Nissan Versa Sedan. Instruction - part 442

FAX-20

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

b. Secure dynamic damper with bands in the specified position.

CAUTION:

Do not reuse bands.

2. Remove any old grease that exists on the housing.

3. Install dust shield.

CAUTION:

Do not reuse dust shield.

4. Install circlip to housing.

CAUTION:

Do not reuse circlip.

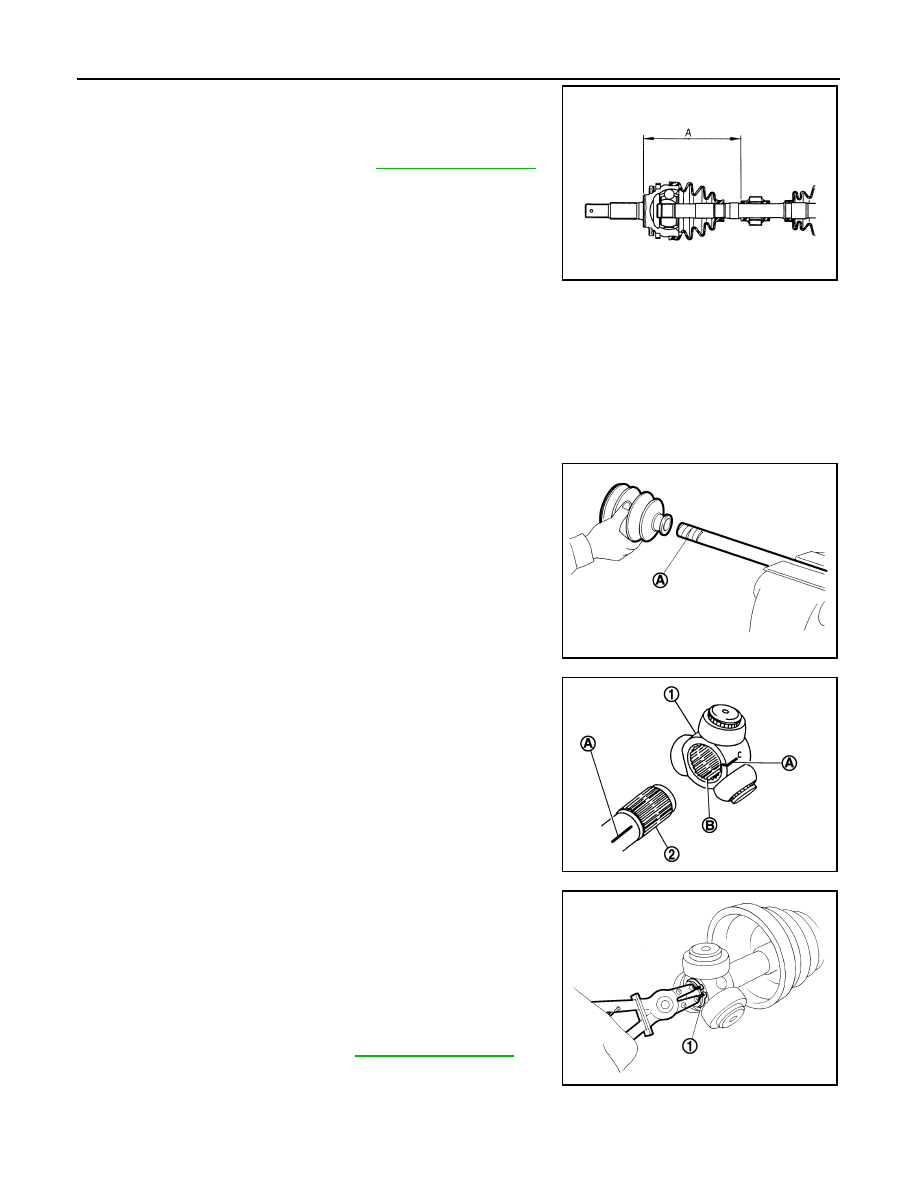

5. Install new boot and boot bands to shaft.

CAUTION:

• Wrap serration on shaft with tape (A) to protect boot from

damage.

• Do not reuse boot and boot bands.

6. Remove the tape wrapped around the serration on shaft.

7. To install the spider assembly (1), align it with the matching

marks (A) on the shaft (2) during the removal, and direct the ser-

ration mounting surface (B) to the shaft.

8. Secure spider assembly onto shaft with snap ring (1).

CAUTION:

Do not reuse snap ring.

9. Apply the appropriate amount of grease to spider assembly and

sliding surface.

10. Assemble the housing onto spider assembly, and apply the bal-

ance of the specified amount grease.

11. Align matching marks put during the removal of housing.

12. Install boot securely into grooves (indicated by “*” marks).

CAUTION:

Dimension (A)

: Refer to

JPDIF0178ZZ

JPDIF0009ZZ

JPDIF0017ZZ

Grease quantity

: Refer to

JPDIF0014ZZ