Nissan Versa Sedan. Instruction - part 443

FAX-24

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Bearing

INFOID:0000000009268304

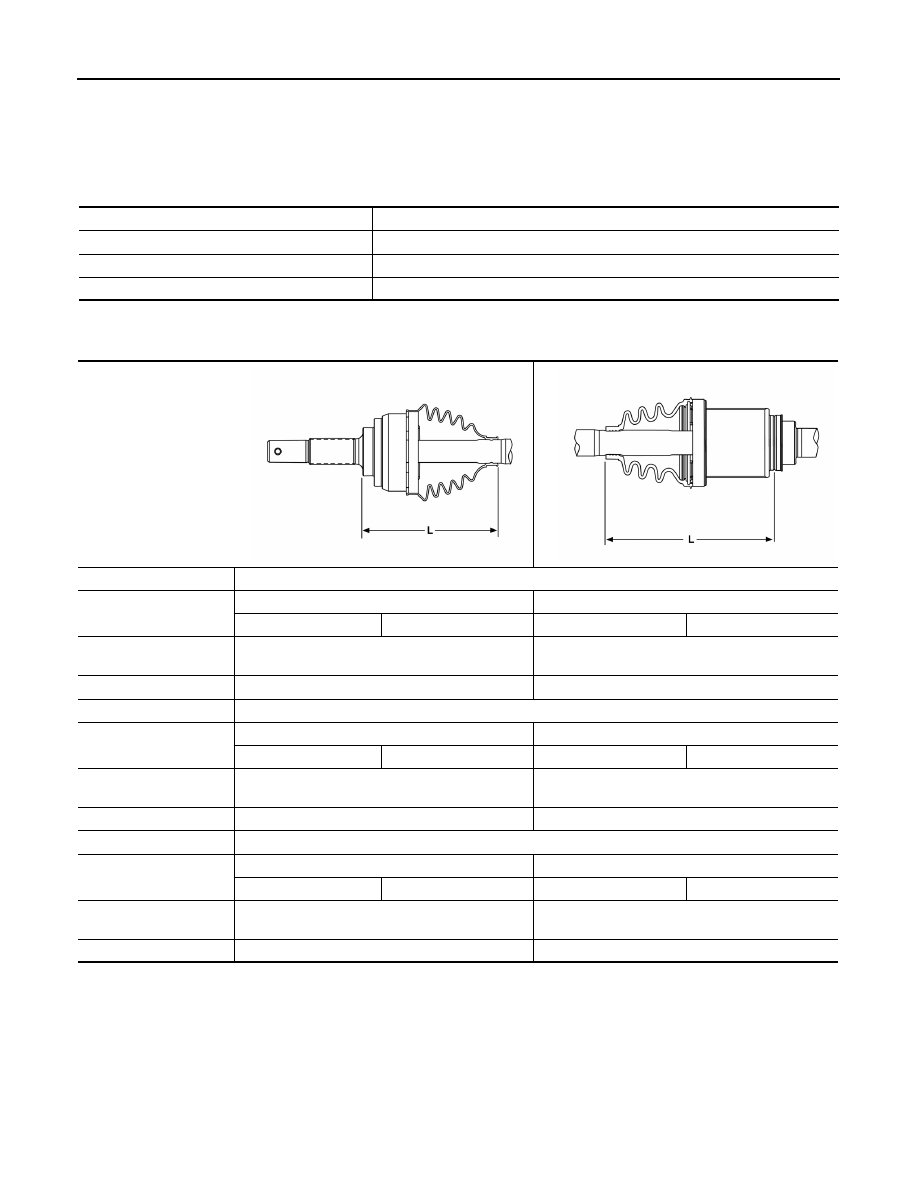

Drive Shaft

INFOID:0000000009268305

Item

Standard

Axial end play

0.055 mm (0.002 in) or less

Rotating torque

1.9 N·m (0.19 kg-m, 17 in-lb) or less

Spring balance measurement

13.7 N (1.40 kg-f, 3.08 lb-f) or less

Application

M/T

Joint type

Wheel side

Transaxle side

LH

RH

LH

RH

Grease quantity

90 - 100 g

(3.17 - 3.53 oz)

141.1- 157.1 g

(4.98 - 5.54 oz)

Boot installed length (L)

135.5 mm (5.33 in)

154 mm (6.06 in)

Application

CVT

Joint type

Wheel side

Transaxle side

LH

RH

LH

RH

Grease quantity

90 - 100 g

(3.17 - 3.53 oz)

132.7 - 148.7 g

(4.68 - 5.25 oz)

Boot installed length (L)

136.8 mm (5.39 in)

145.5 mm (5.73 in)

Application

A/T

Joint type

Wheel side

Transaxle side

LH

RH

LH

RH

Grease quantity

90 - 100 g

(3.17 - 3.53 oz)

132.7 - 148.7 g

(4.68 - 5.25 oz)

Boot installed length (L)

136.8 mm (5.39 in)

145.5 mm (5.73 in)

ALDIA0269ZZ

ALDIA0268ZZ