Nissan Versa Sedan. Instruction - part 365

EVAPORATIVE EMISSION SYSTEM

EC-459

< PERIODIC MAINTENANCE >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

EVAPORATIVE EMISSION SYSTEM

Inspection

INFOID:0000000009267329

1.

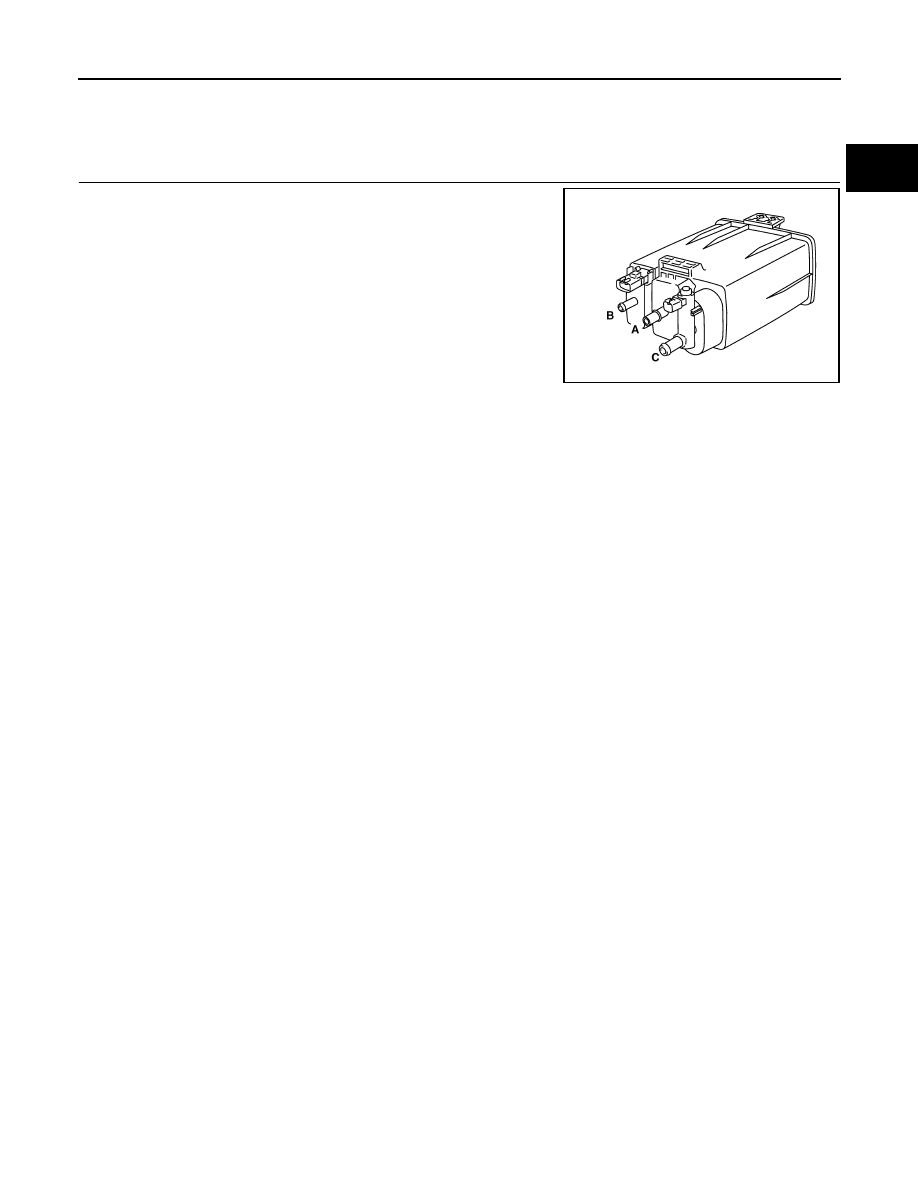

CHECK EVAP CANISTER

1. Block port (B).

2. Blow air into port (A) and check that it flows freely out of port (C).

3. Release blocked port (B).

4. Apply vacuum pressure to port (B) and check that vacuum pres-

sure exists at the ports (A) and (C).

5. Block port (A) and (B).

6. Apply pressure to port (C) and check that there is no leakage.

>> INSPECTION END

PBIB1212E