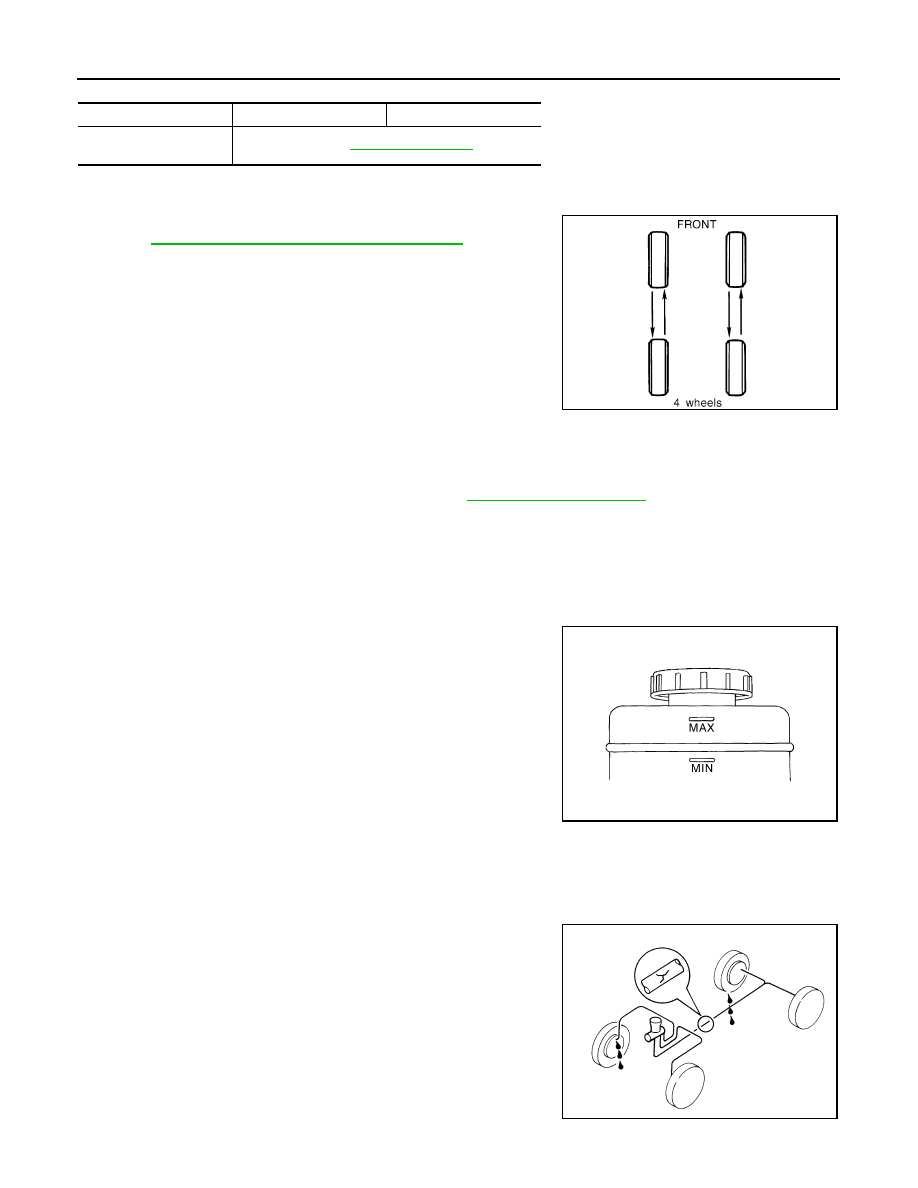

• Follow the maintenance schedule for tire rotation service intervals.

MA-6, "Explanation of General Maintenance"

• When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

• Do not include the T-type spare tire when rotating the tires.

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the

criteria for preventing strain of disc rotor.

• Use NISSAN genuine wheel nuts for aluminum wheels.

• Perform the ID registration, after tire rotation. Refer to

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAKS : Inspection

INFOID:0000000009269074

BRAKE FLUID LEVEL

• Check that the fluid level in the reservoir tank is within the specified

range between the MAX – MIN lines as shown.

• Visually check for any brake fluid leakage around the reservoir

tank.

• Check the brake system for any leakage if the fluid level is

extremely low (lower than MIN).

• Check the brake system for fluid leakage if the warning lamp

remains illuminated even after the parking brake is released.

• Check the reservoir tank for foreign matter (e.g., dust) and oils

other than brake fluid.

BRAKE LINES AND CABLES

BRAKE LINES AND CABLES : Inspection

INFOID:0000000009269075

BRAKE LINES

1. Check brake lines (pipes and hoses) for cracks, deterioration or

other damage. Replace any damaged parts.

2. Check for brake fluid leaks by fully depressing brake pedal while

engine is running.

CAUTION:

Retighten the applicable connection to the specified torque

and repair any abnormal (damaged, worn or deformed) part

if any brake fluid leaks are present.

PARKING BRAKE CABLES

Wheel balance

Dynamic (At flange)

Static (At flange)

Maximum allowable im-

balance

Refer to

.

SMA829C

Wheel nut tightening torque

: 113 N·m (12 kg-m, 83 ft-lb)

JPFIA0007ZZ

SBR389C