Nissan Pathfinder. Instruction - part 849

CHASSIS AND BODY MAINTENANCE

MA-35

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

CAUTION:

Do not start engine while checking oil level.

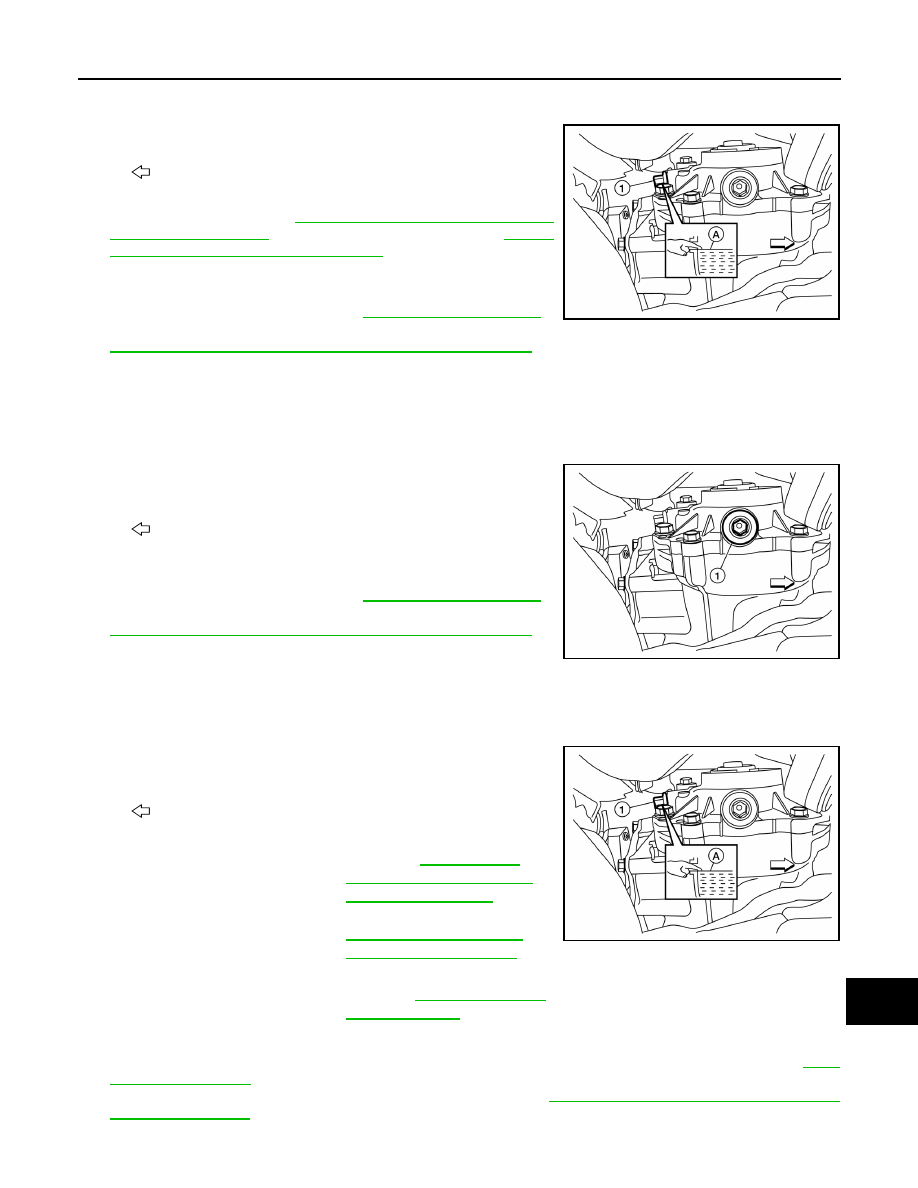

1. Remove filler plug (1).

2. Oil level (A) should be level with bottom of filler plug hole. Add

oil if necessary. Refer to

(United States and Canada) or

"FOR MEXICO : Fluids and Lubricants"

3. Clean threads of filler plug (1) and transfer case.

4. Apply sealant to the threads of the filler plug (1) and install it.

Tighten to specified torque. Refer to

Use Genuine Silicone RTV Sealant or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

.

TRANSFER OIL : Draining

INFOID:0000000009174192

CAUTION:

Do not start engine while checking oil level.

1. Run the vehicle to warm up the transfer unit sufficiently.

2. Stop the engine and remove drain plug (1) and drain the transfer

oil.

3. Clean threads of drain plug (1) and transfer case.

4. Apply sealant to the threads of the drain plug (1) and install it.

Tighten to specified torque. Refer to

Use Genuine Silicone RTV Sealant or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

.

TRANSFER OIL : Refilling

INFOID:0000000009174193

CAUTION:

Do not start engine while checking oil level.

1. Remove filler plug (1).

2. Fill with new oil to the specified level near the filler plug hole.

3. Clean threads of filler plug (1) and transfer case.

4. Apply sealant to the threads of the filler plug (1), and install it. Tighten to specified torque. Refer to

Use Genuine Silicone RTV Sealant or equivalent. Refer to

GI-22, "Recommended Chemical Prod-

.

: Front

ALDIA0383ZZ

: Front

ALDIA0382ZZ

: Front

Oil grade and viscosity

: Refer to

USA AND CANADA : Flu-

ids and Lubricants"

(Unit-

ed States and Canada) or

MA-16, "FOR MEXICO :

Fluids and Lubricants"

(Mexico).

Oil capacity

: Refer to

.

ALDIA0383ZZ