Nissan Pathfinder. Instruction - part 411

DLN-86

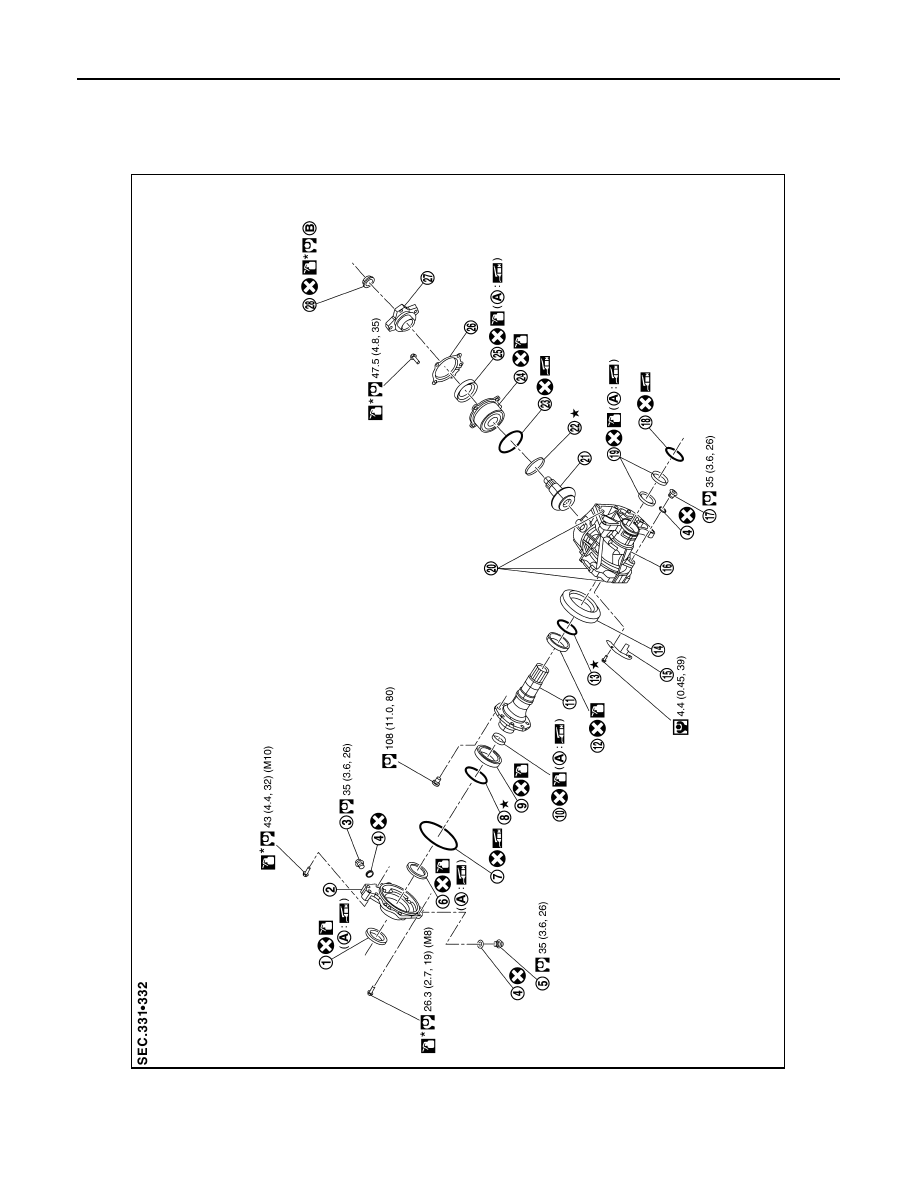

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY21C]

DRIVE PINION

DRIVE PINION

Exploded View

INFOID:0000000009177783

1.

Oil seal

2.

Transfer cover

3.

Filler plug

4.

Gasket

5.

Drain plug

6.

Oil seal

JSDIA4191GB