Nissan Versa Sedan. Instruction - part 258

SYSTEM

EC-31

< SYSTEM DESCRIPTION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

ENGINE CONTROL SYSTEM : System Description

INFOID:0000000009266989

ECM performs various controls such as fuel injection control and ignition timing control.

ENGINE CONTROL SYSTEM : Fail Safe

INFOID:0000000009619854

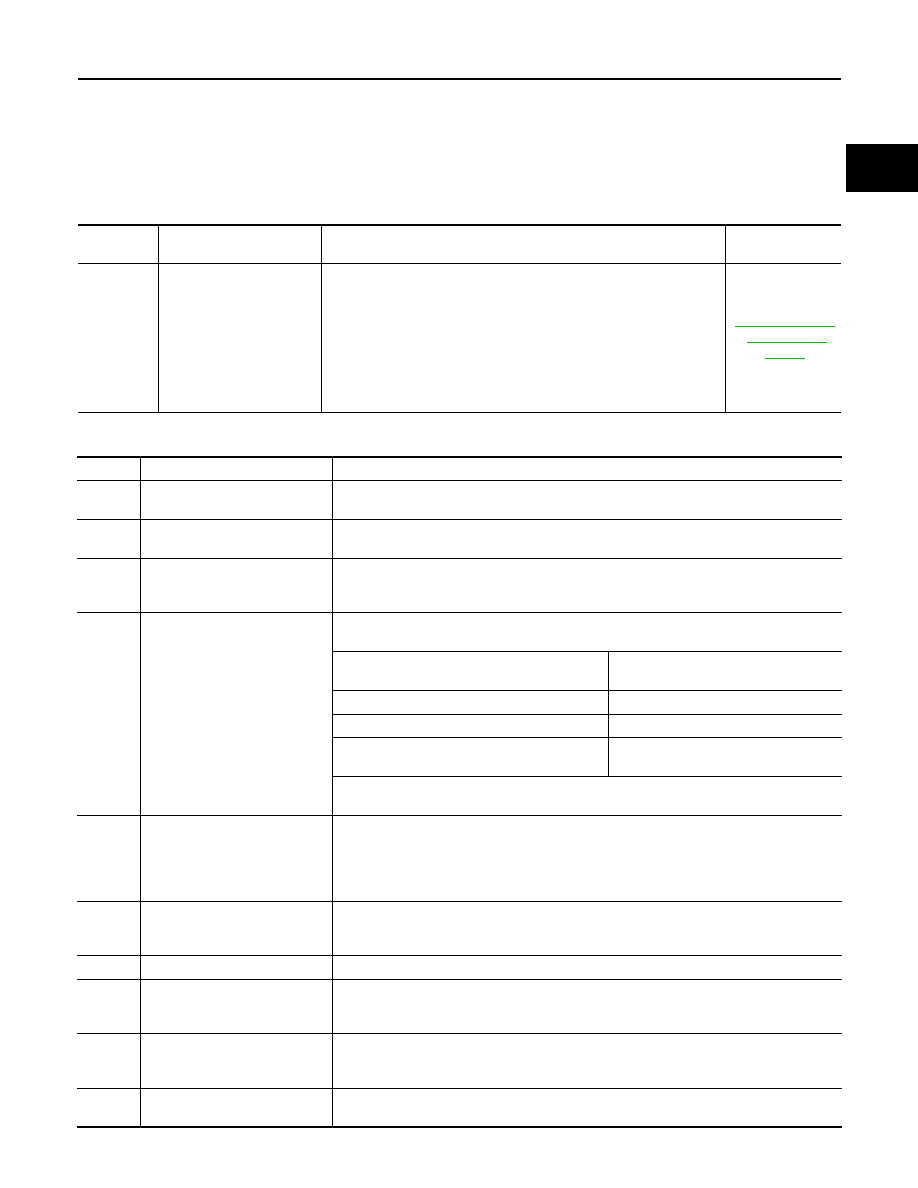

NON DTC RELATED ITEM

DTC RELATED ITEM

Detected

items

Engine operating condition

in fail-safe mode

Remarks

Reference page

Malfunction

indicator

lamp circuit

Engine speed will not rise

more than 2,500 rpm due

to the fuel cut

When there is an open circuit on MIL circuit, the ECM cannot warn the

driver by lighting up MIL when there is malfunction on engine control

system.

Therefore, when electrical controlled throttle and part of ECM related

diagnoses are continuously detected as NG for 5 trips, ECM warns the

driver that engine control system malfunctions and MIL circuit is open

by means of operating fail safe function.

The fail safe function also operates when above diagnoses except MIL

circuit are detected and demands the driver to repair the malfunction.

DTC No.

Detected items

Engine operating condition in fail safe mode

P0011

Intake valve timing control

The signal is not energized to the intake valve timing control solenoid valve and the valve

control does not function.

P0014

Exhaust valve timing control

The signal is not energized to the exhaust valve timing control solenoid valve and the valve

control does not function.

P0101

P0102

P0103

Mass air flow sensor circuit

Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0117

P0118

Engine coolant temperature

sensor circuit

Engine coolant temperature will be determined by ECM based on the following conditions.

CONSULT displays the engine coolant temperature decided by ECM.

Condition

Engine coolant temperature decided

(CONSULT display)

Just as ignition switch is turned ON or START

40

°C (104°F)

Approx. 4 minutes or more after engine starting

80

°C (176°F)

Except as shown above

40 - 80

°C (104 - 176°F)

(Depends on the time)

When the fail safe system for engine coolant temperature sensor is activated, the cooling

fan operates while engine is running.

P0122

P0123

P0222

P0223

P2135

Throttle position sensor

The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

P0196

P0197

P0198

Engine oil temperature sensor

Exhaust valve timing control does not function.

P0500

Vehicle speed sensor

The cooling fan operates (Highest) while engine is running.

P0524

Engine oil pressure

• ECM illuminates oil pressure warning lamp on the combination meter.

• Engine speed will not rise more than 4,000 rpm due to the fuel cut.

• Fail-safe is canceled when ignition switch OFF

→ ON.

P0605

ECM

(When ECM calculation function is malfunctioning:)

ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P0643

Sensor power supply

ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.