Nissan Versa Sedan. Instruction - part 498

COMPRESSOR DOES NOT OPERATE

HAC-47

< SYMPTOM DIAGNOSIS >

[MANUAL AIR CONDITIONING]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

COMPRESSOR DOES NOT OPERATE

Description

INFOID:0000000009269813

SYMPTOM

Compressor does not operate.

Diagnosis Procedure

INFOID:0000000009269814

NOTE:

• Perform self-diagnosis with CONSULT before performing symptom diagnosis. If any malfunction result or

DTC is detected, perform the corresponding diagnosis.

• Check that refrigerant system is fully charged. If the refrigerant charge is low, perform the inspection for

refrigerant leakage

1.

CHECK MAGNET CLUTCH OPERATION

Check magnet clutch. Refer to

HAC-42, "Component Function Check"

.

Does it operate normally?

YES

>> GO TO 2.

NO

>> Repair or replace malfunctioning parts.

2.

CHECK REFRIGERANT PRESSURE SENSOR

Check refrigerant pressure sensor. Refer to

EC-448, "Component Function Check"

.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace malfunctioning parts.

3.

CHECK A/C ON SIGNAL

Check A/C ON signal. Refer to

HAC-32, "Component Function Check"

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace malfunctioning parts.

4.

CHECK BLOWER FAN ON SIGNAL

Check blower fan ON signal. Refer to

HAC-35, "Component Function Check"

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace malfunctioning parts

5.

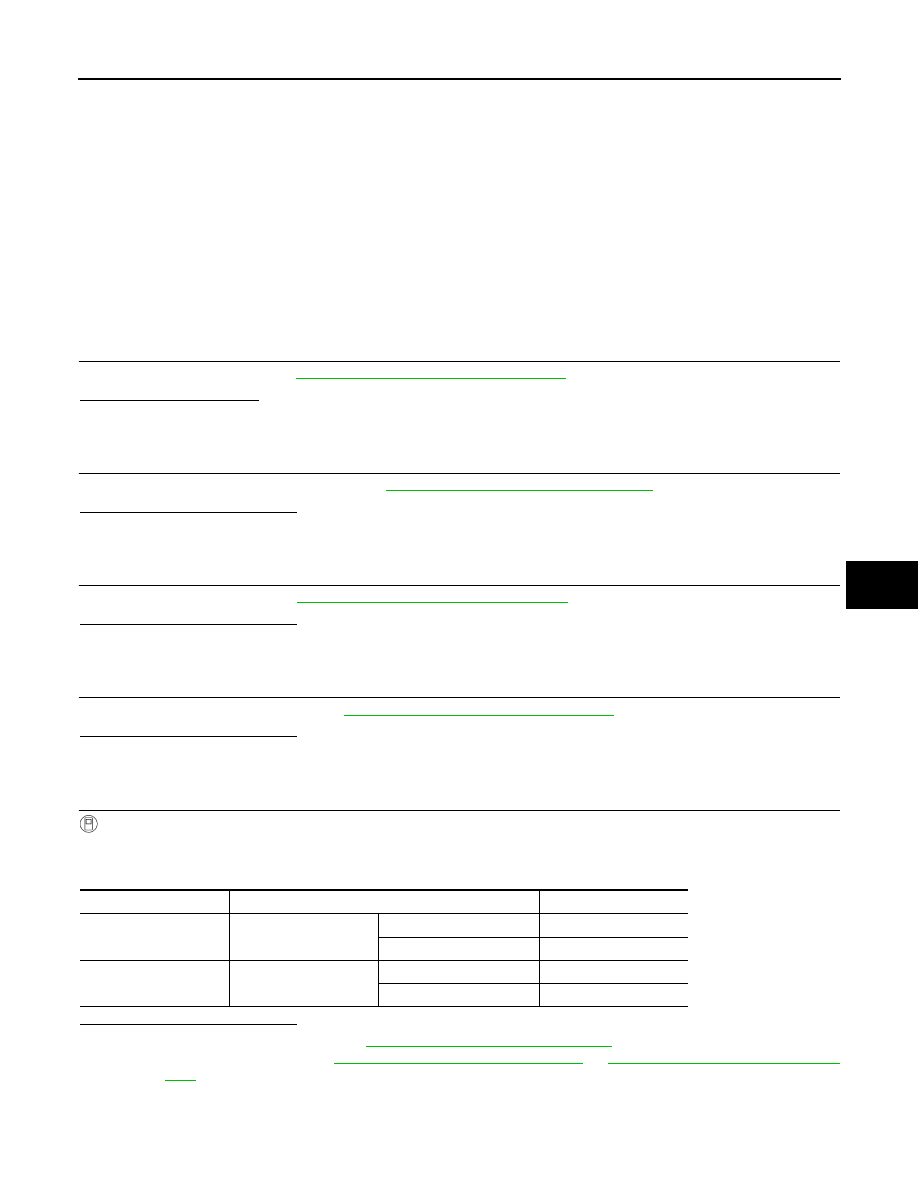

CHECK BCM OUTPUT SIGNAL

With CONSULT

1. Select “DATA MONITOR” mode of “ECM” using CONSULT.

2. Select “AIR COND SIG” and “HEATER FAN SW”, and check status under the following conditions.

Is the inspection result normal?

YES

>> Replace IPDM E/R. Refer to

PCS-56, "Removal and Installation"

.

NO

BCS-69, "Removal and Installation"

or

BCS-122, "Removal and Installa-

.

Monitor item

Condition

Status

AIR COND SIG

A/C switch

OFF (A/C indicator: OFF)

Off

ON (A/C indicator: ON)

On

HEATER FAN SW

Blower motor

OFF

Off

ON

On