Nissan Pathfinder. Instruction - part 503

EC-318

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

DTC Logic

INFOID:0000000009178224

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Always perform test at a temperature of 5

°C (41°F) or more.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Turn ignition switch ON.

6. Select “DATA MONITOR” mode with CONSULT.

7. Check that “FUEL T/TMP SE” is more than 0

°C (32°F).

8. Start engine and wait at least 20 seconds.

9. Check 1st trip DTC.

With GST

1. Start engine and warm it up to normal operating temperature.

2. Set voltmeter probes to ECM harness connector terminals.

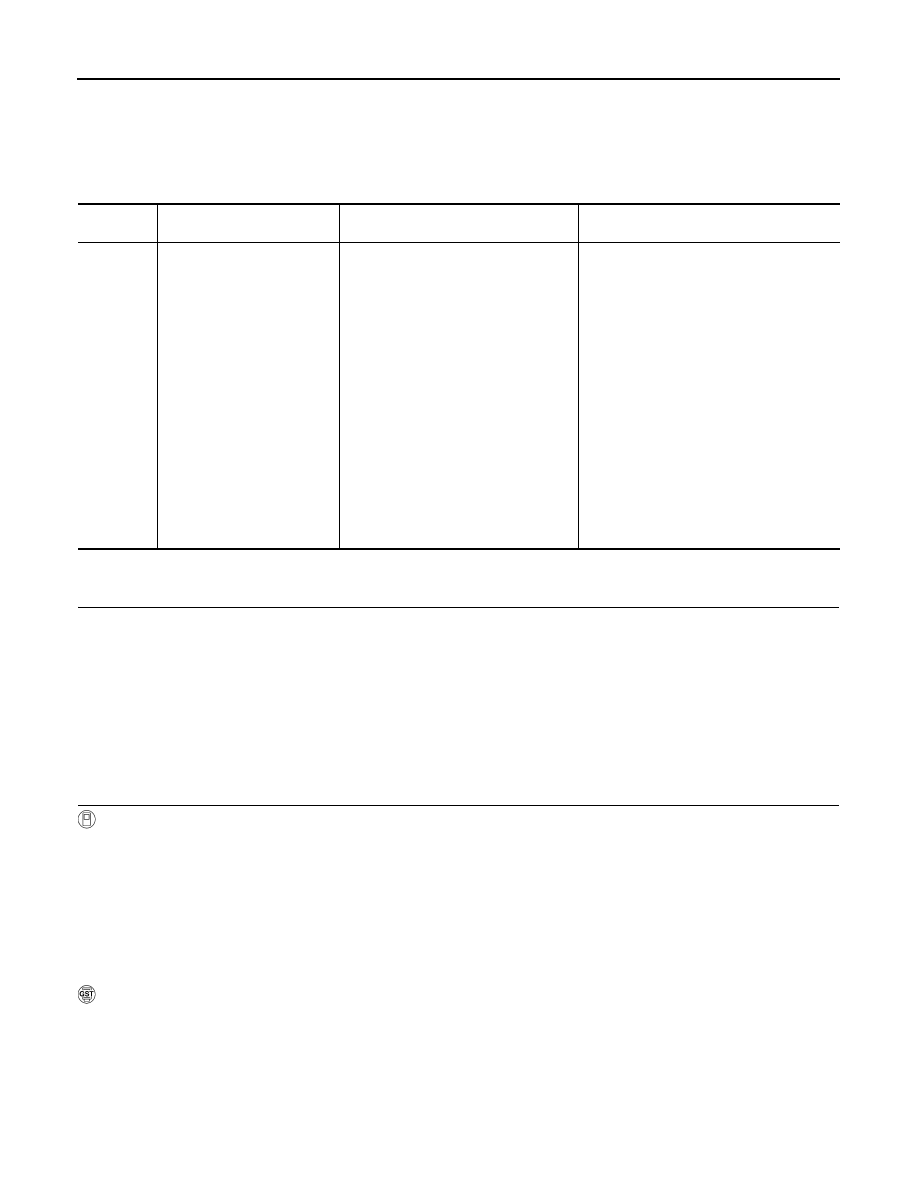

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0453

EVAP SYS PRES SEN

(Evaporative emission system

pressure sensor/switch high)

An excessively high voltage from the

sensor is sent to ECM.

• Harness or connectors

(EVAP control system pressure sensor cir-

cuit is open or shorted.)

[CKP sensor (POS) circuit is shorted.]

(APP sensor 2 circuit is shorted.)

(Refrigerant pressure sensor circuit is

shorted.)

(Engine oil pressure sensor circuit is short-

ed.)

• EVAP control system pressure sensor

• Crankshaft position sensor (POS)

• Accelerator pedal position sensor

• Refrigerant pressure sensor

• Engine oil pressure sensor

• EVAP canister vent control valve

• EVAP canister

• Rubber hose from EVAP canister vent

control valve to vehicle frame

• Sensor power supply 2 circuit