Nissan Versa Sedan. Instruction - part 375

OIL PAN (LOWER)

EM-35

< REMOVAL AND INSTALLATION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

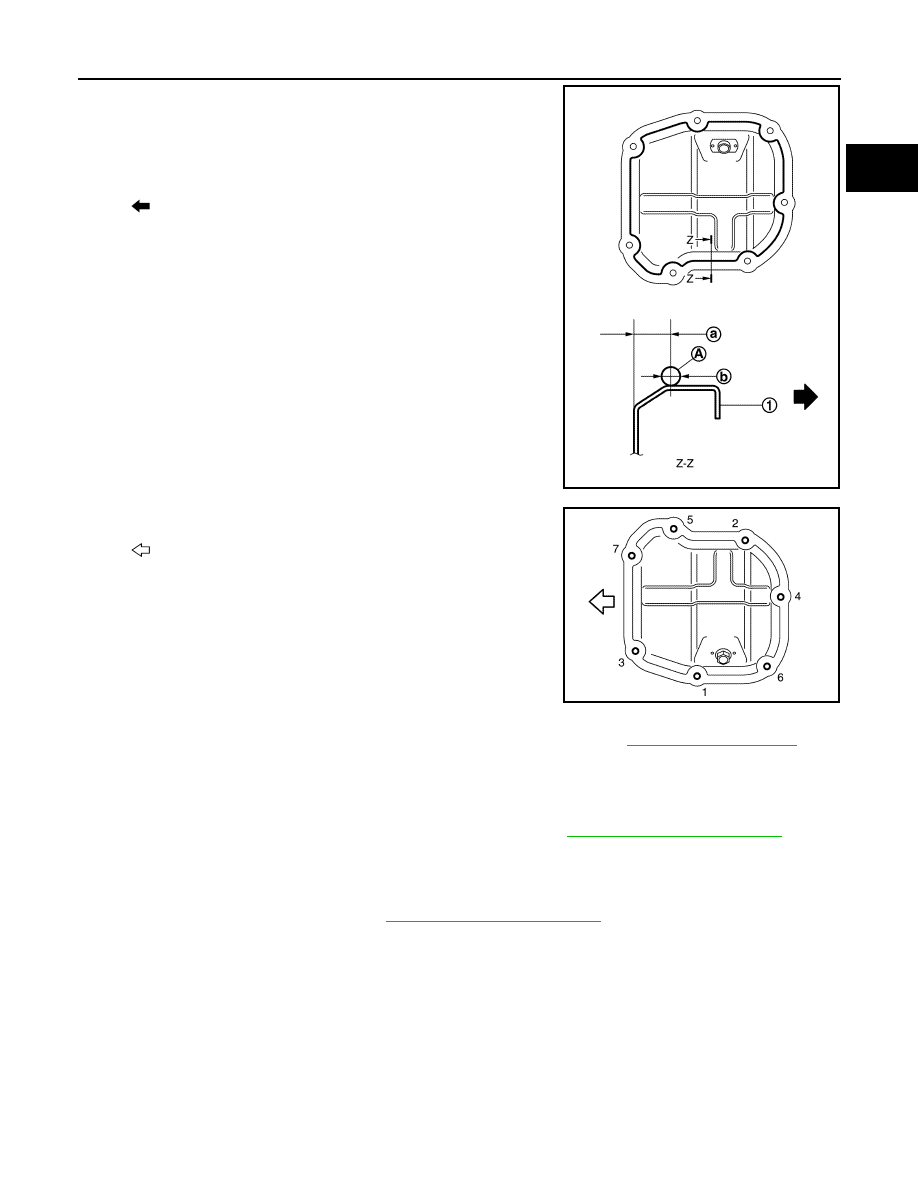

2. Apply a continuous bead of liquid gasket (A) with a tube presser

as shown.

Use Genuine Silicone RTV Sealant or equivalent.

CAUTION:

• The components must be installed within 5 minutes of the

liquid gasket application.

• Do not confirm torque after the 5 minutes have elapsed.

• Then allow 30 minutes for the liquid gasket to set before

adding oil to the engine.

3. Tighten bolts in numerical order as shown.

4. Install oil pan drain plug.

• Refer to the figure for installation direction of drain plug washer. Refer to

CAUTION:

• Installation should be done within 5 minutes after applying liquid gasket.

• Do not fill the engine with oil for at least 30 minutes after the oil pan (lower) is installed to allow

the sealant to cure.

5. Add the specified oil after waiting for at least 30 minutes. Refer to

MA-12, "Fluids and Lubricants"

.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels, including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to

MA-12, "Fluids and Lubricants"

.

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

(1)

: Oil pan (lower)

(a)

: 7.5 - 9.5 mm (0.295 - 0.374 in)

(b)

: 4.0 - 5.0 mm (0.157 - 0.197 in) diameter

: Engine outside

JSBIA1128ZZ

: Engine front

JSBIA1126ZZ